| Herkunftsort: | Shandong, China |

| Markenname: | Changshengda(CSD) |

| Artikelnummer: | Q195/Q235/Q345 SS400 |

| Zertifizierung: | API, CE, GS, ISO9001 |

| Mindestbestellmenge: | 20 Tonnen |

| Preis: | 545USD/TON-680USD/TON |

| Verpackungsdetails: | 1.Standard Marine Verpackung |

| 2.Nach Kundenanforderungen | |

| Hafen: | Shanghai, Tianjin, Qingdao Häfen, Sie können je nach Bedarf andere Häfen angeben. |

| Lieferzeit: | 8-14 Tage |

| Zahlungsbedingungen: | L/C, T/T |

| Lieferfähigkeit: | 100000 Tonnen/Monat |

| Material: | ERW: Q235, Q345, 20#, J55, X42~65 usw. |

| LASW: Q195, Q235, Q345B, X42, X52, X60, S355JRH, S355J0H, S355J2H usw. |

Beschreibung:

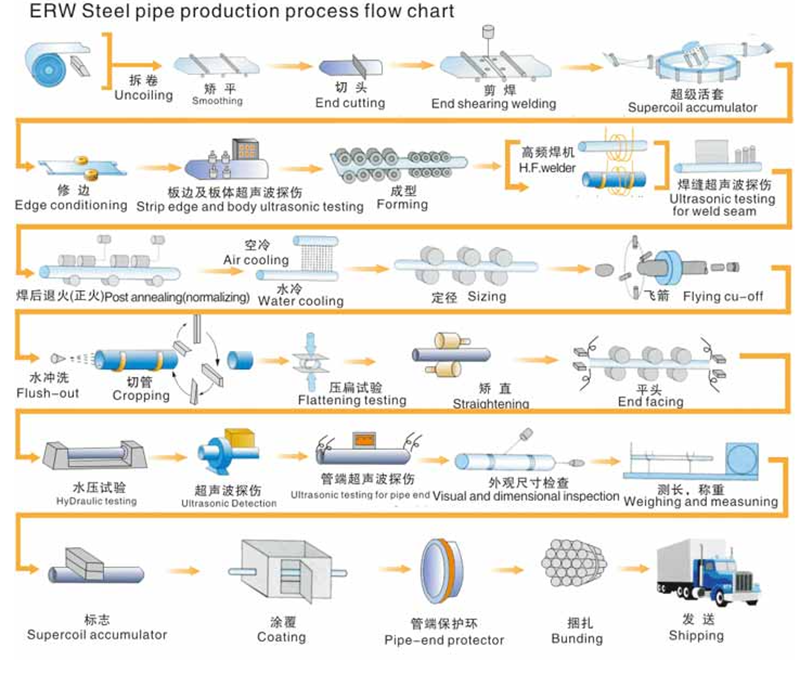

Gerader Naht Hochfrequenz (ERW) wird in zwei Formen unterteilt: Induktions- und Kontaktschweißen, je nach Schweißverfahren. Es verwendet heiße Breitrollen als Rohmaterial und durchläuft Vorbiegen, kontinuierliches Formen, Schweißen, Wärmebehandlung, Maßanpassung, Geradebiegen, Schneiden usw. Im Vergleich zum Spiralverfahren hat es die Vorteile kürzerer Nahte, hoher Maßgenauigkeit, gleichmäßiger Wandstärke, guter Oberflächenqualität und hoher Druckfestigkeit. Der Nachteil ist jedoch, dass nur dünnwandige Rohre mit kleinen und mittleren Durchmessern hergestellt werden können und an den Nahtstellen Grauflecken und Fehlfusionen auftreten können, sowie Risskorrosionsdefekte. Derzeit werden sie in den breitesten Bereichen wie Stadtgas, Rohöl- und Raffinieröltransport eingesetzt.

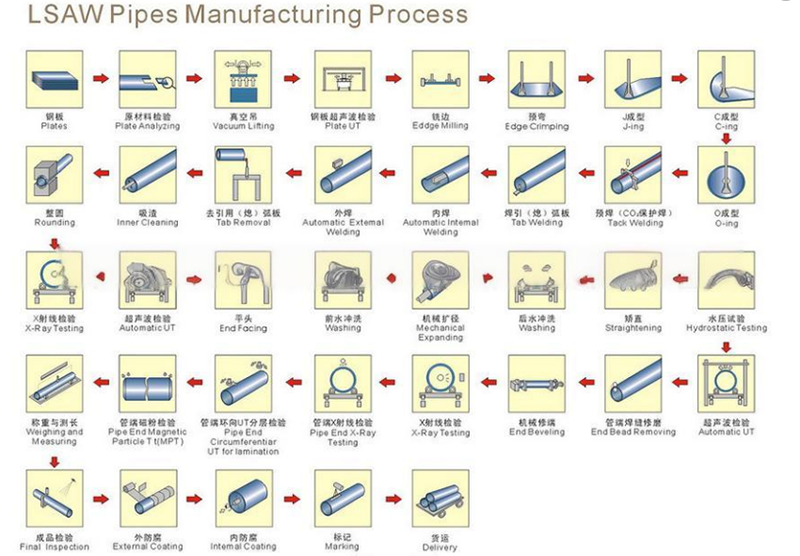

Der geradlinige Nahtunterbogenschweißverfahren (LSAW) wird hergestellt, indem eine einzelne Mittelstahlplatte als Rohmaterial verwendet wird, die Stahlplatte in einem Formwerkzeug oder einer Formmaschine gepresst (gewalzt) wird und dann mit doppelseitigem Unterbogenschweißen und Durchmessererweiterung versehen wird. Das Produktspektrum der Endprodukte ist breit, die Zähigkeit, Plastizität, Gleichmäßigkeit und Dichte des Schweissnahtes sind gut, und es bietet die Vorteile eines großen Rohrdurchmessers, einer dicken Rohrwand, hoher Druckwiderstandsfähigkeit, Kältebeständigkeit und starker Korrosionsbeständigkeit. Beim Bau von hochfesten, hochzähen und hochwertigen langstreckigen Öl- und Gasleitungen sind die meisten benötigten Stahlrohre große-durchmessige, dickwandige geradlinige Nahtunterbogenschweißrohre. Gemäß API-Normen ist bei großen Öl- und Gasübertragungsleitungen das geradlinige Naftunterbogenschweißrohr der einzige spezifisch vorgesehene Rohrtyp, wenn durch Gebiete der Klassen 1 und 2 wie Hochgebirge, Seeboden und stark besiedelte Stadtgebiete geführt wird.

Je nach verschiedenen Formverfahren kann es wie folgt unterteilt werden:

UOE Stahlrohr: Nachdem die einzelne Stahlplatte am Rand vorgebogen wurde, durchläuft sie Prozesse wie U-Formung, O-Formung, Innen-Schweißen, Außen-Schweißen und maschinelles kaltes Ausdehnen.

JCOE Stahlrohr: das heißt, vor dem Schweißen, Formen und kaltem Ausdehnen gemäß "J-C-O-E"

HME Stahlrohr: durch Kernwalzverfahren gemäß "C-C-O" geformt, geschweißt und dann kalt ausgedehnt.

Spezifikationen:

| Erw-Rohr | |

| ASTM | ASTM A53 B, ASTM A178, ASTM A252 GR.2, A500, ASTM A513 |

| EN | EN 10204/10217 S235JR,S275JR,S355,S355JR,S355J2H |

| API | API 5L X42/46/52/56/60/70 |

| Kohlenstoffstahl | ASTM A671,ASTM A672 |

| Legierter Stahl | ASTM A691 |

| OD | 1/2" - 24" (21,3 mm - 610 mm) |

| Wt | 1,65 mm - 20 mm |

| Anwendung | Leitungsrohr; OCTG (Ölbohrrohr); Rundes Tragrohr; Beschichtungsrohr. |

| LSaw-Rohr | |||

| Standard | ASTM 53; API Spec 5L; ASTM A252-89; EN10217, EN10219 | ||

| Stahlqualitäten | API 5L: GR A, GR B, X42, X46, X56, X60, X65, X70; ASTM A252 GR 1, GR 2, GR 3; ASTM A53: GR A, GR B, GR C, GR D; BS 4360: Typ; EN: S275, S275JR, S355JRH, S355J2H 43, Typ 50 |

||

| Anwendung | Verwendet für Öl/Gas/Wasser; Übertragung; Ingenieurwesen; Offshore-Projekte. | ||

| Anwendung | Außendurchmesser (mm) | WT(mm) | Länge (m) |

| Roller Rohr | 1200-3800(47.24”-150”) | 12-120 (1/2”- 4,7”) | <=3.2 |

| für den Bau (Rohrbeläge) | 350-1600 ((14- 63) | 6 bis 60 (1/4 -2,36) | 6-12 |

| Öl- und Gaspipeline | 406-1524 ((16- 60) | 6-40 (1/4-1.57) | 8-12.1 |

| Zusätzlich zu den vorstehenden Spezifikationen können die Rohre nach Kundenanforderungen hergestellt werden. | |||

Schnelle Einzelheiten:

Beschreibung:

Rohr aus Stahl mit geringer Druckflut

Durchmesser: 219 mm bis 508 mm

Wandstärke: 6 mm bis 20 mm

Norm: GB/T 3091-2008

Material: L245~L690, Q235, etc.

Anwendungen: Geeignet für geradnahtige geschweißte Stahlrohre, die bei der Transportierung von Niedrigdruckflüssigkeiten wie Wasser, Gas, Luft und Heißdampf sowie andere Strukturen verwendet werden.

Amerikanische Norm geradnahtiger geschweißter Stahlrohr

Durchmesser: 219mm~406mm

Wandstärke: 6mm~14mm

Norm: ASTM

Material: GrA GrB

Anwendungen: Hauptsächlich in Wasserbauprojekten, Öl- und Gasindustrie, Chemieindustrie, Elektrizitätsindustrie, Landwirtschaftsbewässerung, Stadtentwicklung usw. eingesetzt.

Geradnahtige Stahlrohre für Ölschutzrohre und Ölleitungen

Durchmesser 219mm~508mm

Wandstärke 6mm~20mm

Standard API-5CT

Material H40, J55, N80, P110

Anwendung: Ölzubehör und -leitungen.

Amerikanischer Standard spiralförmig geschweisster Stahlrohr

Durchmesser 219mm~3520mm

Wandstärke 5mm~26mm

Standard ASTM

Material Gr.A, Gr.B, Gr.C, Gr.1~Gr.11

Anwendung: Hauptsächlich in Pfahlrohren für Wasserbauvorhaben, Öl- und Gasindustrie, Chemieindustrie, Elektrizitätsindustrie, landwirtschaftliche Bewässerung, Stadtentwicklung usw. eingesetzt.

Gerade Nahtrohrstähle für den Transport von Öl und Gas

Durchmesser 219mm~508mm

Wandstärke 6mm~20mm

Standard API-5L

Material Gr.B, X42~X100

Anwendung: Für den Transport von Öl und Erdgas verwendet.

Wettbewerbsvorteil:

Das Unternehmen hat international fortgeschrittene Technologie und Ausrüstung ausgewählt: wie W-FF Formgebung, festflüssigen Hochfrequenzinduktions-Schweißanlagen, Ultraschall-Flaw-Detection, Magnetfluß-Ausfall-Detektion und hochwertige Prüfinstrumente: wie metallurgische Analyse, Vickers-Härteprüfgerät, Schlagprüfmaschine, Spektrometer-Analysatoren, universelle Prüfmaschinen und andere Geräte. Seit seiner Gründung hat es verschiedene internationale Zertifikate und ehrenwerte Qualifikationen erhalten: wie API 5L, API5CT, ISO9002-2000 Druckrohrleitungs-Fertigungslizenz, Industrie-Produktionslizenz, Mitgliedszertifikat der China Petroleum and Petrochemical Corporation, China-Qualitätsprodukt-Zertifikat usw. Die Produkte werden nach Südamerika, Nordamerika, die Europäische Union, Südostasien und andere Orte exportiert. Sie werden seit vielen Jahren von Kunden auf der ganzen Welt gut aufgenommen.

Unser freundliches Team freut sich auf Ihre Nachricht!