| Lugar de Origen: | Shandong, China |

| Nombre de la Marca: | Changshengda(CSD) |

| Número de Modelo: | Q195/Q235/Q345 SS400 |

| Certificación: | API, CE, GS, ISO9001 |

| Cantidad Mínima de Pedido: | 20 toneladas |

| Precio: | 545USD/TON-680USD/TON |

| Detalles de Embalaje: | 1. Empaque marino estándar |

| 2. De acuerdo con los requisitos del cliente | |

| Puerto: | Puertos de Shanghái, Tianjin, Qingdao, puedes especificar otros puertos según tus necesidades. |

| Tiempo de entrega: | 8-14días |

| Términos de Pago: | Carta de crédito, transferencia bancaria |

| Capacidad de Suministro: | 100000toneladas/mes |

| Material: | ERW:Q235, Q345, 20#, J55, X42~65, etc. |

| LASW:Q195,Q235,Q345B,X42,X52,X60,S355JRH,S355J0H,S355J2H etc |

Descripción:

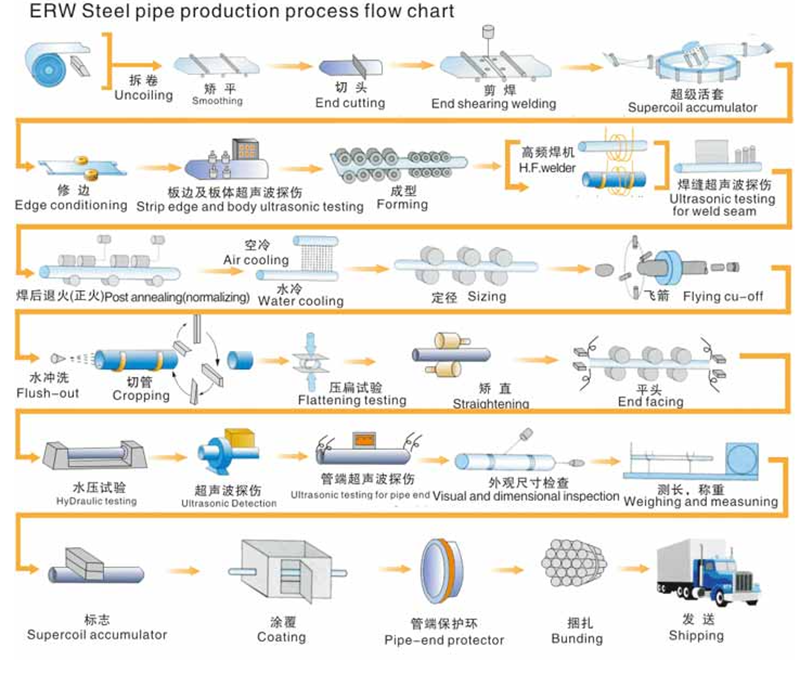

La soldadura de costura recta de alta frecuencia (ERW) se divide en dos formas: soldadura por inducción y soldadura por contacto, según los diferentes métodos de soldadura. Utiliza bobinas anchas de laminación caliente como materia prima y pasa por pre-doblado, formado continuo, soldadura, tratamiento térmico, ajuste de tamaño, enderezado, corte, etc. En comparación con el proceso espiral, tiene las ventajas de tener soldaduras más cortas, alta precisión dimensional, espesor de pared uniforme, buena calidad de superficie y alta resistencia a la presión. Sin embargo, la desventaja es que solo puede producir tubos de pared delgada de diámetros pequeños y medianos, y es propenso a la aparición de manchas grises y falta de fusión en las soldaduras, así como defectos de corrosión en ranuras. Actualmente, los campos de aplicación más extendidos son el gas urbano, el transporte de petróleo crudo y refinado, entre otros.

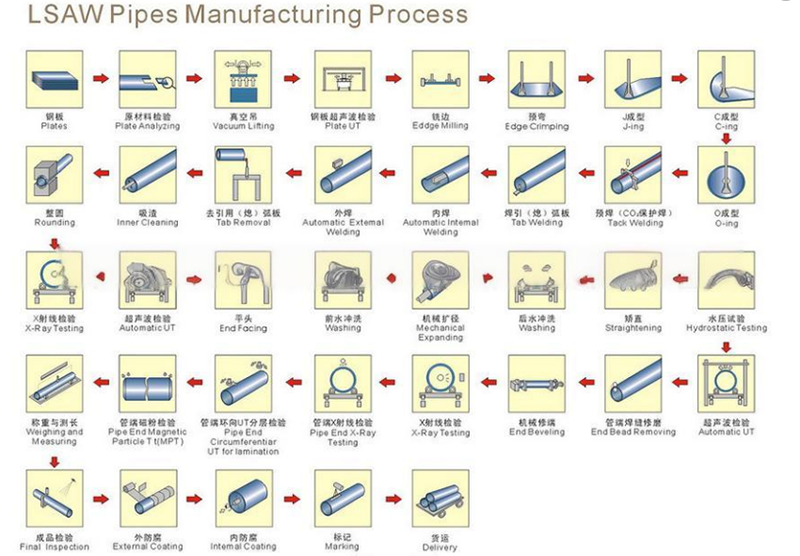

La soldadura de arco sumergido con costura recta (LSAW) se produce utilizando una placa media gruesa como material crudo, presionando (rodando) la placa de acero en un molde o máquina de formación y utilizando soldadura de arco sumergido por ambas caras y expansión del diámetro. El rango de especificaciones de los productos terminados es amplio, la tenacidad, plasticidad, uniformidad y densidad de la soldadura son buenas, y tiene las ventajas de gran diámetro de tubería, pared gruesa, alta resistencia a la presión, resistencia a bajas temperaturas y fuerte resistencia a la corrosión. Al construir tuberías de petróleo y gas a larga distancia de alta resistencia, alta tenacidad y alta calidad, la mayoría de las tuberías de acero requeridas son de gran diámetro, con costura recta y pared gruesa soldada por arco sumergido. Según los estándares API, en grandes tuberías de transporte de petróleo y gas, la soldadura de arco sumergido con junta recta es el único tipo de tubo designado como aplicable al pasar por zonas de la Clase 1 y Clase 2, como zonas montañosas, fondos marinos y áreas urbanas densamente pobladas.

De acuerdo con diferentes métodos de moldeo, se puede dividir en:

Tubo de acero UOE: Después de que la placa de acero simple se pre-dobla en el borde, pasa por procesos como formado en U, formado en O, soldadura interna, soldadura externa y expansión mecánica fría.

Tubo de acero JCOE: es decir, pre-soldadura, formado y expansión fría después de la soldadura según "J-C-O-E"

Tubo de acero HME: formado por el método de laminación con mandril según "C-C-O", soldado y luego expandido fríamente.

Especificaciones:

| Tubo Erw | |

| ASTM | ASTM A53 B, ASTM A178, ASTM A252 GR.2, A500, ASTM A513 |

| EN | EN 10204/10217 S235JR,S275JR,S355,S355JR,S355J2H |

| API | API 5L X42/46/52/56/60/70 |

| Acero al carbono | ASTM A671,ASTM A672 |

| Acero aleado | ASTM A691 |

| OD | 1/2" - 24" (21.3mm-610mm) |

| El | 1.65mm-20mm |

| Aplicación | Tubo de Línea; OCTG (Productos Tubulares para la Industria del Petróleo); Tubo Estructural Redondo; Tubo Recubierto. |

| Tubo de sierra | |||

| Estándar | ASTM 53; API Spec 5L; ASTM A252-89; EN10217, EN10219 | ||

| Grados de acero | API 5L: GR A, GR B, X42, X46, X56, X60, X65, X70 ASTM A252 GR 1, GR 2, GR 3 ASTM A53: GR A, GR B, GR C, GR D BS 4360: Grado 43, Grado 50 EN: S275, S275JR, S355JRH, S355J2H |

||

| Aplicación | Utilizado para petróleo/gas/agua; Transmisión; Ingeniería; Proyectos offshore. | ||

| Uso | Diámetro exterior (mm) | EP(mm) | Longitud (m) |

| Tubo de rodillos | 1200-3800(47.24”-150”) | 12-120 (1/2”- 4.7”) | <=3.2 |

| para Construcción (Pilotes de tubo) | 350-1600(14”- 63”) | 6-60 (1⁄4” -2.36”) | 6-12 |

| Oleoducto y gasoducto | 406-1524(16”- 60”) | 6-40 (1⁄4”-1.57”) | 8-12.1 |

| Además de la especificación anterior, los tubos pueden producirse de acuerdo con los requisitos del cliente. | |||

Detalle rápido:

Descripción:

Tubo de acero de costura recta para conducción de fluidos a baja presión

Diámetro: 219mm~508mm

Espesor de pared: 6mm~20mm

Estándar: GB/T 3091-2008

Material: L245~L690, Q235, etc.

Aplicaciones: Adecuado para tubos de acero soldados con costura longitudinal utilizados en el transporte de fluidos a baja presión como agua, gas, aire y vapor de calefacción, así como otras estructuras.

Tubo de acero soldado con costura longitudinal según estándar americano

Diámetro: 219mm~406mm

Espesor de pared: 6mm~14mm

Estándar: ASTM

Material: GrA GrB

Aplicaciones: Principalmente utilizado en proyectos hidráulicos, industria petrolera y de gas, industria química, industria eléctrica, riego agrícola, construcción urbana, etc.

Tubos de acero con costura longitudinal para revestimientos de pozos de petróleo y tuberías de petróleo

Diámetro 219mm~508mm

Espesor de pared 6mm~20mm

Estándar API-5CT

Material H40, J55, N80, P110

Aplicación: revestimiento y tubería para petróleo.

Tubo de acero soldado en espiral estándar americano

Diámetro 219mm~3520mm

Espesor de pared 5mm~26mm

Estándar ASTM

Material Gr.A, Gr.B, Gr.C, Gr.1~Gr.11

Aplicación: Principalmente utilizado en tuberías de pilotes para proyectos de conservación de agua, industria petrolera y de gas, industria química, industria eléctrica, riego agrícola, construcción urbana, etc.

Tubos de acero con costura longitudinal para transporte de petróleo y gas

Diámetro 219mm~508mm

Espesor de pared 6mm~20mm

Estandar API-5L

Material Gr.B, X42~X100

Aplicación: Utilizado para el transporte de petróleo y gas natural.

Ventaja Competitiva:

La empresa ha seleccionado tecnología y equipos avanzados a nivel internacional: como la molduración W-FF, el soldadura por inducción de alta frecuencia en estado sólido, la detección de defectos por ultrasonidos, la detección de fugas por flujo magnético y equipos de prueba de alta gama: como el análisis metalográfico, la máquina de dureza Vickers, la máquina de prueba de impacto, los analizadores espectrométricos, las máquinas de prueba universal y otros equipos. Desde su establecimiento, ha obtenido diversas certificaciones internacionales y calificaciones honoríficas: como API 5L, API5CT, certificado de producción de tuberías de presión ISO9002-2000, licencia de producción de productos industriales, Certificado de Membresía de Petróleo y Petroquímica de China, Certificado de Producto de Calidad de China, etc. Los productos se exportan a América del Sur, América del Norte, la Unión Europea, Sudeste Asiático y otros lugares. Durante muchos años han sido bien recibidos por clientes de todo el mundo.

¡A nuestro amable equipo le encantaría saber de usted!