| Lugar sa Ginbuhat: | Shandong, China |

| Brand Name: | Changshengda(CSD) |

| Model Number: | Q195/Q235/Q345 SS400 |

| Pagsusi: | API, CE, GS, ISO9001 |

| Minimum Order Quantity: | 20 tons |

| Presyo: | 545USD/TON-680USD/TON |

| Detalye sa Pakete: | 1.Standard Marine packing |

| 2.Ayon sa mga kinahanglan sa customer | |

| Port: | Shanghai, Tianjin, Qingdao ports, pwede nimong ipangita ang ubang mga port sa imong kinahanglan. |

| Panahon sa Paghatag: | 8-14 adlaw |

| Mga Tugnaw sa Paghimo: | L/C,T/T |

| Kadakuan sa Pagsubay: | 100000 tonelada/bulan |

| Material: | ERW:Q235, Q345, 20#, J55, X42~65, ug iba pa. |

| LASW:Q195,Q235,Q345B,X42,X52,X60,S355JRH,S355J0H,S355J2H ug iba pa |

Deskripsyon:

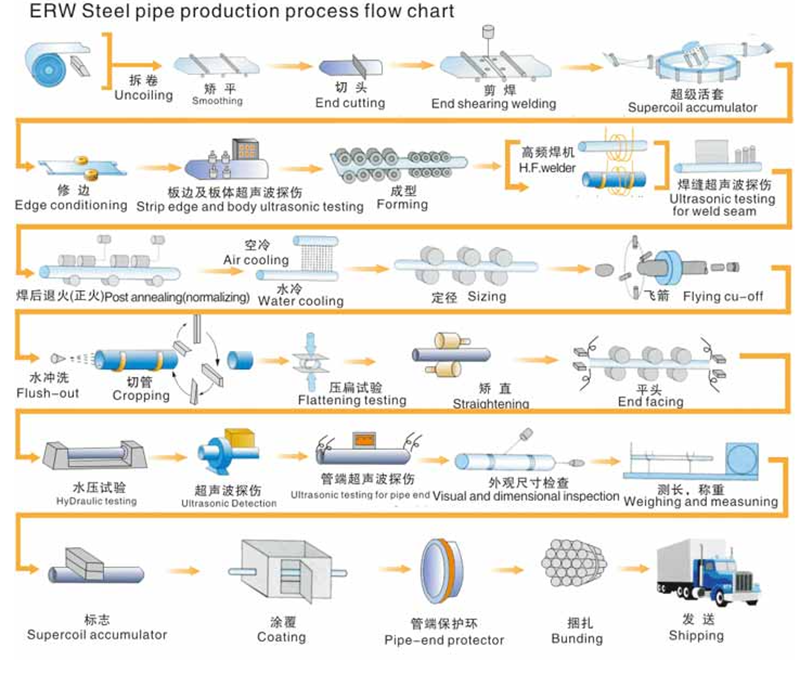

Ang straight seam high frequency (ERW) gitubag ha duha ka klase: induction welding og contact welding sunod sa lain-lain nga mga pamaagi sa pagtubag. Gigamit niini ang hot-rolled wide coils bilang materyales og nagdulom ha pre-bending, continuous forming, pagtubag, heat treatment, sizing, straightening, cutting, ug iba pa. Kumpara sa spiral process, adunay mga butangon kung unsa man ang mas maayo sama sa mas gamay nga mga taknaan sa pagtubag, mataas nga dimensional accuracy, uniform wall thickness, mahusay nga surface quality, og mataas nga pressure resistance. Apan ang kasabot niining klase mao ang dili mahimo niini magproducce og mga thin-walled pipes alang sa gamay og katamtaman nga diameter, og madaliso magbulag ha mga gray spots og lack of fusion sa mga takdaan sa pagtubag, Groove corrosion defects. Sa ngadto, ang pinakasugod nga field mao ang city gas, crude oil og refined oil transportation, ug iba pa.

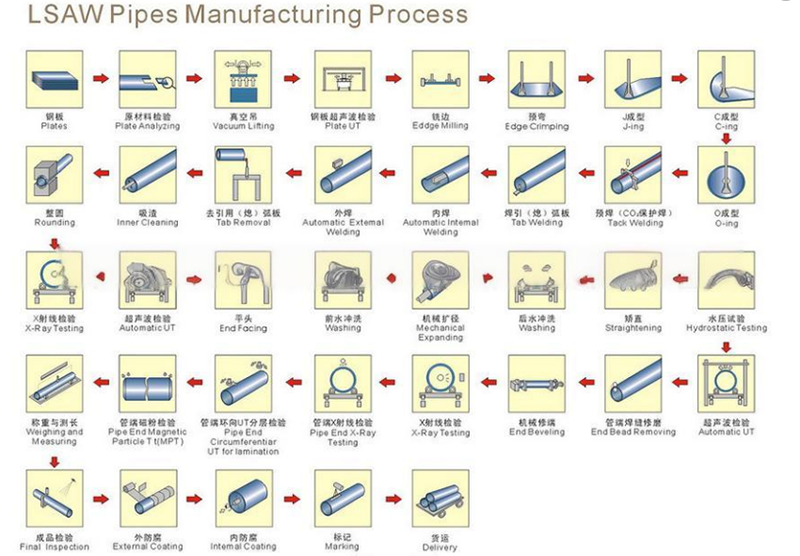

Ang straight seam submerged arc (LSAW) gitukod pinaagi sa paggamit og usa ka medium-thick plate bilang materyales, panghimasok (rolling) sa steel plate sa usa ka mold o forming machine, og paggamit og double-sided submerged arc welding og diameter expansion. Ang rango sa mga produktong gibulig niini kay lapad, ang katapusan, plastisidad, uniformidad, og densidad sa weld mao'y duol, ug adunay mga butangon sa daku nga tubo diametro, makatabang nga tubo wall, mataas nga presyo resistance, kalawtan resistance, og makapukaw nga korosyon resistance. Sa pagbuhat og mataas nga kalamboan, mataas nga katapusan, og mataas nga kalidad nga long-distance oil og gas pipelines, daghan sa kinahanglan nga mga steel pipes mao ang dakung diametro, makatabang nga straight seam submerged arc pipes. Sama sa API standards, sa dakung mga oil og gas transmission pipelines, ang straight-joint submerged arc mao ang usa ka tungod nga maoy gi-designate nga pipa tipo kun wala'y pasilod sa klase 1 og klase 2 areas sama sa alpine zones, sa dagat, og sa densely populated urban areas.

Sugod sa mga lain-lain nga pamamaraan sa pag-mold, mahibaw siya ngadto:

UOE tubo: Palibot sa usa ka singko nga plato ang i-pre-bend sa ilimlim, kini nagduruyan og proseso sama sa U porma, O porma, panulod sa sulod, panulod sa gawas, ug mekanikal nga malamig nga ekspansi.

JCOE tubo: kini usab, pre-panulod, porma, ug malamig nga ekspansi matapos ang panulod ayon sa "J-C-O-E"

HME tubo: porma niadtong mandril rolling method ayon sa "C-C-O", panulod kini og sunod malamig nga ekspansi.

Espesipikasyon:

| ERW TUBO | |

| ASTM | ASTM A53 B, ASTM A178, ASTM A252 GR.2, A500, ASTM A513 |

| EN | EN 10204/10217 S235JR,S275JR,S355,S355JR,S355J2H |

| API | API 5L X42\/46\/52\/56\/60\/70 |

| Carbon Steel | ASTM A671, ASTM A672 |

| Tanso sa Alloy | ASTM A691 |

| OD | 1\/2" -24" (21.3mm-610mm) |

| WT | 1.65mm-20mm |

| Paggamit | Line Pipe ; OCTG (Oil Country Tubular Goods); Round Structural Pipe; Coating Pipe. |

| LSAW PIPE | |||

| Padron | ASTM 53 ;API Spec 5L;ASTM A252-89; EN10217, EN10219 | ||

| Mga klase sa bakal | API 5L: GR A, GR B, X42, X46, X56, X60, X65, X70ASTM A252 GR 1, GR 2, GR 3ASTM A53: GR A, GR B, GR C, GR DBS 4360: Grade 43, Grade 50EN: S275, S275JR, S355JRH, S355J2H |

||

| Paggamit | Ginamit alang sa langis/gas/tubig; Pagtransmit; Inhinyering; Mga proyekto sa offshore. | ||

| Paggamit | OD(mm) | Timbang sa tabok (mm) | HABOG (m) |

| Roller pipe | 1200-3800(47.24”-150”) | 12-120 (1⁄2”- 4.7”) | <=3.2 |

| sa pagbuhat (Pipe Piles) | 350-1600(14”- 63”) | 6-60 (1⁄4” -2.36”) | 6-12 |

| Oli at gas pipeline | 406-1524(16”- 60”) | 6-40 (1⁄4”-1.57”) | 8-12.1 |

| Pagdugang sa usa ka higayonan, mahimong iprodyus ang mga pipa sumban sa kinahanglan sa kliyente. | |||

Lingkon nga Detalye:

Deskripsyon:

Mga pipa sa pilak na may straight seam nga gihimo sa tubig para sa mababaw nga presyon

Diameter: 219mm~508mm

Lubag: 6mm~20mm

Standard: GB/T 3091-2008

Material: L245~L690, Q235, ug iba pa.

Paggamit: Mahimong gamiton alang sa mga pipa nga gisuweld sa straight seam nga gamiton sa paghatag sa mababaw nga presyon nga mga likido tulog tubig, gas, hangin, ug heating steam ug uban pang mga estraktura.

American standard straight seam welded steel pipe

Diameter: 219mm~406mm

Lubag: 6mm~14mm

Standard: ASTM

Material: GrA GrB

Mga aplikasyon: Ginamit usa ka dagan sa mga proyekto sa pamamahala sa tubig, industriya sa langis ug gas, industriya sa kimika, industriya sa elektrisidad, agraryo nga irrigation, urbanong konstruksyon, ug iba pa.

Mga straight seam tulakang pipa alang sa oil casing ug oil pipes

Diameter 219mm~508mm

Tabing 6mm~20mm

Standard API-5CT

Material H40, J55, N80, P110

Aplikasyon: Oil casing ug tubing.

Amerikanong standard spiral welded tulakang pipa

Diameter 219mm~3520mm

Tabing pader 5mm~26mm

Standard ASTM

Material Gr.A, Gr.B, Gr.C, Gr.1~Gr.11

Gamit: Palakipan sa mga pile pipes alang sa mga proyekto sa pamihala sa tubig, industriya sa langis ug gas, kimika, elektrisidad, agrikultura nga pagtubig, urbanong konstruksyon, ug iba pa.

Straight seam pipeline tubo para sa transportasyon sa langis ug gas

Diameter 219mm~508mm

Tabing 6mm~20mm

Standard API-5L

Material Gr.B, X42~X100

Gamit: Ginamit para sa transportasyon sa langis ug natural na gas.

Kompetitibong Adunanan:

Ang kompanya nagsulod og teknolohiya ug makina nga internasyonal na advanced: tulad sa W-FF molding, solid-state high-frequency induction welding, ultrasonic flaw detection, magnetic flux leakage detection, ug high-end testing instruments: tulad sa metallographic analysis, Vickers hardness tester, impact testing machine, spectrometer Analyzers, universal testing machines ug iba pa nga mga makina. samtang gi-establish, nahimong molingaw sa mga internasyonal na sertipikasyon ug honorable qualifications: tulad sa API 5L, API5CT, ISO9002-2000 presyo pipeline production license, industrial product production license, China Petroleum and Petrochemical Membership Certificate, China Quality Product Certificate, ug uban pa. Ang produkto nag-export sa Timog Amerika, Hilagang Amerika, European Union, Southeast Asia ug iba pa. Natawo na kini sa pagsusulay sa mga customer sa tanang sulod sa mundo sa daghang tuig.

Ang atong maayong grupo gustuhon maghulom sa imo!