| Lieu d'origine : | Shandong, Chine |

| Nom de la marque : | jinzheng |

| Numéro du modèle : | 16MnDG, 10MnDG, 09DG, 09Mn2VDG, 06Ni3MoDG, ASTM A333-Grade1, Grade3, Grade4, Grade6, Grade7, Grade8, Grade9, Grade10, Grade11 |

| Certification : | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| Quantité minimale de commande : | 1 tonne |

| Prix : | $650/tonne |

| Détails d'emballage : | Norme d'emballage pour l'exportation (En paquets Nylon, caisses en bois ou selon les exigences) |

| Délai de livraison : | 15-20 jours |

| Conditions de paiement : | FOB 30% T/T, 70% avant expédition |

| CIF 30% d'acompte et le solde à payer avant l'expédition | |

| ou Lettre de crédit irrévocable à 100% au vu | |

| Capacité d'approvisionnement : | 2000 Tonne/Tonnes par mois |

Détail rapide :

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,tube sans soudure,Tubes en acier au carbone et alliages sans soudure pour applications mécaniques

Le tube en acier pour basses températures A333 est largement utilisé dans les secteurs pétrochimiques, le gaz naturel, la chimie, l'électricité, le chauffage et autres. Sa gamme d'applications est vaste et flexible, notamment dans les pipelines de transport de pétrole et de gaz naturel, les équipements pétrochimiques, les systèmes de climatisation, les réfrigérateurs, les générateurs à vapeur, ainsi que dans le traitement mécanique, les récipients sous pression, la fabrication de chaudières, la construction d'acier structurel, les grands lieux publics, les centres d'exposition, les machines de levage, la construction navale, les rayonnages de stockage, la décoration, les infrastructures de transport, la construction d'aéroports, les supports de ponts, les garages en 3D, la publicité extérieure, les équipements de fitness et la fabrication de véhicules ainsi que dans d'autres industries.

Exigences chimiques

| Élément | Composition, % | ||||||||

| Classe 1A | Classe 3 | Classe 4 | Classe 6A | Classe 7 | 8e année | Classe 9 | Classe 10 | Classe 11 | |

| Carbone, max | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| D'autres produits | 0,40-1,06 | 0,31-0,64 | 0,50-1,05 | 0.29-1.06 | 0,90 max | 0,90 max | 0,40-1,06 | 1,15-1,50 | 0.60 Max |

| Phosphore, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Soufre, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Silicium | - | 0,18- 0,37 | 0,08- 0,37 | 0,10 min | 013- 0,32 | 0,13 0,32 | - | 0,10-0,35 | 0,35 max |

| Autres produits | - | 3,18- 3,82 | 0,47-0,98 | - | 2,03 2 57 | 8,40 9,60 | 1,60 2,24 | 0,25 Max | 35,0 -37,0 |

| Chrome | - | - | 0,44-1,01 | - | - | - | - | 0,15 max | 0,50 max |

| Cuivre | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0,15 max | - |

| Aluminium | - | - | 0.04-0.30 | - | - | - | - | 0,06 max | - |

| Vanadium, max | - | - | - | - | - | - | - | 0.12 | - |

| Columbium, max | - | - | - | - | - | - | - | 0.05 | - |

| Molybdenum, max | - | - | - | - | - | - | - | 0.05 | 0,50 max |

| Cobalt | - | - | - | - | - | - | - | - | 0,50 max |

Exigences en traction

| Classe 1 | Classe 3 | Grade 6 | Classe 7 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Résistance à la traction, min Résistance à la flexion, min | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Longitudinale | Transversale | Légendaire | Transversale | Légendaire | Transversale | Légendaire | Transversale | |

| Allongement en 2 po ou 50 mm, (ou 40). min, % : Allongement minimum de base pour murs de 5/16 po (8 mm) et plus en épaisseur, tests en bandelette et pour toutes petites dimensions testées en section complèteLorsque standard rond de 2 po. ou jauge de 50 mm longueur ou taille proportionnellement plus petite échantillon d'essai avec la longueur de jauge égale à 4D (4 fois le diamètre) est utilisée. Pour les essais de bande, une déduction pour chaque diminution de 1/32 po. [0,8 mm] en épaisseur de paroi en dessous de 5/16 po. (8 mm) du pourcentage minimum d'allongement de base du pourcentage suivant |

35 28 1,75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16,5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| 8e année | Classe 9 | Classe 10 | Classe 11 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Résistance à la traction, min Résistance à la flexion, min | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Longitudinale | Transversale | Légendaire | Transversale | Légendaire | Transversale | Légendaire | ||

| Allongement en 2 po ou 50 mm, (ou 40). min, % : de base allongement minimum pour les parois de 5/16 po (8 mm) et plus en épaisseur, tests de bandelettes. Et pour toutes petites dimensions testées en section complète. Lorsque la norme ronde de 2 po ou 50 mm est utilisée comme longueur d'éprouvette proportionnellement plus petite avec la longueur utile égale à 4D (4 fois le diamètre) est utilisée. Pour les tests de bandelettes, une déduction pour chaque 1/32 po [0,8 mm] de diminution de l'épaisseur des parois en dessous de 5/16 po (8 mm) à partir de l'allongement minimum de base pourcentage suivant |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Description

1. Présentation succincte du produit

Le tube d'acier sans soudure à basse température est principalement utilisé dans les secteurs du pétrole, de la chimie, du gaz naturel et du charbon comme matières premières pour l'éthylène, le propylène, l'urée, l'ammoniac synthétique, les engrais composites N-P-K et l'industrie pharmaceutique, pour les processus de lavage, de purification, de désulfuration et de dégraissage, ainsi que pour la fabrication d'équipements cryogéniques, les entrepôts ultra-froids, le transport de gaz liquéfiés à ultra-basse température et les composants tubulaires. Le système international de tubes d'acier sans soudure à basse température est représenté par ASTM A333/A333M-2011 (ci-après dénommé la norme américaine), qui convient aux environnements à basse température allant jusqu'à -196℃. Actuellement, la production et l'acceptation des tubes d'acier sans soudure à basse température dans le monde utilisent majoritairement la norme américaine, et les conceptions nationales se réfèrent également à cette norme. Parmi les neuf grades de tuyaux cryogéniques selon la norme américaine, le grade Gr.6 est largement utilisé dans l'industrie pétrochimique et le transport de fluides dans les régions froides et à basse température, avec une demande annuelle de plus de 20 000 tonnes sur les marchés américain et européen.

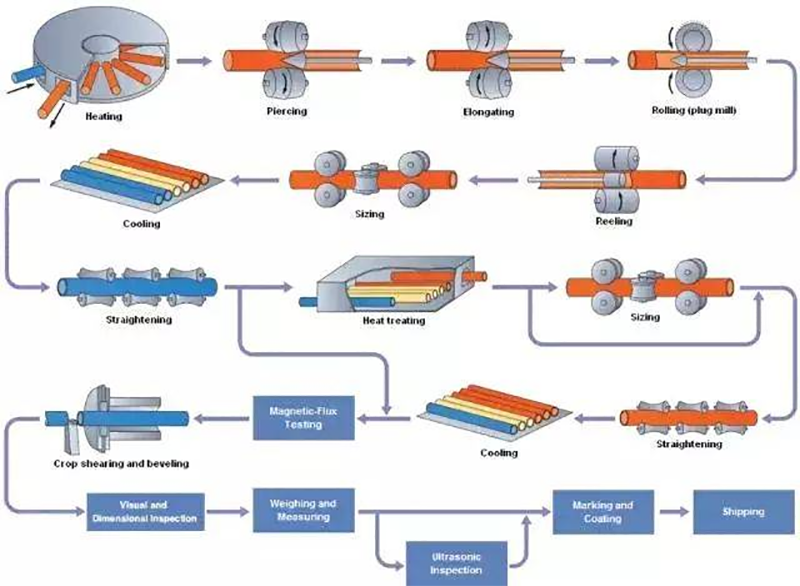

2. Procédé de fabrication

Fabrication - Les tubes sont fabriqués par des procédés de soudage qui sont sans couture ou ne ajoutent pas de métal de remplissage. Le niveau 4 doit être fabriqué par un procédé sans couture.

Traitement thermique

Tous les tubes sans soudure et soudés doivent être soumis à un traitement thermique pour contrôler leur microstructure par l'une des méthodes suivantes.

Réchauffés uniformément à au moins 1500°F (815°C) pour un traitement thermique positif, puis refroidis à l'air ou dans la chambre de refroidissement d'un four à air oxygéné contrôlé.

Le tube en acier est normalisé et réchauffé à une température appropriée de trempe déterminée par l'aciérie. Le réchauffage du tube contrôle bien le traitement thermique, de sorte que la température de fonctionnement du formage thermique est maintenue dans la plage de température de formage thermique de 1550 à 1750°F (845-945°C), puis il est refroidi dans un four à air oxygéné contrôlé avec une température initiale d'au moins 1550°F (845°C). Cette méthode n'est applicable qu'aux procédés de tube sans couture.

Il est traité et réchauffé à la température appropriée de trempe, telle que déterminée par l'usine.

Lorsqu'il est spécifié dans la commande, l'échantillon doit être découpé à partir du bloc d'essai d'épaisseur, qui est prélevé à partir du tube en acier traité thermiquement, et doit être soumis à un soulagement des contraintes. Le bloc d'essai doit être chauffé progressivement jusqu'à la température spécifiée, humidifié à cette température pendant le temps spécifié, puis refroidi à une température n'excédant pas 600F (315 ° C). Le bloc d'essai du tube en acier de grade 8 doit être refroidi à l'air ou à l'eau à un taux minimum de refroidissement de 300F/ (165℃/h) jusqu'à une température n'excédant pas 600F (315℃).

3. La marque principale ou le type d'acier du produit

ASTM A333-Grade1, Grade4, Grade6, Grade7, Grade9, Grade10

ASTM A334-Grade1, Grade6, Grade7, Grade9

API 5CT80, L80-1, L803Cr, P110

4. Normes d'exécution du produit

GSTM 8333, GSTM 8334, API SPEC 5CT (9ᵉ édition)

5. Caractéristique du produit

L'entreprise est résistante au froid et sans vaisseaux sanguins, l'utilisation d'acier de haute pureté à faible teneur en soufre et en phosphore avec un traitement de calcification peut réduire efficacement la fragilité à basse température de l'acier et améliorer la tenue aux chocs des produits. L'entreprise dispose d'un bain de refroidissement de 0 °C à -100 °C, ce qui permet de réaliser des tests d'impact à basse température en série pour garantir la qualité et la stabilité des produits.

6. Environnement d'utilisation du produit

Les tubes cryogéniques A333 et A334 sont utilisés pour les tuyaux de vaisseaux cryogéniques de -45 à -195 °C, ainsi que pour les tuyaux d'échangeurs de chaleur cryogéniques. Ils peuvent également être utilisés comme tuyaux de transport de fluide dans des environnements à basse température. L'enveloppe résistante au froid API5CT est principalement utilisée pour le forage de puits en zones extrêmement froides. Le tube en acier peut être utilisé à des températures extrêmement basses, mais possède également une grande résistance, une résistance à la corrosion, de bonnes propriétés de traitement et de soudabilité. Ces caractéristiques font que le tube en acier A333GR.6 à faible température est largement utilisé dans les domaines industriels du pétrole, du gaz naturel et de la chimie.

7. Plage des spécifications du produit

Diamètre extérieur : 16 mm ~ 323,9 mm ; Épaisseur de paroi : 2,0 mm ~ 40,0 mm

Applications :

Amplement utilisé dans les secteurs pétrochimique, gaz naturel, chimie, électricité, chauffage et autres. Sa large gamme d'applications, sa flexibilité, dans les pipelines de transport de pétrole et de gaz naturel, les équipements pétrochimiques, les systèmes de canalisations de climatisation, les refroidisseurs, les générateurs de vapeur, mais aussi utilisé dans le traitement mécanique, les récipients sous pression, la fabrication de chaudières, la construction en acier, les grands lieux, les centres d'exposition, les machines de levage, la construction navale, les rayonnages de stockage, la décoration, les infrastructures de transport, la construction d'aéroports, les supports de ponts, les supports miniers, les parkings en trois dimensions, la publicité extérieure, les équipements de fitness, la fabrication de véhicules et d'autres industries.

Spécifications :

Normes des tubes d'acier sans soudure

| API SPEC 5L | |||

| Nom du produit | Norme Exécutive | Dimension (mm) | Code acier / Classe acier |

| Tubes de ligne | Api 5l | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| Nom du produit | Norme Exécutive | Dimension (mm) | Code acier / Classe acier |

| Casing | Spécifications API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubage | Spécifications API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Nom du produit | Norme Exécutive | Dimension (mm) | Code acier / Classe acier |

| Tubes en acier sans soudure noirs et galvanisés à immersion chaude | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Tubes en acier au carbone sans soudure pour service à haute température | Astm a106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Tubes échangeurs de chaleur et condenseurs en acier au carbone faible tirés à froid sans soudure | ASTM A179 | ø10.3~426x WT1.0~36 | Acier au faible carbone |

| Tubes de chauffe-eau en acier au carbone sans soudure pour haute pression | ASTM A192 | ø10.3~426 x WT1.0~36 | Acier au faible carbone |

| Tubes d'échangeur de chaleur et de condenseur en acier allié sans soudure, tirés à froid | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Tubes pour chaudière et surchauffeur en acier au carbone moyen sans soudure | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Tubes pour chaudière, surchauffeur et échangeur de chaleur en acier allié ferritique et austénitique sans soudure | Astm a213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Acier au carbone et acier allié sans soudure pour tubes mécaniques | ASTM A333 | ø1/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Tubes en acier au carbone et en acier allié sans et avec soudure pour une utilisation à basse température | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Tubes d'échangeur de chaleur en acier au carbone tiré à froid sans soudure | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Nom du produit | Norme Exécutive | Dimension (mm) | Code acier / Classe acier |

| Tubes en acier sans soudure pour températures élevées | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Tubes en acier sans soudure | DIN 1629 / DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Tubes en acier sans soudure | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Tubes en acier sans soudure pour usage structurel | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| Je vous en prie. | |||

| Nom du produit | Norme Exécutive | Dimension (mm) | Code acier / Classe acier |

| Tubes en acier sans soudure pour structures de machine | BS 970 | ø10~762x WT1.0~120 | Acier au carbone |

| Tubes en acier sans soudure pour chaudières et échangeurs de chaleur | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Avantage concurrentiel :

1. Poids léger.

Le paramètre est de 1/5 de l'acier carré, donc il offre de meilleures performances en termes de poids et de légèreté, plus léger que l'acier carré, et son poids ne représente que 1/5 de celui de l'acier carré.

2. Résistance à la corrosion et aux hautes températures.

Il présente une bonne résistance à la corrosion et aux hautes températures, meilleure que celle de l'acier carré, A333 résistant à la corrosion causée par les acides, les bases, les sels et l'environnement atmosphérique, résistant aux hautes températures, avec une bonne résistance aux chocs et à la fatigue, n'a pas besoin d'entretien régulier, et sa durée de vie effective peut atteindre plus de 15 ans.

3, sans déformation et anti-statique.

Il présente de bonnes propriétés anti-statiques, meilleures que celles des tubes en acier ordinaires, les tubes sans soudure sont très élastiques, réutilisables dans les équipements mécaniques, sans mémoire, sans déformation, et anti-statiques, les tubes sans soudure possèdent d'excellentes propriétés mécaniques, facilement usinables, etc.

Notre équipe aimable aimerait vous entendre!