| Lugar de Origen: | Shandong, China |

| Nombre de la Marca: | $560-600/TON |

| Número de Modelo: | A106/A53GRB API5L/Q195,Q235,Q275,Q355,Q345,SAE1010/1020,1045, etc |

| Certificación: | API, CE, Bsi, RoHS, SNI, BIS, tisi, KS, JIS, GS, ISO9001 |

| Cantidad Mínima de Pedido: | 1ton |

| Precio: | $560/TON |

| Detalles de Embalaje: | Estándar de Embalaje para Exportación (En paquetes, bolsas de nailon, cajas de madera o según se requiera) |

| Tiempo de Entrega: | 3-7 días |

| Términos de Pago: | FOB 30% T/T, 70% antes del envío |

| CIF 30% pago anticipado y el saldo debe ser pagado antes de hacer el envío | |

| o Crédito Documentario Irrevocable al 100% a la vista | |

| Capacidad de Suministro: | 10000 Toneladas por Mes |

Descripción:

El tubo de acero galvanizado se divide en tubo de acero galvanizado en caliente y tubo de acero galvanizado en frío

Tubería galvanizada por inmersión en caliente

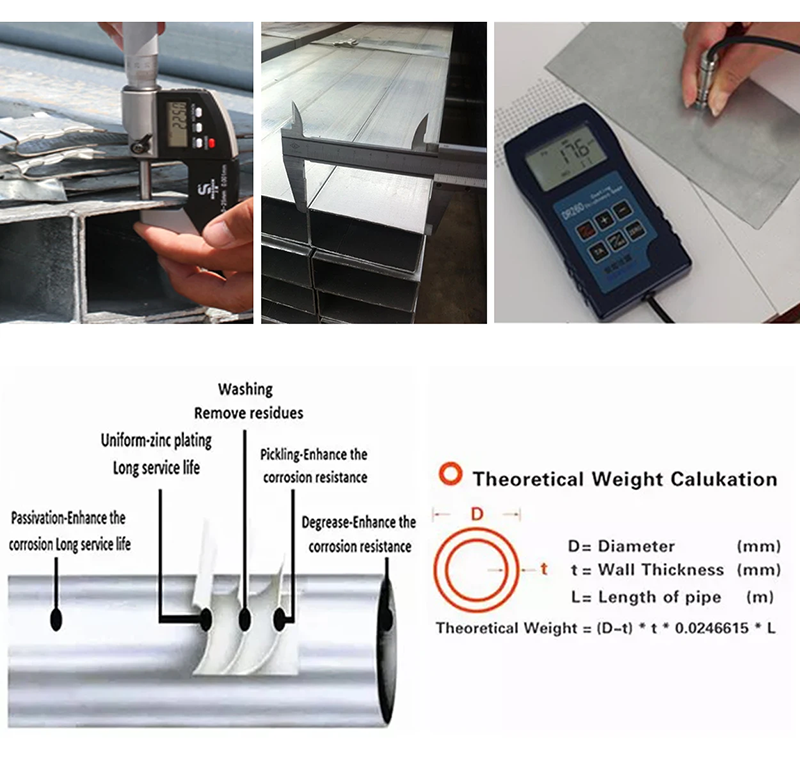

El metal fundido reacciona con una matriz de hierro para producir una capa de aleación, lo que permite unir el sustrato y la capa de recubrimiento. La galvanización en caliente consiste primero en enjuagar el tubo de acero para eliminar el óxido de hierro de la superficie del tubo de acero, después del enjuague, se lava con una solución acuosa de cloruro de amonio o cloruro de zinc o una solución acuosa mixta de cloruro de amonio y cloruro de zinc, y luego se introduce en el tanque de galvanización en caliente. La galvanización en caliente tiene las ventajas de un recubrimiento uniforme, una adherencia fuerte y una vida útil larga. La mayoría de los procesos en el norte utilizan tiras galvanizadas para enrollar directamente el zinc

Tubo galvanizado en frío

La galvanización en frío es la electro-galvanización. La cantidad de galvanización es muy pequeña, solo 10-50g/m2, y su resistencia a la corrosión es mucho peor que la de los tubos galvanizados en caliente. Los fabricantes regulares de tubos galvanizados, para garantizar la calidad, la mayoría no utilizan la electro-galvanización (galvanización en frío). Solo las pequeñas empresas con equipos pequeños y obsoletos usan acero electro-galvanizado, por supuesto, sus precios son relativamente más baratos. En las casas nuevas, está prohibido el uso de tubos de acero galvanizado en frío como tuberías de suministro de agua.

Diferencia entre galvanizado en caliente y galvanizado en frío

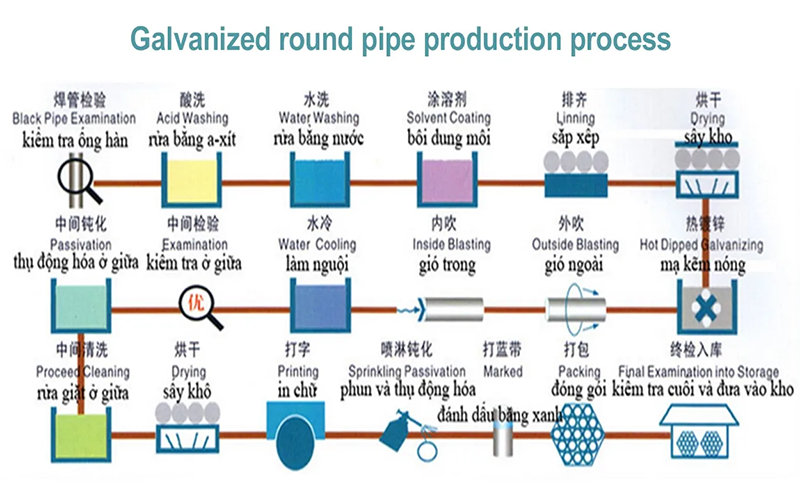

Proceso de galvanizado en caliente:

Desgrasado del pieza → lavado → desescamado → lavado → secado inmersión en solvente fluxado precalentado galvanizado en caliente → enfriamiento → acabado → enjuague → secado → prueba de pasivación

Proceso de galvanizado en frío:

Desengrasado químico → lavado → electrólisis en agua caliente → lavado → lavado → galvanizado de hierro corrugado con corrosión fuerte → lavado → lavado → ligero → → lavado → secado pasivación

Las ventajas de los tubos galvanizados son las siguientes:

Primero, el tubo galvanizado después de ser recubierto por inmersión en caliente puede estar protegido, y dentro de la cavidad del tubo o cualquier otra esquina donde sea difícil entrar con otro recubrimiento, el zinc puede cubrir fácilmente hasta arriba, haciendo que todo el tubo galvanizado pueda estar protegido.

En segundo lugar, después de que la tubería galvanizada sea galvanizada, su resistencia al impacto y a la abrasión es muy buena, ya que el valor de dureza del recubrimiento de zinc es mayor que la dureza del acero, por lo que la resistencia al impacto y a la abrasión después de la galvanización en caliente es bastante buena. Además, la mayor ventaja de la galvanización es que en las esquinas, la capa de zinc será relativamente gruesa y tendrá buena resistencia y flexibilidad a la abrasión, mientras que otros recubrimientos suelen ser los más finos y difíciles de aplicar en estas esquinas, y por lo tanto son propensos a dañarse.

Especificaciones:

| descripción | l Tubo soldado galvanizado | |

| l Calidad del acero | l Astm a53 Gr.B / ASTM A106 | |

| l Estándar | l ASTM A106/A106M;ASTM A53/A53M;API 5L;GB/T 8163-2008;GB/T 8162-2008; BS1387, BS1139, EN39, EN1139, ASTM A53, JIS G3444 | |

| l Material | l A106 Grado A, A106 Grado B, A106 Grado C, A53 Grado A, A53 Grado B, API 5L Grado B, 10#, 20#, 45# | |

| l Superficie | l Galvanizado en caliente; Galvanizado electroquímico; Método solicitado por el cliente | |

| tipo | 1. Pre-pintado (zinc: 60-120G/M2) 2. Galvanizado por inmersión en caliente (zinc: 120-500G/M2) 3. Galvanizado por inmersión fría (zinc: 10-50G/M2) | |

| talla L | espesor de la pared | 1-22mm |

| Diámetro Exterior | 21.3mm-610mm | |

| tiempo de entrega | entrega rápida o según la cantidad del pedido. | |

| paquete | paquete estándar para exportación resistente al transporte marítimo, o según se requiera. | |

| aplicación | l Transporte de fluidos; soporte estructural; HVAC; industria del petróleo y el gas; equipo industrial | |

| l Contacto | l Si tiene alguna pregunta, no dude en contactarme. | |

| l Tamaño del contenedor | l 20ft GP: 5898mm (Largo) x 2352mm (Ancho) x 2393mm (Alto) 24-26CBMl l 40ft GP: 12032mm (Largo) x 2352mm (Ancho) x 2393mm (Alto) 54CBMl l 40ft HC: 12032mm (Largo) x 2352mm (Ancho) x 2698mm (Alto) 68CBM |

|

Detalle rápido:

1.tubo gi, tubería redonda de acero galvanizado por inmersión en caliente, tubo de acero galvanizado, tubo soldado de acero gi

2.Tubería redonda de acero galvanizado por inmersión en caliente (HDG), se utiliza ampliamente en diversas industrias y áreas de construcción en todo el mundo.

El tubo galvanizado frío es galvanizado eléctricamente, la cantidad de galvanización es muy pequeña, solo 10-50g/m2, su resistencia a la corrosión es muy diferente a la del tubo galvanizado en caliente.

Puede ser utilizado en la construcción, maquinaria, minería de carbón, industria química, electricidad, vehículos ferroviarios, industria automotriz, carreteras, puentes, contenedores, instalaciones deportivas, maquinaria agrícola, maquinaria petrolera, maquinaria de exploración y otras industrias manufactureras.

| Propiedades Químicas % | |||||||||

| Grado A | |||||||||

| C | Mn | P | S | ¿Qué es? | Cr | Cu | Mo | Ni | V |

| 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Calificación B | |||||||||

| C | Mn | P | S | ¿Qué es? | Cr | Cu | Mo | Ni | V |

| 0.3 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Calificación C | |||||||||

| C | Mn | P | S | ¿Qué es? | Cr | Cu | Mo | Ni | V |

| 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Propiedades mecánicas | |||

| Grado A | Calificación B | Calificación C | |

| Resistencia a la Tracción | 330 | 415 | 485 |

| Resistencia a la fluencia | 205 | 240 | 275 |

Descripción:

El tubo soldado galvanizado se refiere a un tipo de tubo de acero que ha sido recubierto con una capa de zinc a través de un proceso llamado galvanización.

El proceso de galvanización implica sumergir el tubo de acero en un baño de zinc fundido, lo que forma una capa protectora en la superficie del tubo.

El propósito de galvanizar los tubos soldados es proporcionar resistencia a la corrosión y extender la vida útil del tubo. El recubrimiento de zinc actúa como una barrera entre el acero y el entorno circundante, protegiendo el tubo del óxido y otras formas de corrosión.

Esto hace que los tubos soldados galvanizados sean adecuados para diversas aplicaciones, especialmente en industrias donde la exposición a la humedad o sustancias corrosivas es común.

Algunas de las principales ventajas de los tubos soldados galvanizados incluyen:

1. Resistencia a la corrosión: El recubrimiento de zinc proporciona una excelente resistencia a la corrosión, lo que hace que los tubos galvanizados sean adecuados para aplicaciones al aire libre y subterráneas.

2. Durabilidad: La combinación de acero y el recubrimiento de zinc mejora la fuerza y durabilidad del tubo, permitiéndole

resistir condiciones severas y un uso intensivo.

3. Eficiencia en costo: Los tubos soldados galvanizados son generalmente más asequibles en comparación con otras alternativas resistentes a la corrosión, lo que los convierte en una opción económica para diversos proyectos.

4. Instalación fácil: Los tubos soldados galvanizados son relativamente fáciles de instalar debido a sus tamaños estandarizados y compatibilidad

con accesorios y conectores comúnmente utilizados.

5. Versatilidad: Los tubos soldados galvanizados están disponibles en varios tamaños y espesores, lo que los hace adecuados para una amplia gama de aplicaciones, incluyendo plomería, construcción, agricultura y proyectos industriales.

Es importante tener en cuenta que las tuberías soldadas galvanizadas tienen limitaciones. Con el tiempo, el recubrimiento de zinc puede degradarse o desgastarse,

especialmente en entornos altamente corrosivos. Por lo tanto, es necesario realizar inspecciones y mantenimiento regulares para garantizar la protección continua de la tubería.

Además, al trabajar con tuberías soldadas galvanizadas, es importante tomar las precauciones de seguridad adecuadas, como usar

equipo de protección personal adecuado y asegurar una ventilación adecuada, ya que el proceso de galvanización puede liberar gases que pueden ser dañinos si se inhalan.

Aplicaciones:

construcción, maquinaria, minería de carbón, industria química, electricidad, vehículos ferroviarios, industria automotriz, carreteras, puentes, contenedores, instalaciones deportivas, maquinaria agrícola, maquinaria petrolera, maquinaria de exploración y otras industrias manufactureras.

Especificaciones:

| Tubo de Acero Redondo Galvanizado | |||||||||

| Estándar: API 5L, API 5CT, ASTM A53, ASTM A500, GB9711.1 Aplicación: Para ser utilizado en el transporte de gas, agua y petróleo para las industrias de petróleo y gas natural y se utiliza para el propósito de tubos de acero estructural. Grado principal de Tubo de Acero: GR.A, GR.B, GR.C, Q195, Q235B, Q345B y otros. |

|||||||||

| Pulgada | Diámetro exterior (mm) | Espesor Estándar de Pared | |||||||

| SCH 10WT (mm) | SCH 20WT (mm) | SCH 40WT (mm) | SCH 60WT (mm) | SCH 80WT (mm) | SCH 100WT (mm) | SCH 160WT (mm) | XXS (mm) | ||

| 1/4” | 13.7 | 2.24 | 3.02 | ||||||

| 3/8" | 17.1 | 2.31 | 3.2 | ||||||

| 1/2 | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" de largo | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| ¿Qué es eso? | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2 y media. | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1⁄2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" de largo | 114.3 | 3.05 | 4.5 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" de largo | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" de largo | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" de largo | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.7 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.7 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" de largo | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

| 30" | 762 | 7.92 | 12.7 | ||||||

| 32" | 813 | 7.92 | 12.7 | 17.48 | |||||

| 34" de largo | 863 | 7.92 | 12.7 | 17.48 | |||||

| 36" | 914 | 7.92 | 12.7 | 19.05 | |||||

| 38" de largo | 965 | ||||||||

| 40" de largo | 1016 | ||||||||

| 42" de largo | 1066 | ||||||||

| 44" de largo | 1117 | ||||||||

| 46" | 1168 | ||||||||

| 48" | 1219 | ||||||||

Ventaja Competitiva:

Tenemos precios competitivos y ventajas de entrega oportuna en el suministro de tubos de acero sin costura, no solo para clientes por volumen, sino que también aceptamos pedidos personalizados de diseño, especificaciones y requisitos de embalaje de los clientes.

¡A nuestro amable equipo le encantaría saber de usted!