| Lugar sa Ginbuhat: | Shandong, China |

| Brand Name: | jinzheng |

| Model Number: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grade1、Grade3、Grade4、Grade6、Grade7、Grade8、Grade9、Grade10、Grade11 |

| Pagsusi: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| Minimum Order Quantity: | 1 ton |

| Presyo: | $650/ton |

| Detalye sa Pakete: | Standard sa Paghimo sa Ekspor (Sa mga bundle Nylon bags, mga kaso sa kahoy o sumala sa kinahanglan) |

| Panahon sa Paghatag: | 15-20 adlaw |

| Mga Tugnaw sa Paghimo: | FOB 30%T/T, 70% bago ang pagpadala |

| CIF 30% bayad ngatanan ug ang labawon ay pagbayad bago ang pagpadala | |

| o Irrevocable 100% L/C sa panahon nga makita | |

| Kadakuan sa Pagsubay: | 2000 Ton/Tons per Month |

Lingkon nga Detalye:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,tubong walang sikid,Seamless Carbon and Alloy Steel para sa Mekanikal na Tubing

Ang pipa sa dayon nga tubig A333 gamay ang gawas sa mga bidang kang petrokimiko, natural gas, kimika, elektrisidad, kag panul-on. Ang iyang daghan sa aplikasyon, maayong makalipay, Sa paghatag sa langis, natural gas, mga pipa kang sistema sa aircon, cooler, generator sa buhong-buhong, apan usahay gamiton sa pagproseso sa mekanikal, presyo sa konteyner, pagbuhat sa boiler, panginahanglan sa dayon nga bakal, dakong lugar, sentro sa ekspedisyon, lifting machinery, pagbuhat sa barko, storage shelves, dekorasyon, transportasyon sa fasilitad, pagnindangkon sa airport, bridge support, mine support, 3D parking, outdoor advertising, fitness equipment, Vehicle manufacturing ug uban pa

Kimikal na Kinahanglan

| Elemento | Komposisyon, % | ||||||||

| Grado 1A | Grado 3 | Grado 4 | Grado 6A | Grado 7 | Grado 8 | Grado 9 | Grado 10 | Grado 11 | |

| Carbon,max | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Manganese | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 max | 0.90 max | 0.40-1.06 | 1.15-1.50 | 0.60 makusog |

| Fosforo, makusog | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Sulphur, makusog | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Silicon | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 kaugalingon | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 daghanon |

| Nickel | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 daghanon | 35.0 -37.0 |

| Kromium | - | - | 0.44-1.01 | - | - | - | - | 0.15 max | 0.50 max |

| Tanso | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 max | - |

| Aluminum | - | - | 0.04-0.30 | - | - | - | - | 0.06max | - |

| Vanadium, max | - | - | - | - | - | - | - | 0.12 | - |

| Columbium, maks | - | - | - | - | - | - | - | 0.05 | - |

| Molybdenum, maks | - | - | - | - | - | - | - | 0.05 | 0.50 max |

| Cobalt | - | - | - | - | - | - | - | - | 0.50 max |

Kinakailangan sa Pagpaparami

| Bilang 1 | Grado 3 | Bilang 6 | Grado 7 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Katapusan sa pagpaparami, minProdukto sa katapusan, min | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Lungsod | Transwerse | Lungsod | Transwerse | Lungsod | Transwerse | Lungsod | Transwerse | |

| Pagpanulay sa 2 pulgada o 50mm, (o 40). minimum, %: Basiko nga minimum pagpanulay alang kan mura 5/16 in. (8 mm) ug ubos sa kapal, tesa test ug para sa tanan gamay mga gidaghanon nga gitest sa buong seksyon kada pangkalahongan nga bulatong 2-inta o 50-mm gage tugnaw o mas kaunti ang gidak-on gitest nga espesimen sa pagkabulat sa gage moadunay han 4D (4 beses sa diametro) mao ang ginamitPara sa mga test sa listahan, adunay bawasan para sa kada 1/32 in. [0.8 mm] ang paggamot sa tabok sa sulod sa 5/16 in. (8 mm) mula sa basic minimum elongation sa sumusunod nga porsyento |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| Grado 8 | Grado 9 | Grado 10 | Grado 11 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Katapusan sa pagpaparami, minProdukto sa katapusan, min | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Lungsod | Transwerse | Lungsod | Transwerse | Lungsod | Transwerse | Lungsod | ||

| Pagaplong sa 2 in. o 50mm, (o 40). min, %: Basiko minimum na pag-aba para sa mga pader 5/16 in. (8 mm) ug mas taas sa kapal, strip tests. Ug para sa tanan nga mga gamay nga laki nga gitest sa puno nga seksyon. Kapag standard round 2-in. o 50-mm gage length o proporsyonal nga mas gamay nga laki ang test specimen nga gamiton kon ang gage length mao ang 4D (4 beses sa diyametro) is gingamit. Sa mga strip tests, usa ka deduksyon para sa kada 1/32 in. [0.8 mm] decrease sa kapal sa pader ubos sa 5/16 in. (8 mm) mga basihan nga minimum nga pag-aba sunod-sunod nga百分百 |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Deskripsyon

1. Maikling pagkakita sa produkto

Ang low-temperature seamless steel pipe kay pangunahon nga gamit sa petroleum, kimika, natural gas ug coal ingon nga materyales sa ethylene, propylene, urea, synthetic ammonia, N-P-K composite fertilizer ug industriya sa mga gamot para sa paglalimpay, pagpulis, desulfurasyon ug pag-unlob sa produksyon, tanan pa usab sa paggawa sa kriyobiko nga kagamitan, ultra-low temperature storage, transport ultra-low temperature liquefied gas pipeline ug pipe components. Ang internasyonal nga sistema sa low-temperature seamless steel pipe kay representado pinaagi sa ASTM A333/A333M-2011 (dugangan usab nga Amerikanong standard), nga angkop sa kriyobiko nga kapaligiran hangtod -196℃. Sa una ka takna, ang produksyon ug pagtubag sa low-temperature seamless steel pipe sa kinaiyahan dayon naggamit sa Amerikanong standard, ug ang nasodnong disenyo usab nagtuton sa Amerikanong standard. Sa walo ka klase sa Amerikanong standard nga kriyobiko nga tubo, ang Gr.6 kay madamo nga ginamit sa petrokimiko nga industriya ug sa paghatag sa fluido sa kriyobiko ug malamig nga rehiyon, ug ang tuig-tuigang demand sa Amerika ug Europa nga market kay higit pa sa 20,000 t.

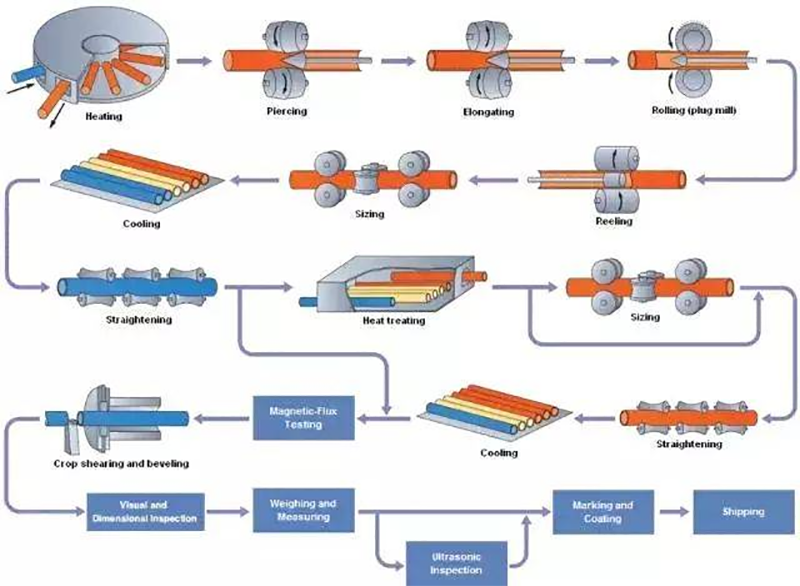

2. Proseso sa pag-gawa

Pag-gawa - Ang mga tube ay ginaaway pinaagi sa mga proseso sa pagweld na seamless o dili nagdadagdag sa filler metal. Ang lebel 4 kinahanglan angay sa seamless proseso.

Paghukom sa init

Ang tanan nga seamless ug welded pipes kinahanglan angay magpahukom sa init aron makontrol ang ilang mikroestraktura sa usa ka mga sumusunod nga mga paagi.

Kasagaran gininitaan hangtod dili liwat sa 1500F (815℃) alang sa positibong paghukom sa init, ug sunod-sunod cooling o pag-init sa chamber sa kontroladong hawngin oxygen furnace.

Ang steel pipe gininitaan ug ginireheat hangtod sa usa ka pasadyang tempering temperatura ingon nga nahatag sa steel mill. Ang pipereheating maayong nakontrol ang hot processing, samtang ang operating temperatura sa hot forming ginkontrol sa loob sa temperatura rango sa hot forming sa 1550 to 1750F (845-945 ° C), ug sunod-sunod it gikuha out sa kontroladong gas oxygen furnace uban sa usa ka pasadyang temperatura dili liwat sa 1550 (845 ° C). Kini paagi dako lang para sa non-sewn tube proseso.

Gisusi ug gibuhi uli kani sa tuigong temperatura sa pag-temper nga gitukoy sa fabrica.

Kadaghanan sa order, ang sample kinut-an gikan sa block sa pagsubok sa kalubong, nga gitabok gikan sa pipa sa bulak nga gi-triple heat, ug kinasosobra og presyon. Ang block sa pagsubok moadtoay mag-init ngadto sa gitukoyong temperatura, gimoisturize sa temperatura niining oras, ug sunod ha sunod gikulog hangtod sa temperatura nga dili mahimong mas taas pa kay 600F (315 ° C). Ang block sa pagsubok sa klase 8 pipa adunay i-air cool o i-water cool sa minimum nga rate sa pagkulog sa 300F/ (165℃/h) hangtod sa temperatura nga dili mahimong mas taas pa kay 600F (315℃).

3. Ang panguna nga brand o klase sa sugo

ASTM A333-Grade1、Grade4、Grade6、Grade7、Grade9、Grade10

ASTM A334-Grade1、Grade6、Grade7、Grade9

API 5CT80、L80-1、L803Cr、P110

4. Pamaagi sa pagsugbo sa produkto

GSTM 8333、 GSTM 8334、 API SPEC 5CT (9th)

5. Katangian sa produkto

Ang kompanya mao ang resistente sa low temperature ug dili may vascular, ang paggamit sa low sulfur ug low phosphorus nga high purity na bulig ug ang pagkalkulang pamaagi, makita niana ang madugangan ang low temperature brittleness sa bulig, ug mapadakel ang impact toughness sa mga produkto. Ang kompanya may 0 "-100C cooling tank, nga makahimo og low temperature impact test sa mosunod og mosunod aron maingon ang kalidad ug kabiliban sa mga produkto.

6. Gamitonan sa produkto

Ang mga cryogenic tube nga A333 ug A334 ay gamit alang sa mga pipe sa lele vessel grade -45-195C ug sa mga pipe sa cryogenic heat exchanger. Mahimo usab nila gamiton alang sa mga pipe sa paghatag og fluid sa mga kalibutan nga maonggamay init. Ang API5CT low-temperature resistant casing kay palig-on gamiton alang sa pagdril ng Wells sa mga dapit nga ekstrimadong lamaw. Mahimo gamiton ang tubo sa steel sa ekstrimadong maonggamay temperatura, apan adunay usab high strength, resistance sa korosyon, kaliwat nga proseso ug mabuting kabilidad sa pagsulod. Ang mga katagusan niini nagahatag sa A333GR.6 low temperature steel pipe nga mahimong madala gamiton sa mga industriya sa langis, natural gas, kimika ug uban pa.

7. Alang sa sakop sa produkto

Gwapong dyametro: 16mm~323.9mm; Lungsod sa wall: 2.0mm~40.0mm

Mga Applikasyon:

Kadaghanan gihapon gamiton sa petrokimiko, natural gas, kimiko, elektrisidad, pagsugnod ug uban pa nga mga bidang. Adunay kadaghanan kaubang og maayong pagbalhin, Sa langis, transmisyong pipa sa natural gas, petrokimikong kagamitan, pipa sa aircon sistema, cooler, generator sa buhaw, apan maogipon usab sa proseso sa mekanikal, pressure vessels, pagbuhat sa boiler, bulig nga structure sa tulog, dako nga mga dapit, exhibition centers, lifting machinery, balay sa baraha, dekorasyon, transportasyon na mga kagamitan, pagbuhat sa airport, bridge support, mine support, three-dimensional garage, outdoor advertising, fitness equipment, Pagbuhat sa bisikleta ug iban pa nga mga industriya

Especificasyon:

Standards sa seamless steel pipe

| API SPEC 5L | |||

| Ngalan sa Produkto | Ehekutibo nga Standard | Dimensyon (mm) | Steel Code / Steel Grade |

| Line Pipes | API 5L | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| Ngalan sa Produkto | Ehekutibo nga Standard | Dimensyon (mm) | Steel Code / Steel Grade |

| Kasing | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubing | API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM\/ASME | |||

| Ngalan sa Produkto | Ehekutibo nga Standard | Dimensyon (mm) | Steel Code / Steel Grade |

| Mga Tubo sa Takilya nga Wala'y Siklon nga mga Pipa sa Pilak (Black and Hot-Dipped Zinc-Coated) | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Mga Seamless Carbon Steel Tubo alang sa Serbisyo sa Mataas na Impra | ASTM A106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Mga Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger ug Condenser Tubo | ASTM A179 | ø10.3~426x WT1.0~36 | Low Carbon Steel |

| Mga Seamless Carbon Steel Boiler Tubo alang sa Mataas na Presyon | ASTM A192 | ø10.3~426 x WT1.0~36 | Low Carbon Steel |

| Wala'y sikat nga Gitawag sa Ulan Alupakong Tubo sa Kalibotan nga Steel Heat-Exchanger ug Condenser Tubes | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Wala'y sikat nga Katamtaman nga Carbon Steel Boiler ug Superheater Tubes | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Wala'y sikat nga Ferritic & Austenitic Alupakong Steel Boiler, Superheater & Heat-Exchanger Tubes | ASTM A213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Wala'y sugatong kabugtasan ug alloy na tubo alang sa mekanikal nga gamit | ASTM A333 | ø1\/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Wala'y sugatong ug nagsusulod nga tubo sa kabugtasan ug alloy para sa gamit sa maong temperatura | ASTM A334 | ø1\/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Tubong Seamless Cold-Drawn Carbon Steel Feedwater Heater | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Ngalan sa Produkto | Ehekutibo nga Standard | Dimensyon (mm) | Steel Code / Steel Grade |

| Tubong Seamless Steel alang sa Mataas na Imprastratura | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Tubong Seamless Steel | DIN 1629 \/ DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Tubong Seamless Steel | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Tubong Buhid nga Bulakngon alang sa Estructura | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| Ngalan sa Produkto | Ehekutibo nga Standard | Dimensyon (mm) | Steel Code / Steel Grade |

| Tubong Buhay nga Walang Gapa alang sa Estructura sa Makina | BS 970 | ø10~762x WT1.0~120 | Carbon Steel |

| Tubong Buhay nga Walang Gapa alang sa Boiler ug Heat Exchangers | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Kompetitibong Adunanan:

1. Maingon nga timbang.

Ang parameter mao ang 1/5 sa kwadrado nga bakal, kaya mas maayo ang iyang pagpapakita sa timbang ug lihis, mas lihis pa sa kwadrado nga bakal, ug ang iyang timbang mao man ang 1/5 lang sa kwadrado nga bakal.

2. Resistensya sa korosyon ug mataas nga temperatura.

Nauban ang kaligdigon sa korosyon ug resistensya sa tuig nga init, mas dako pa kaysa sa kwadrado nga bakal, A333 resistensya sa asido, alkali, asin ug ambon nga kinaiyahan sa korosyon, resistensya sa init, mahusay nga resistensya sa pagtaboy ug paglubog, wala pangangailangan sa regular nga pagsugba, mahimong makabulig sa paggamit ngadto sa higit pa sa 15 tuig.

3, wala magdeform ug anti-static.

Nauban sa mahusay nga katangian nga anti-static, mas dako pa kaysa sa ordinaryong tubo nga bakal, ang seamless pipes nauban sa kamatuoran nga elastisidad, maibulan sa mekanikal nga kagamitan, walay memorya, walay deformidad, ug anti-static, nauban ang seamless pipes sa mahusay nga katangian nga mekanikal, madali ang pagproseso, etc.

Ang atong maayong grupo gustuhon maghulom sa imo!