| Herkunftsort: | Shandong, China |

| Markenname: | $560-600/TON |

| Artikelnummer: | A106/A53GRB API5L/Q195,Q235,Q275,Q355,Q345,SAE1010/1020,1045,etc |

| Zertifizierung: | API, CE, Bsi, RoHS, SNI, BIS, tisi, KS, JIS, GS, ISO9001 |

| Mindestbestellmenge: | 1 Tonne |

| Preis: | $560/TONNE |

| Verpackungsdetails: | Exportverpackungsstandard (In Bündeln, Nylontaschen, Holzkisten oder nach Bedarf) |

| Lieferzeit: | 3-7 Tage |

| Zahlungsbedingungen: | FOB 30% Vorauszahlung, 70% vor der Lieferung |

| CIF 30% Anzahlung und das Restbetrag ist vor der Verschiffung zu zahlen | |

| oder Irrevokables 100% L/C auf Erstpräsentation | |

| Lieferfähigkeit: | 10000 Tonnen pro Monat |

Beschreibung:

Galvanisierte Stahlrohre werden in warmgalvanisierte Stahlrohre und kaltgalvanisierte Stahlrohre unterteilt

Thermisch galvanisierte Rohre

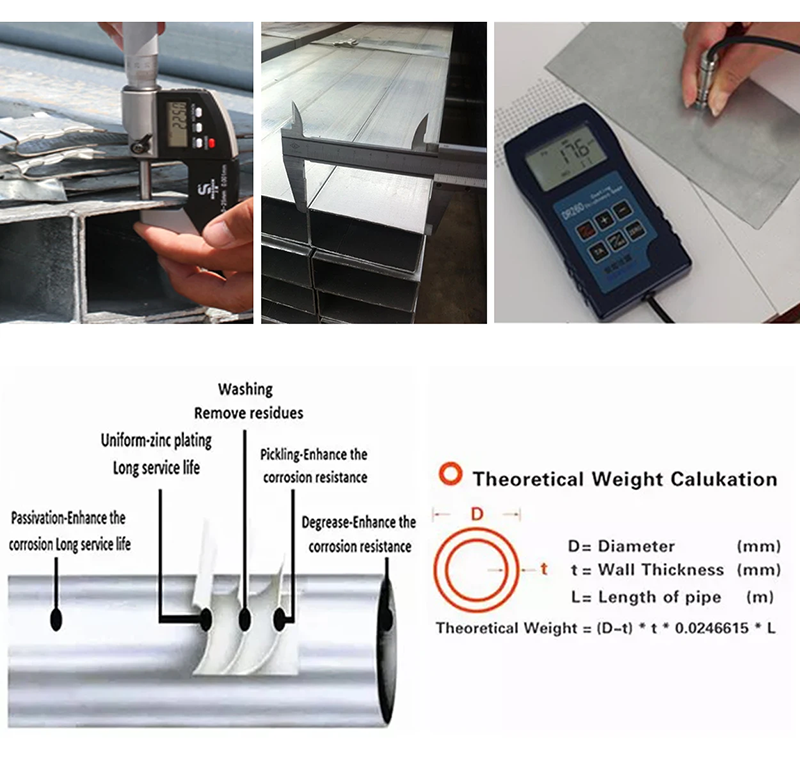

Das flüssige Metall reagiert mit einer Eisenmatrix, um eine Legierungsschicht zu erzeugen, wodurch Basis und Belagschicht verbunden werden. Warmgalvanisieren bedeutet zunächst das Einlegen des Stahlrohrs, um die Eisenoxyde auf der Oberfläche des Stahlrohrs zu entfernen. Nach dem Einlegen wird es mit einer Ammoniumchlorid- oder Zinkchlorid-Wässerlösung oder einer gemischten Wässerlösung aus Ammoniumchlorid und Zinkchlorid gewaschen und dann in den Warmtauchzinkbade-Tank geführt. Warmtauchgalvanisieren hat die Vorteile einer gleichmäßigen Beschichtung, starker Haftfestigkeit und langer Lebensdauer. Die meisten Verfahren im Norden verwenden galvanisierte Streifen, um das Zink direkt zu walzen.

Kalt galvanisierte Röhre

Kaltgalvanisieren ist Elektrogalvanisieren. Die Menge an Galvanisierung ist sehr gering, nur 10-50g/m², und ihre Korrosionsbeständigkeit ist viel schlechter als die von hochglasierten Röhren. Reguläre Hersteller von galvanisierten Rohren gewährleisten die Qualität, indem sie in der Regel kein Elektrogalvanisieren (Kaltes Beschichten) verwenden. Nur kleine Unternehmen mit kleinem und veraltetem Equipment verwenden elektrogalvanisierte Stahlrohre, natürlich sind deren Preise relativ günstiger. In neu gebauten Häusern ist die Verwendung von kalten galvanisierten Stahlrohren als Wasserversorgungsrohre verboten.

Unterschied zwischen Hochglasierung und Kaltgalvanisierung

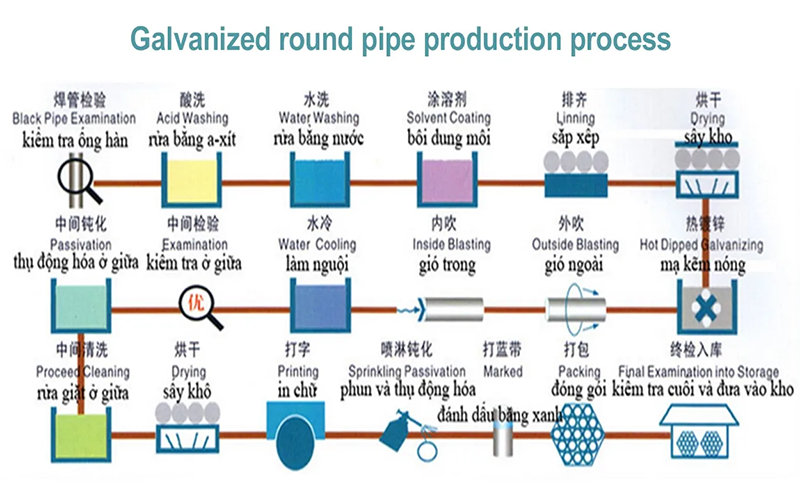

Hochglasiertes Verfahren:

Teil entfetten → waschen → ätzen → waschen → trocknen → Lösemittelbad flussieren vorheizen hochglasiert galvanisieren → abkühlen → nachbearbeiten → spülen → trocknen → Passivierungstest

Kaltgalvanisierungsverfahren:

Chemische Entfettung → Waschen → Warmwasser Elektrolyse-Entfettung → Waschen → Waschen → Stark korrosiver Galvanisierter Eisenlegierung → Waschen → Waschen → Leicht → → Waschen → Trocknen Passivierung

Vorteile von galvanisierten Rohren sind die folgenden:

Erstens kann die Oberfläche eines galvanisierten Rohres nach dem heißen Zinkbad geschützt werden, und innen im Hohlraum des Rohres oder an Ecken, wo andere Beschichtungen schwer zugänglich sind, kann das Zink leicht bis zum Gipfel reichen und so das gesamte galvanisierte Rohr schützen.

Zweitens, nachdem das Galvanisierungsrohr galvanisiert wurde, sind seine Widerstandsfähigkeit und Verschleißfestigkeit sehr gut, da der Zinkschicht-Härte-Wert größer als die Härte von Stahl ist. Daher ist der Widerstand gegen Stoß und Verschleiß nach dem Hot-Dip-Galvanisieren ziemlich gut. Darüber hinaus ist der größte Vorteil der Galvanisierung, dass die Zinkschicht in den Ecken relativ dick ist und eine gute Zähigkeit und Verschleißfestigkeit aufweist, während andere Beschichtungen oft in diesen Ecken am dünnsten und am schwierigsten zu konstruieren sind und daher anfällig für Schäden sind.

Spezifikationen:

| l Beschreibung | l Galvanisierte Schweissröhre | |

| l Stahlqualität | l Astm a53 Gr.B / ASTM A106 | |

| l Norm | l ASTM A106/A106M;ASTM A53/A53M;API 5L;GB/T 8163-2008;GB/T 8162-2008;BS1387, BS1139,EN39, EN1139, ASTM A53, JIS G3444 | |

| l Material | l A106 Klasse A, A106 Klasse B, A106 Klasse C, A53 Klasse A, A53 Klasse B, API 5L Klasse B, 10#, 20#, 45# | |

| l Oberfläche | l Hot-Dip-Galvanisierung; Elektrogalvanisierung; Auf Wunsch des Kunden | |

| l Typ | l 1. Vorangestrichen (Zink: 60-120G/M2) l 2. Hochglanzgalvanisiert (Zink: 120-500G/M2) l 3. Kaltgalvanisiert (Zink: 10-50G/M2) | |

| l Größe | l Wandstärke | l 1-22mm |

| Außendurchmesser | 21,3mm-610mm | |

| l Lieferzeit | l Sofortige Lieferung oder je nach Bestellmenge. | |

| l Verpackung | l Standardexportverpackung, schiffstauglich, oder auf Wunsch. | |

| l Anwendung | l Flüssigkeitsförderung; tragende Strukturen; HVAC; Öl- und Gasindustrie; industrielle Ausrüstung | |

| l Kontakt | l Wenn Sie Fragen haben, zögern Sie nicht, mich zu kontaktieren. | |

| l Containergröße | l 20ft GP: 5898mm (Länge) x 2352mm (Breite) x 2393mm (Höhe) 24-26CBMl l 40ft GP: 12032mm (Länge) x 2352mm (Breite) x 2393mm (Höhe) 54CBMl l 40ft HC: 12032mm (Länge) x 2352mm (Breite) x 2698mm (Höhe) 68CBM |

|

Schnelle Einzelheiten:

1. gi Rohr, Hot Dip Galvanisiertes Rundstahlrohr, Galvanisiertes Stahlrohr Galvanisierter Rohr, geschweißtes gi Stahlrohr, gi Stahlrohr

2. Hot-dip-galvanisiertes Stahlrundrohr (HDG) wird weltweit in verschiedenen Industrien und im Bauwesen eingesetzt.

Kaltgalvanisierte Rohre werden elektrisch galvanisiert, die Galvanisierungsmenge ist sehr gering, nur 10-50g/m2, ihre Korrosionsbeständigkeit unterscheidet sich stark von der von hot-galvanisierten Rohren.

Es kann in der Baubranche, Maschinenbau, Kohlebergbau, Chemieindustrie, Elektrizitätswerken, Schienenfahrzeugen, Automobilindustrie, Straßenbau, Brückenbau, Containern, Sportanlagen, Landmaschinen, Erdölmachinen, Erkundungsmaschinen und anderen Fertigungsbranchen eingesetzt werden.

| Chemische Eigenschaften % | |||||||||

| Klasse A | |||||||||

| C | Mn | P | S | Ja, das ist es. | Cr | Cu | Mo | Ni | V |

| 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Klasse B | |||||||||

| C | Mn | P | S | Ja, das ist es. | Cr | Cu | Mo | Ni | V |

| 0.3 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Qualitätsstufe C | |||||||||

| C | Mn | P | S | Ja, das ist es. | Cr | Cu | Mo | Ni | V |

| 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Mechanische Eigenschaften | |||

| Klasse A | Klasse B | Qualitätsstufe C | |

| Zugfestigkeit | 330 | 415 | 485 |

| Fließgrenze | 205 | 240 | 275 |

Beschreibung:

Galvanisierte Schweissrohre bezeichnen eine Art Stahlrohr, das durch einen Prozess namens Galvanisierung mit einer Schicht Zink überzogen wurde.

Der Galvanisierungsprozess umfasst das Eintauchen des Stahlrohres in ein Bad flüssigen Zinks, wodurch sich eine schützende Schicht auf der Oberfläche des Rohres bildet.

Das Ziel der Galvanisierung von Schweissrohren ist es, Korrosionsbeständigkeit zu bieten und die Lebensdauer des Rohrs zu verlängern. Die Zinkschicht dient als Barriere zwischen dem Stahl und der Umgebung, um das Rohr vor Rost und anderen Formen von Korrosion zu schützen.

Dadurch sind galvanisierte Schweissrohre für verschiedene Anwendungen geeignet, insbesondere in Branchen, in denen eine Aussetzung mit Feuchtigkeit oder korrosiven Substanzen häufig ist.

Einige der wichtigsten Vorteile von verzinnten geschweißten Rohren umfassen:

1. Korrosionsbeständigkeit: Die Zinkschicht bietet eine hervorragende Korrosionsbeständigkeit, wodurch verzinnte Rohre für Außenanwendungen und unterirdische Installationen geeignet sind.

2. Haltbarkeit: Die Kombination aus Stahl und Zinkschicht erhöht die Stärke und Haltbarkeit des Rohres, sodass es

sich widrigen Bedingungen und intensiver Nutzung standhalten kann.

3. Kosteneffizienz: Verzinnte geschweißte Rohre sind im Allgemeinen günstiger als andere korrosionsbeständige Alternativen, was sie zu einer kosteneffektiven Wahl für verschiedene Projekte macht.

4. Einfache Installation: Verzinnte geschweißte Rohre lassen sich aufgrund ihrer standardisierten Größen und Kompatibilität

mit gebräuchlichen Anschluss- und Verbindungsteilen relativ einfach installieren.

5. Vielseitigkeit: Verzinnte geschweißte Rohre sind in verschiedenen Größen und Dicken verfügbar, was sie für eine breite Palette an Anwendungen einschließlich Sanitärinstallationen, Bauwesen, Landwirtschaft und Industrieprojekte geeignet macht.

Es ist wichtig zu beachten, dass galvanisierte geschweißte Röhren Einschränkungen haben. Im Laufe der Zeit kann die Zinkschicht abnutzen oder abfallen,

insbesondere in hochkorrosiven Umgebungen. Daher sind regelmäßige Inspektionen und Wartungsarbeiten notwendig, um den fortlaufenden Schutz der Röhre sicherzustellen.

Außerdem sollte bei der Arbeit mit galvanisierten geschweißten Röhren angemessene Sicherheitsvorkehrungen getroffen werden, wie zum Beispiel die Verwendung von

geeigneten Schutzausrüstungen und die Sicherstellung einer ordnungsgemäßen Belüftung, da beim Galvanisierungsprozess Dämpfe freigesetzt werden können, die schädlich sein können, wenn sie eingeatmet werden.

Anwendungen:

bauwesen, Maschinenbau, Kohlebergbau, Chemische Industrie, Elektrizität, Eisenbahnfahrzeuge, Automobilindustrie, Straße, Brücke, Container, Sportanlagen, Landmaschinen, Erdölmachinen, Erkundungsmaschinen und andere Fertigungsindustrien.

Spezifikationen:

| Galvanisierter Runder Stahlrohr | |||||||||

| Norm: API 5L, API 5CT, ASTM A53, ASTM A500, GB9711.1 Anwendung: Für den Transport von Gas, Wasser und Erdöl in der Öl- und Erdgasindustrie und verwenden für den Zweck der Stahlrohre Hauptstahlröhrenqualität: GR.A, GR.B, GR.C, Q195, Q235B, Q345B und so weiter. |

|||||||||

| Zoll | Außendurchmesser (mm) | Normale Wandstärke | |||||||

| SCH 10WT (mm) | SCH 20WT (mm) | SCH 40WT (mm) | SCH 60WT (mm) | SCH 80WT (mm) | SCH 100WT (mm) | SCH 160WT (mm) | XXS (mm) | ||

| 1 / 4 | 13.7 | 2.24 | 3.02 | ||||||

| 3/8" | 17.1 | 2.31 | 3.2 | ||||||

| 1/2 | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1 bis 4 Zoll. | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1⁄2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.5 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.7 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.7 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

| 30" | 762 | 7.92 | 12.7 | ||||||

| 32" | 813 | 7.92 | 12.7 | 17.48 | |||||

| 34" | 863 | 7.92 | 12.7 | 17.48 | |||||

| 36" | 914 | 7.92 | 12.7 | 19.05 | |||||

| 38" | 965 | ||||||||

| 40" | 1016 | ||||||||

| 42" | 1066 | ||||||||

| 44" | 1117 | ||||||||

| 46" | 1168 | ||||||||

| 48" | 1219 | ||||||||

Wettbewerbsvorteil:

Wir bieten wettbewerbsfähige Preise und pünktliche Liefervorteile bei der Lieferung von nahtlosen Stahlröhren, nicht nur für Großkunden, sondern wir akzeptieren auch Kundenaufträge für personalisierte Designs, Spezifikationen und Verpackungsanforderungen.

Unser freundliches Team freut sich auf Ihre Nachricht!