| Lokorigino: | Shandong, Ĉinio |

| Marknomo: | $560-600/TON |

| Modela nombro: | A106/A53GRB API5L/Q195,Q235,Q275,Q355,Q345,/SAE1010/1020,1045,ktp |

| Certigado: | API, CE, Bsi, RoHS, SNI, BIS, tisi, KS, JIS, GS, ISO9001 |

| Minimuma Ordona Kvantumo: | 1TON |

| Prezo: | $560/TON |

| Detaloj pri Embrakado: | Normo de ekspord-pakado (En pako, nilonaj sakoj, leĝna kazoj aŭ laŭ postuloj) |

| Tempo por Livrado: | 3-7tagoj |

| Kondiĉoj pri Pago: | FOB 30%T/T, 70% antaŭ ŝipo |

| CIF 30% antaŭpago kaj la restanta sumo devas esti pagita antaŭ ol fari ŝipon | |

| aŭ Neanuligebla 100% L/C je vido | |

| Cediga Povumo: | 10000 Tonelado/Toneladoj por Monato |

Priskribo:

Galfanita ĉelo tubo disdividigas en varm-galfanitan ĉelon tubon kaj malvarm-galfanitan ĉelon tubon

Varme cinkigita tubo

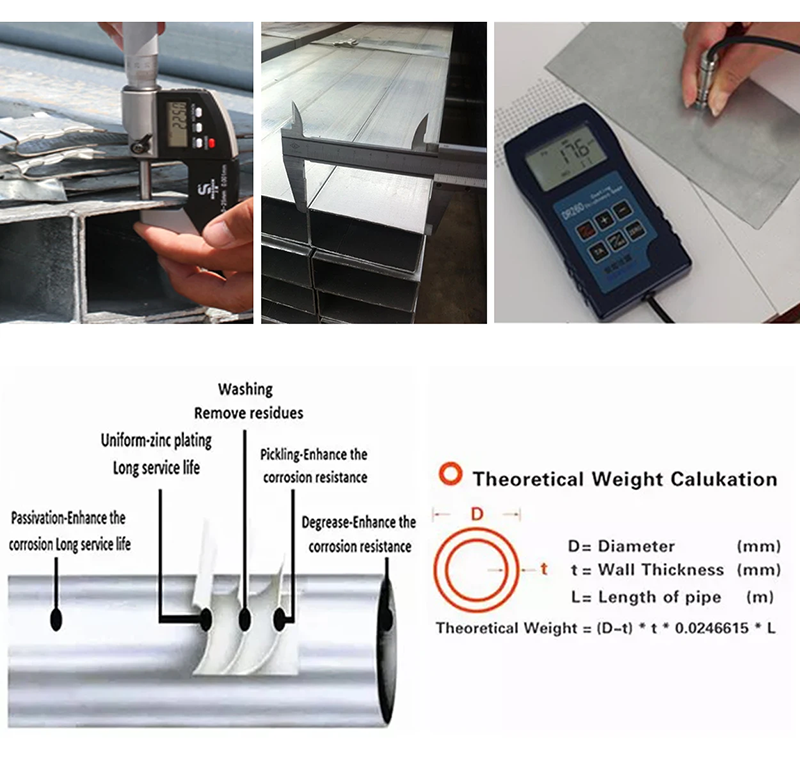

La fusa metalo reagas kun feraj matricoj por produkti ligon, tiel kunigante la substraton kaj la plaĝan layon. La termplaĝado estas unuaĵo pikli la ŝaftujon, por forigi la feran oksidon sur la surfaco de la ŝaftujon, post piklado, ĝi estas lavita per amonikla aŭ zinkkla akva solvo aŭ miksa akva solvo de amoniklo kaj zinkklo, kaj poste alportita. Termplaĝada tanko. La termplaĝado posedas la avantaĝojn de uniforma plaĝado, forta adhezo kaj longa serv vivo. Plej multe de la nordaj procezoj uzas galvanigitajn tajerojn direktan konvoluci al la cinko.

Froidcinkigita tubo

Froida galvanizado estas elektrogalvanizado. Kvantumo de galvanizado estas tre malgranda, nur 10-50g/m2, kaj ĝia korozia rezisto estas multe pli malbona ol tiu de varmegalvanizitaj tuboj. Regulaj galvanizitaj tubfabrikantoj, por certigi la kvaliton, plejparte ne uzas elektrogalvanizon (froidan plaĝon). Nura malgrandaj entreprenoj kun malgrandaj aparatoj kaj malnovaj aparatoj uzas elektrogalvanizitan acieron, nature, iliaj prezoj estas relative pli malĉeraj. En novkonstruitaj domoj, la uzo de froidgalvanizitaj akvotuboj kiel akvoconduitaj tuboj estas malpermesita.

Diferenco inter varmega galvanizado kaj froida galvanizado

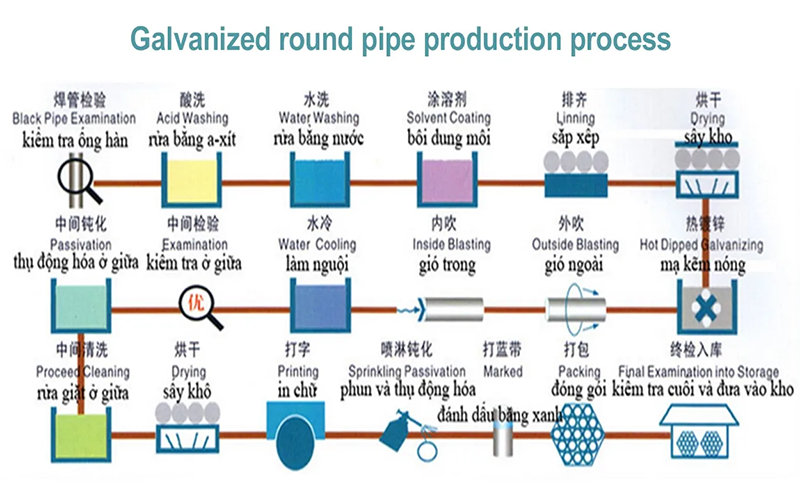

Procezo de varmega galvanizado:

Degrasado de laborpeco → lavado → piklado → lavado → sekigado solvanto → fluksado → prevarmigo → varmega galvanizado → rafreŝigo → finigaĵo → lavo → seko → pasivigo testo

Procezo de froida galvanizado:

Kemika degreasado → lavado → varma akva elektroliza degreasado → lavado → lavado → forta koroziva galvanizita feraj aliaj ligoj → lavado → lavado → leĝera → → lavado → sekado pasivigo

Avantagnoj de galvanizitaj tuboj estas la jenaj:

Unue, la surfaco de galvanizita tubo post varma dukto galvanizado povas esti protektita, kaj ene de la tubo aŭ iu alia kovrilo la angulo estas malfacila atingi, sed la cinko povas facile kovri ĝis la supro, tiam tuta galvanizita tubo povas esti protektita.

Dua, post esti galvanizita, la impaktrezistecon kaj antaŭŝurtezistancon de la tubo estas tre bona, ĉar la duro de la cinkumbrako estas pli alta ol la duro de la stalo, kaj tial la impaktrezisto kaj ŝurtespezistanco post varma cinkumado estas tre bona. Plie, la plej granda avantaĝo de cinkumado estas ke la cinkumbrako en la angulo estos relative pli dika kaj havos bonan flekseblecon kaj ŝurtespezistancon, dum aliaj ubraj estas ofte la plej malprofundaj kaj malfacilaj konstrui en tiuj anguloj, kaj tial ili estas vulneblaj al difektoj.

Specifiko:

| l Priskribo | l Cinkumita svarmega tubo | |

| l Staloklaso | l Astm a53 Gr.B / ASTM A106 | |

| l Normo | l ASTM A106/A106M;ASTM A53/A53M;API 5L;GB/T 8163-2008;GB/T 8162-2008;BS1387, BS1139,EN39, EN1139, ASTM A53, JIS G3444 | |

| l Materialo | l A106 Klaso A, A106 Klaso B, A106 Klaso C, A53 Klaso A, A53 Klaso B, API 5L Klaso B, 10#, 20#, 45# | |

| l Superficio | l Terma galvanizado; Elektra galvanizado; Metodo petita de la kliento | |

| l Tipo | l 1. Antaŭpintita (cinko: 60-120G/M2) l 2. Terme cinkita (cinko: 120-500G/M2) l 3. Freŝcinkita (cinko: 10-50G/M2) | |

| l Grandeco | l Muro epeseco | l 1-22mm |

| Ekstera diametro | 21.3mm-610mm | |

| l Liverigotempo | l Rapida liverigo aŭ kiel la komandkvanto. | |

| l Pakaĵo | l Norma eksporta maravigla pakaĵo, aŭ kiel postulata. | |

| aplikado | transpordado de fluoj; struktura subteno; HVAC; olaj kaj gazoj industrio; industriaj aparatoj | |

| kontakto | se vi havas iujn demandojn, bonvolu libere kontakti min. | |

| grandaĵo de konteiner | 20ft GP: 5898mm (Longeco) x 2352mm (Largeco) x 2393mm (Alteco) 24-26CBMl l 40ft GP: 12032mm (Longeco) x 2352mm (Largeco) x 2393mm (Alteco) 54CBMl l 40ft HC: 12032mm (Longeco) x 2352mm (Largeco) x 2698mm (Alteco) 68CBM |

|

Rapid Detalo:

1.gi tubo, Hot Dip Galvanized Round Steel Pipe, Galvanized Steel Pipe Galvanized Tube, sudaĝita gi acia tubo, gi acia tubo

2.Hot dipped galvanized steel round pipe (HDG), estas larĝe uzata en diversaj industrioj kaj konstruaĵoj ĉie en la mondo.

Froida galvanizita tubo estas elektra galvanizado, kie la kvanto de galvanizado estas tre malgranda, nur 10-50g/m2, kaj ĝia propra korodoresisteco estas multe malsama ol ĉe varma galvanizita tubo.

Ĝi povas esti uzita en konstruado, maŝinarijo, karbono minejo, kemia industrio, elektra energio, fervojaj vagonoj, aŭtomobil industrio, vojoj, pintoj, konteineroj, sportaj facilatoj, agricola maŝinarijo, petrolea maŝinarijo, esploranta maŝinarijo kaj aliaj fabrikadoj.

| Kemiaj trajtoj % | |||||||||

| Grado A | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Grado B | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.3 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Klaso C | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Meĥanikaj trajtoj | |||

| Grado A | Grado B | Klaso C | |

| Tensila Forto | 330 | 415 | 485 |

| Cedoforto | 205 | 240 | 275 |

Priskribo:

Galvanizita svarmiĝa tubo rilatas al speco de acia tubo, kiu estas kovrita per strato de cincumo tra procezo nomata galvanizado.

La galvanizproceso inkludas submerĝon de la acia tubo en bason da fusa cincumo, kiu formas protektan straton sur la surfaco de la tubo.

La celo de la galvanizado de svarmiĝaj tuboj estas provizi korozian resistemon kaj etendi la uzovivan longon de la tubo. La cincuma kovro agas kiel bariero inter la acero kaj la ĉirkaŭa medio, protektante la tubon kontraŭ ruĝado kaj aliaj formoj de korozo.

Tio igas galvanizitajn svarmiĝajn tubojn taŭgaj por diversaj aplikaĵoj, speciale en industrioj, kie ekzisto de umecteco aŭ korozivaj materialoj estas ofta.

Kelkaj el la plej gravaj avantaĝoj de galvanizitaj svarmiĝaj tuboj inkludas:

1. Korozia resistemo: La cincuma kovro provizas ekselan korozian resistemon, igante galvanizitajn tubojn taŭgaj por eksterlandaj kaj subterraj aplikaĵoj.

2. Daŭreco: La kombinaĵo de stalo kaj cinka revestro pliiĝigas la forton kaj daŭrecon de la tubo, permesante al ĝi

resisti malamikajn kondiĉojn kaj intensivan uzadon.

3. Kostefikeco: Cinkigitaj svarmaj tuboj estas ĝenerale pli afablaĵaj ol aliaj korozio-resistaj alternativoj, igant ilin kostefika elekto por diversaj projektoj.

4. Facila montado: Cinkigitaj svarmaj tuboj estas relative facilaj por instali pro iliaj normaligitaj grandecoj kaj kompatobleco

kun ofte uzataj fiksoelementoj kaj konektiloj.

5. Versateco: Cinkigitaj svarmaj tuboj estas haveblaj en diversaj grandecoj kaj spesmaloj, igant ilin taŭgaj por ampleksa gamo da aplikaĵoj, inkluzive de sano, konstruado, agraro kaj industriaĵoj.

Grave noti ke cinkigitaj svarmaj tuboj havas limigojn. Laŭtempene, la cinka revestro povas degeneri aŭ elportiĝi,

precipe en tre korozivaj medioj. Tial, regula kontrolado kaj entreteno estas necesa por certigi la daŭran protekton de la tubo.

Plie, dum laborado kun galvanizitaj svarmaj tuboj, estas grave preni taŭgajn sekurecajn mezurojn, kiel ekzemple uzo de

taŭga persona protektanta ekipamento kaj ensurado de bona ventilo, ĉar la galvanizado povas elpreni fumojn kiuj povus esti damaĝaj se enhalete.

Aplikoj:

konstruado,machinery, koalmino, kemia industrio, elektra energio, vojakaj vagonoj, aŭtomobil-industrio, autopovo, ponto, konteiner, sportaj facilatoj, agrara machinery, petrola machinery, eksplorada machinery kaj aliaj fabrikado-industrioj.

Specifiko:

| Galvanizita Ronda Stalo Tubo | |||||||||

| Normo:API 5L,API 5CT,ASTM A53,ASTM A500,GB9711.1 Uzo:Por esti uzata por transdoni gason, akvon,kaj petrolemon por olaj kaj natura-gasa industrioj kaj uzi por la struktura stala tubo celo Ĉefa Stala Tubo Grado:GR.A,GR.B,GR.C,Q195,Q235B,Q345B kaj tiel plu. |

|||||||||

| Colimo | EK (mm) | Norma Mura Malsekveco | |||||||

| SCH 10WT (mm) | SCH 20WT (mm) | SCH 40WT (mm) | SCH 60WT (mm) | SCH 80WT (mm) | SCH 100WT (mm) | SCH 160WT (mm) | XXS (mm) | ||

| 1⁄4” | 13.7 | 2.24 | 3.02 | ||||||

| 3⁄8” | 17.1 | 2.31 | 3.2 | ||||||

| 1⁄2” | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3⁄4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1⁄2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1⁄2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1⁄2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.5 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.7 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.7 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

| 30" | 762 | 7.92 | 12.7 | ||||||

| 32" | 813 | 7.92 | 12.7 | 17.48 | |||||

| 34" | 863 | 7.92 | 12.7 | 17.48 | |||||

| 36" | 914 | 7.92 | 12.7 | 19.05 | |||||

| 38" | 965 | ||||||||

| 40" | 1016 | ||||||||

| 42" | 1066 | ||||||||

| 44" | 1117 | ||||||||

| 46" | 1168 | ||||||||

| 48" | 1219 | ||||||||

Konkuraca Avantaĝo:

Ni ofertas konkurencige prezojn kaj tempeblajn liverumajn avantaĝojn en la distribuo de senĵonaj acieraj tuboj, ne nur por volumaj klientoj, sed ankaŭ akceptas klientajn komandojn por personigita dezajno, specifecoj kaj empaŝaj postuloj.

Nia amika teamo ŝatas aŭdi de vi!