| Lugar de Origen: | Shandong, China |

| Nombre de la Marca: | jinzheng |

| Número de Modelo: | 16MnDG, 10MnDG, 09DG, 09Mn2VDG, 06Ni3MoDG, ASTM A333-Grado1, Grado3, Grado4, Grado6, Grado7, Grado8, Grado9, Grado10, Grado11 |

| Certificación: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| Cantidad Mínima de Pedido: | 1 tonelada |

| Precio: | $650/ton |

| Detalles de Embalaje: | Estándar de Embalaje para Exportación (En paquetes de nailon, casos de madera o según lo requerido) |

| Tiempo de entrega: | 15-20días |

| Términos de Pago: | FOB 30% T/T, 70% antes del envío |

| CIF 30% pago anticipado y el saldo debe ser pagado antes de hacer el envío | |

| o Crédito Documentario Irrevocable al 100% a la vista | |

| Capacidad de Suministro: | 2000 Toneladas por Mes |

Detalle rápido:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,tubo sin costura,Tubo de Acero Alcalino y de Aleación Sin Costura para Aplicaciones Mecánicas

El tubo de acero para bajas temperaturas A333 se utiliza ampliamente en los campos del petroquímico, gas natural, química, electricidad, calefacción y otros. Su amplio rango de aplicaciones es flexible; se utiliza en oleoductos y gasoductos de transmisión de petróleo y gas natural, equipos petroquímicos, sistemas de tuberías de aire acondicionado, enfriadores, generadores de vapor, así como en el procesamiento mecánico, recipientes a presión, fabricación de calderas, estructuras de acero para edificios, grandes recintos, centros de exposiciones, maquinaria de elevación, construcción naval, estanterías de almacenamiento, decoración, instalaciones de transporte, construcción de aeropuertos, soportes de puentes, soporte minero, garajes automatizados, publicidad al aire libre, equipos de fitness y fabricación de vehículos, entre otras industrias.

Requisitos químicos

| El elemento | Composición,% | ||||||||

| Calidad 1A | Calidad 3 | Calificación 4 | Calidad 6A | Calidad 7 | Grado 8 | Calidad 9 | Calidad 10 | Calidad 11 | |

| Carbono,máx | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| El manganeso | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 max | 0.90 max | 0.40-1.06 | 1.15-1.50 | 0.60 Máximo |

| Fósforo, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Azufre, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| El silicio | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 min | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 max |

| Níquel | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 Máximo | 35.0 -37.0 |

| Cromo | - | - | 0.44-1.01 | - | - | - | - | 0.15 max | 0.50 max |

| Cobre | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 max | - |

| Aluminio | - | - | 0.04-0.30 | - | - | - | - | 0.06max | - |

| Vanadio, max | - | - | - | - | - | - | - | 0.12 | - |

| Columbio, max | - | - | - | - | - | - | - | 0.05 | - |

| Molibdeno, max | - | - | - | - | - | - | - | 0.05 | 0.50 max |

| De cobre | - | - | - | - | - | - | - | - | 0.50 max |

Requisitos de tracción

| Clase 1 | Calidad 3 | Grado 6 | Calidad 7 | |||||

| psi | Mpa | psi | Mpa | psi | Mpa | psi | Mpa | |

| Resistencia a la tracción, mínima Resistencia a la flexión, mínima | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Longitudinal | Transversal | El número de unidades | Transversal | El número de unidades | Transversal | El número de unidades | Transversal | |

| Alargamiento en 2 pulgadas o 50 mm, (o 40). mín, %: Alargamiento básico mínimo para paredes de 5/16 pulg. (8 mm) y superior en espesor, pruebas de tira y para todos los pequeños tamaños probados en sección completaCuando estándar redondo de 2 pulg. o 50 mm de longitud de prueba longitud o proporcionalmente más pequeño muestra de prueba con la longitud de prueba igual a 4D (4 veces el diámetro) es usadoPara pruebas de tira, una deducción por cada 1/32 pulg. [0,8 mm] de disminución en el grosor de pared por debajo de 5/16 pulg. (8 mm) del elongación mínima básica del siguiente porcentaje |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| Grado 8 | Calidad 9 | Calidad 10 | Calidad 11 | |||||

| psi | Mpa | psi | Mpa | psi | Mpa | psi | Mpa | |

| Resistencia a la tracción, mínima Resistencia a la flexión, mínima | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Longitudinal | Transversal | El número de unidades | Transversal | El número de unidades | Transversal | El número de unidades | ||

| Elongación en 2 pulg. o 50mm, (o 40). mín, %: Básica elongación mínima para paredes de 5/16 pulg. (8 mm) y superior en espesor, pruebas de tira. Y para todos los tamaños pequeños probados en sección completa. Cuando el estándar redondo de 2 pulg. o 50 mm de longitud de brida o tamaño de prueba proporcionalmente más pequeño con la longitud de brida igual a 4D (4 veces el diámetro) es utilizado. Para pruebas de tira, una deducción por cada 1/32 pulg. [0.8 mm] disminución en el espesor de la pared por debajo de 5/16 pulg. (8 mm) desde la elongación mínima básica del siguiente porcentaje |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Descripción

1. Introducción breve del producto

El tubo de acero sin costura de baja temperatura se utiliza principalmente en el petróleo, la química, el gas natural y el carbón como materias primas para etileno, propileno, urea, amoníaco sintético, fertilizantes compuestos N-P-K y la industria farmacéutica en procesos de lavado, purificación, desulfuración y desengrasado. También se emplea en la fabricación de equipos criogénicos, almacenamiento ultrafrío, transporte de gases licuados a ultra baja temperatura y componentes de tuberías. El sistema internacional de tubos de acero sin costura de baja temperatura está representado por ASTM A333/A333M-2011 (en adelante denominado estándar estadounidense), que es adecuado para entornos de baja temperatura hasta -196℃. Actualmente, la producción y aceptación de tubos de acero sin costura de baja temperatura en todo el mundo utilizan principalmente el estándar estadounidense, y el diseño nacional también hace referencia al estándar estadounidense. Entre los nueve grados del estándar estadounidense de tubería criogénica, Gr.6 es ampliamente utilizado en la industria petroquímica y en el transporte de fluidos en áreas de baja temperatura y frías, con una demanda anual en los mercados de EE.UU. y Europa superior a 20,000 t.

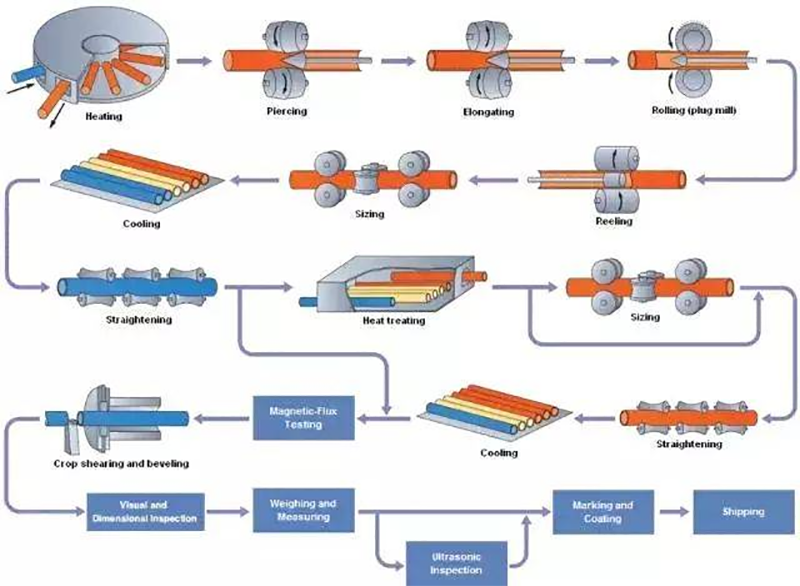

2. Proceso de fabricación

Fabricación - Los tubos se fabrican mediante procesos de soldadura que son sin costura o no añaden metal de relleno. El nivel 4 deberá fabricarse mediante un proceso sin costura.

Tratamiento térmico

Todos los tubos sin costura y con costura deberán ser tratados térmicamente para controlar su microestructura mediante uno de los siguientes métodos.

Calentado uniformemente a no menos de 1500F (815℃) para un tratamiento térmico positivo, y luego enfriamiento al aire o enfriamiento en la cámara de enfriamiento del horno de aire oxígeno controlado.

El tubo de acero se normaliza y se recalienta a una temperatura adecuada de temple, determinada por la fábrica de acero. El recaliente del tubo controla bien el procesamiento en caliente, de modo que la temperatura de funcionamiento del conformado en caliente se controla dentro del rango de temperatura de conformado en caliente de 1550 a 1750F (845-945 ° C), y luego se enfría en el horno de gas oxígeno controlado con una temperatura inicial de no menos de 1550 (845 ° C). Este método solo es adecuado para procesos de tubos sin costura.

Se trata y se vuelve a calentar a la temperatura adecuada de templado, tal como lo determine la fábrica.

Cuando se especifique en el pedido, la muestra se cortará del bloque de prueba de espesor, que se toma de la tubería de acero del lote tratado térmicamente, y deberá estar libre de tensiones. El bloque de prueba se calentará progresivamente hasta la temperatura especificada, se mantendrá húmedo a esta temperatura durante el tiempo especificado y luego se enfriará a una temperatura no superior a 600F (315 °C). El bloque de prueba de la tubería de acero de grado 8 se enfriará al aire o en agua a una velocidad mínima de enfriamiento de 300F/ (165℃/h) hasta una temperatura no superior a 600F (315℃).

3. La marca principal o el tipo de acero del producto

ASTM A333-Grade1, Grade4, Grade6, Grade7, Grade9, Grade10

ASTM A334-Grade1, Grade6, Grade7, Grade9

API 5CT80, L80-1, L803Cr, P110

4. Normas de implementación del producto

GSTM 8333, GSTM 8334, API SPEC 5CT (9ª edición)

5. Característica del producto

La empresa es resistente a bajas temperaturas y no vascular, el uso de acero de alta pureza con bajo contenido de azufre y fósforo y el tratamiento de calcificación puede reducir efectivamente la fragilidad a bajas temperaturas del acero y mejorar la tenacidad al impacto de los productos. La empresa cuenta con un tanque de enfriamiento de 0 "-100C, lo que permite realizar pruebas de impacto a bajas temperaturas por lotes para garantizar la calidad y estabilidad de los productos.

6. Entorno de uso del producto

Los tubos criogénicos A333 y A334 se utilizan para tuberías de recipientes criogénicos de grado -45 a -195C y para tuberías de intercambiadores de calor criogénico. También pueden usarse como tuberías de transporte de fluidos en entornos de baja temperatura. La funda API5CT resistente a bajas temperaturas se utiliza principalmente para perforar pozos en áreas extremadamente frías. El tubo de acero puede usarse a temperaturas extremadamente bajas, pero también tiene alta resistencia, resistencia a la corrosión, buena procesabilidad y capacidad de soldadura. Estas características hacen que el tubo de acero para bajas temperaturas A333GR.6 sea ampliamente utilizado en los campos industriales del petróleo, gas natural, química y otros.

7. Rango de especificaciones del producto

Diámetro exterior: 16mm~323.9mm; Espesor de pared: 2.0mm~40.0mm

Aplicaciones:

Ampliamente utilizado en los campos del petroquímico, gas natural, química, electricidad, calefacción y otros. Su amplio rango de aplicaciones, flexible, en oleoductos y gasoductos, equipos petroquímicos, sistemas de ductos de aire acondicionado, enfriadores, generadores de vapor, además se utiliza en el procesamiento mecánico, recipientes a presión, fabricación de calderas, construcción de estructuras de acero, recintos grandes, centros de exposición, maquinaria de elevación, construcción naval, estantes de almacenamiento, decoración, instalaciones de transporte, construcción de aeropuertos, apoyo de puentes, soporte minero, garajes tridimensionales, publicidad al aire libre, equipo de fitness, fabricación de vehículos y otras industrias.

Especificaciones:

Estándares de tubería de acero sin costura

| API SPEC 5L | |||

| Nombre del producto | Estándar ejecutivo | Dimensión (mm) | Código de Acero / Calificación de Acero |

| Tubos de Línea | Api 5l | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| El número de unidades de producción | |||

| Nombre del producto | Estándar ejecutivo | Dimensión (mm) | Código de Acero / Calificación de Acero |

| Casing | El número de unidades de producción | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubing | El número de unidades de producción | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Nombre del producto | Estándar ejecutivo | Dimensión (mm) | Código de Acero / Calificación de Acero |

| Tubos de acero sin costura negros y galvanizados por inmersión en caliente | Las demás partidas de los componentes | ø10.3~1200xET1.0~150 | Gr.A, Gr.B, Gr.C |

| Tubos de acero al carbono sin costura para servicio a alta temperatura | Astm a106 | ø10.3~1200xET1.0~150 | Gr.B, Gr.C |

| Tubos de intercambiadores de calor y condensadores de acero al carbono de bajo contenido en carbono sin costura y estirados fríamente | ASTM A179 | ø10.3~426x ET1.0~36 | Acero de bajo carbono |

| Tubos de caldera de acero al carbono sin costura para alta presión | ASTM A192 | ø10.3~426 x WT1.0~36 | Acero de bajo carbono |

| Tubos de intercambiadores de calor y condensadores de acero aluminado sin costura, dibujados en frío | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Tubos de calderas y sobrecalentadores de acero al carbono medio sin costura | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Tubos de calderas, sobrecalentadores e intercambiadores de calor de acero ferrítico y austenítico aluminado sin costura | Astm a213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Acero al carbono y acero aleado sin costura para tubos mecánicos | Las demás partidas de los componentes de los equipos de ensayo | ø1/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Tubos de acero al carbono y acero aleado sin costura y con costura para uso a bajas temperaturas | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Tubos de calentador de agua de acero al carbono sin costura y laminados en frío | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| El | |||

| Nombre del producto | Estándar ejecutivo | Dimensión (mm) | Código de Acero / Calificación de Acero |

| Tubos de Acero Sin Costura para Temperaturas Elevadas | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Tubos de Acero Sin Costura | DIN 1629 / DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Tubos de Acero Sin Costura | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Tubos de Acero Sin Costura para Propósitos Estructurales | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| No hay nada. | |||

| Nombre del producto | Estándar ejecutivo | Dimensión (mm) | Código de Acero / Calificación de Acero |

| Tubos de Acero Sin Costura para Estructuras de Máquinas | BS 970 | ø10~762x WT1.0~120 | Acero al carbono |

| Tubos de Acero Sin Costura para Calderas y Cambiadores de Calor | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Ventaja Competitiva:

1. Peso ligero.

El parámetro es 1/5 del acero cuadrado, por lo que tiene un mejor rendimiento en peso y ligereza, siendo más ligero que el acero cuadrado, y su peso es solo 1/5 del acero cuadrado.

2. Resistencia a la corrosión y a altas temperaturas.

Tiene buena resistencia a la corrosión y a altas temperaturas, mejor que el acero cuadrado, A333 resistente a la corrosión por ácidos, álcalis, sales y al ambiente atmosférico, resistente a altas temperaturas, con buena resistencia al impacto y a la fatiga, no requiere mantenimiento regular, y su vida útil efectiva puede alcanzar más de 15 años.

3, sin deformación y antiestático.

Tiene buenas propiedades antiestáticas, mejores que las de los tubos de acero comunes, los tubos sin costura son muy elásticos, reutilizables en equipos mecánicos, sin memoria, sin deformación y antiestáticos, los tubos sin costura tienen excelentes propiedades mecánicas, fácil mecanizado, etc.

¡A nuestro amable equipo le encantaría saber de usted!