| Lieu d'origine : | Shandong, Chine |

| Nom de la marque : | $560-600/TON |

| Numéro du modèle : | A106/A53GRB API5L/Q195,Q235,Q275,Q355,Q345,/SAE1010/1020,1045,etc |

| Certification : | API, CE, Bsi, RoHS, SNI, BIS, tisi, KS, JIS, GS, ISO9001 |

| Quantité minimale de commande : | 1Ton |

| Prix : | $560/TON |

| Détails d'emballage : | Norme d'emballage pour l'exportation (En paquets, sacs en nylon, caisses en bois ou selon les exigences) |

| Délai de livraison : | 3-7jours |

| Conditions de paiement : | FOB 30% T/T, 70% avant expédition |

| CIF 30% d'acompte et le solde à payer avant l'expédition | |

| ou Lettre de crédit irrévocable à 100% au vu | |

| Capacité d'approvisionnement : | 10000 Tonnes par mois |

Description :

Le tube en acier galvanisé se divise en tube en acier galvanisé à chaud et tube en acier galvanisé à froid

Tuyau galvanisé à chaud

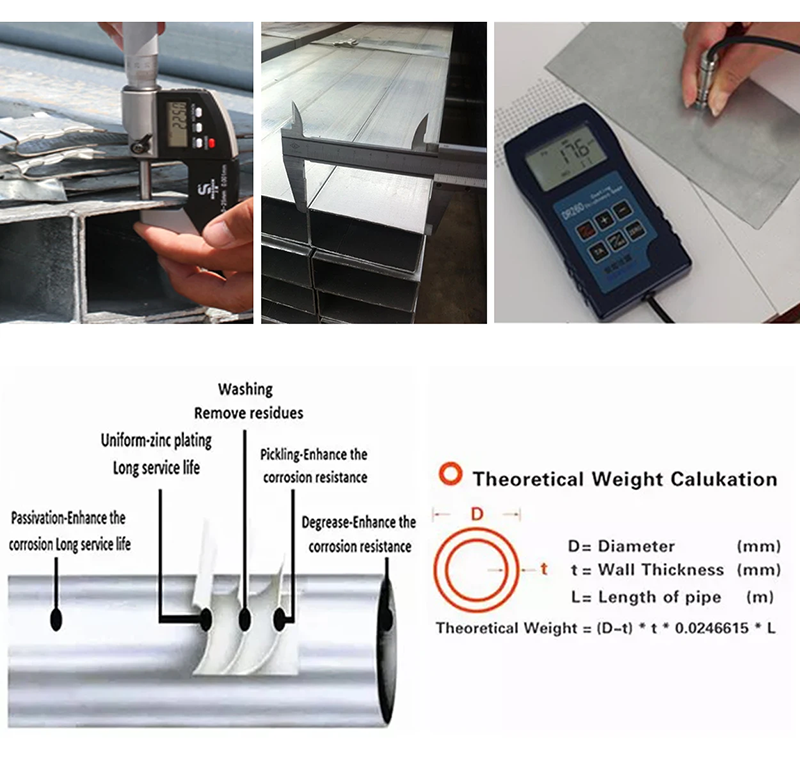

Le métal fondu réagit avec une matrice en fer pour produire une couche d'alliage, ce qui permet de combiner le substrat et la couche de revêtement. La galvanisation à chaud consiste d'abord à aiguiser le tube en acier, afin d'enlever l'oxyde de fer sur la surface du tube en acier, après l'aiguisage, il est lavé avec une solution aqueuse de chlorure d'ammonium ou de chlorure de zinc ou une solution aqueuse mixte de chlorure d'ammonium et de chlorure de zinc, puis introduit dans la cuve de galvanisation à chaud. La galvanisation à chaud présente les avantages d'un revêtement uniforme, d'une forte adhérence et d'une longue durée de vie. La plupart des procédés utilisés dans le nord utilisent des bandes galvanisées pour enrouler directement le zinc.

Tube galvanisé à froid

La galvanisation à froid est l'électrogalvanisation. La quantité de galvanisation est très faible, seulement 10-50g/m2, et sa résistance à la corrosion est beaucoup plus mauvaise que celle des tubes galvanisés à chaud. Les fabricants de tubes galvanisés réguliers, pour garantir la qualité, n'utilisent en général pas l'électrogalvanisation (galvanisation à froid). Seules les petites entreprises avec un petit équipement et des machines vieillissantes utilisent l'acier électrogalvanisé, bien sûr, leurs prix sont relativement moins chers. Dans les maisons neuves, l'utilisation de tubes en acier galvanisé à froid comme tuyaux d'alimentation en eau est interdite.

Différence entre la galvanisation à chaud et la galvanisation à froid

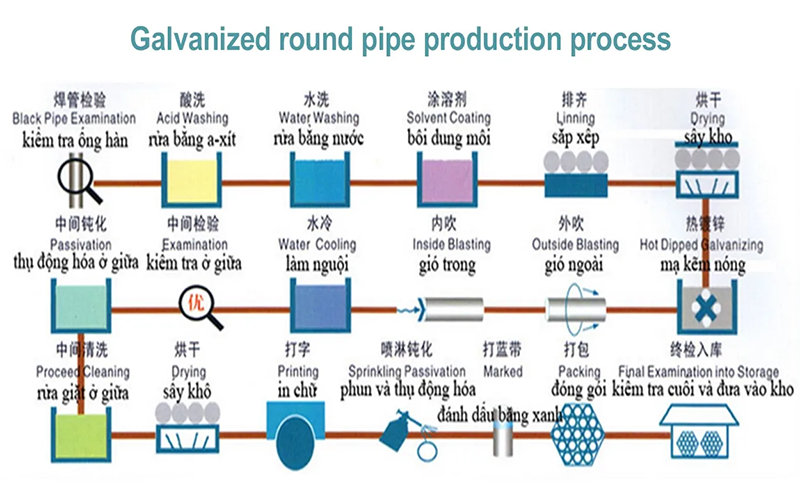

Procédé de galvanisation à chaud :

Désengraissage du pièce → lavage → lessivage → lavage → séchage trempage dans le solvant flux préchauffé galvanisé à chaud → refroidissement → finition → rinçage → séchage → test de passivation

Procédé de galvanisation à froid :

Désengraissage chimique → lavage → électrolyse au zinc à l'eau chaude → lavage → lavage → galvanisation au zinc corrosif sur acier → lavage → lavage → léger → → lavage → séchage passivation

Les avantages des tubes galvanisés sont les suivants :

Tout d'abord, le tube galvanisé après avoir subi une galvanisation par trempage chaud peut être protégé, et à l'intérieur de la cavité du tube ou dans tout autre endroit où aucun autre revêtement ne peut pénétrer facilement, le zinc peut couvrir entièrement, protégeant ainsi tout le tube galvanisé.

Deuxièmement, après avoir été galvanisé, le tuyau en acier galvanisé présente de très bonnes propriétés de résistance aux chocs et à l'usure, car la dureté du revêtement en zinc est supérieure à la dureté de l'acier, et donc sa résistance aux chocs et à l'abrasion après galvanisation par immersion est assez bonne. De plus, l'avantage principal de la galvanisation est que la couche de zinc dans les coins sera relativement épaisse avec une bonne résistance à l'abrasion et une bonne ductilité, tandis que d'autres revêtements sont souvent les plus minces et les plus difficiles à appliquer dans ces coins, ce qui les rend vulnérables aux dommages.

Spécifications:

| description | l Tuyau soudé galvanisé | |

| l Classe d'acier | l Astm a53 Gr.B / ASTM A106 | |

| l Norme | l ASTM A106/A106M;ASTM A53/A53M;API 5L;GB/T 8163-2008;GB/T 8162-2008;BS1387, BS1139,EN39, EN1139, ASTM A53, JIS G3444 | |

| l Matériau | l A106 Grade A,A106 Grade B,A106 Grade C,A53 Grade A,A53 Grade B,API 5L Grade B,10#,20#,45# | |

| l Surface | l Galvanisation par immersion à chaud; Galvanisation électrolytique; Méthode demandée par le client | |

| le Type | l 1. Pré-peint (zinc : 60-120G/M2) l 2. Galvanisé à chaud (zinc : 120-500G/M2) l 3. Galvanisé à froid (zinc : 10-50G/M2) | |

| taille L | l Épaisseur des murs | l 1-22mm |

| Diamètre extérieur | 21,3mm-610mm | |

| l Délai de livraison | l Livraison rapide ou selon la quantité commandée. | |

| l Emballage | l Emballage standard pour l'exportation adapté à la mer, ou selon les exigences. | |

| l Application | le transport de fluides ; le soutien structurel ; le chauffage, la ventilation et la climatisation (HVAC) ; l'industrie pétrolière et gazière ; l'équipement industriel | |

| contact | si vous avez des questions, n'hésitez pas à me contacter. | |

| taille du conteneur | conteneur 20ft GP : 5898mm (Longueur) x 2352mm (Largeur) x 2393mm (Hauteur) 24-26CBMl l Conteneur 40ft GP : 12032mm (Longueur) x 2352mm (Largeur) x 2393mm (Hauteur) 54CBMl l Conteneur 40ft HC : 12032mm (Longueur) x 2352mm (Largeur) x 2698mm (Hauteur) 68CBM |

|

Détail rapide :

1. tube gi, tube rond en acier galvanisé par immersion à chaud, tube en acier galvanisé, tube soudé en acier gi

2. Tube rond en acier galvanisé par immersion à chaud (HDG), est largement utilisé dans divers secteurs industriels et de construction dans le monde entier.

Le tube en acier galvanisé froid est électrogalvanisé, la quantité de galvanisation est très faible, seulement 10-50g/m2, sa résistance à la corrosion est bien inférieure à celle du tube en acier galvanisé à chaud.

Il peut être utilisé dans la construction, les machines, les mines de charbon, l'industrie chimique, l'électricité, les véhicules ferroviaires, l'industrie automobile, les routes, les ponts, les conteneurs, les installations sportives, les machines agricoles, les machines pétrolières, les machines de prospection et d'autres industries manufacturières.

| Propriétés chimiques % | |||||||||

| Classe A | |||||||||

| C | Mn | P | S | Oui | Cr | Cu | Mo | Ni | V. Le groupe |

| 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Classe B | |||||||||

| C | Mn | P | S | Oui | Cr | Cu | Mo | Ni | V. Le groupe |

| 0.3 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Classe C | |||||||||

| C | Mn | P | S | Oui | Cr | Cu | Mo | Ni | V. Le groupe |

| 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Propriétés mécaniques | |||

| Classe A | Classe B | Classe C | |

| Résistance à la traction | 330 | 415 | 485 |

| Résistance à la traction | 205 | 240 | 275 |

Description :

Le tube soudé galvanisé désigne un type de tube en acier recouvert d'une couche de zinc par un procédé appelé galvanisation.

Le procédé de galvanisation consiste à immerger le tube en acier dans un bain de zinc fondu, ce qui forme une couche protectrice sur la surface du tube.

Le but de la galvanisation des tubes soudés est de fournir une résistance à la corrosion et d'allonger la durée de vie du tube. La couche de zinc agit comme une barrière entre l'acier et l'environnement environnant, protégeant le tube de la rouille et d'autres formes de corrosion.

Cela rend les tubes soudés galvanisés adaptés à diverses applications, en particulier dans les industries où l'exposition à l'humidité ou aux substances corrosives est fréquente.

Parmi les principaux avantages des tubes soudés galvanisés, on peut citer :

1. Résistance à la corrosion : l'enrobage en zinc offre une excellente résistance à la corrosion, ce qui rend les tubes galvanisés adaptés pour les applications en extérieur et souterraines.

2. Durabilité : la combinaison d'acier et d'enrobage en zinc améliore la solidité et la durabilité du tube, lui permettant de

résister à des conditions difficiles et à un usage intensif.

3. Coût avantageux : les tubes soudés galvanisés sont généralement plus abordables par rapport aux autres alternatives résistantes à la corrosion, ce qui en fait un choix économique pour divers projets.

4. Installation facile : les tubes soudés galvanisés sont relativement faciles à installer grâce à leurs dimensions standardisées et leur compatibilité

avec les raccords et connecteurs couramment utilisés.

5. Polyvalence : les tubes soudés galvanisés sont disponibles en différentes tailles et épaisseurs, les rendant adaptés à une large gamme d'applications, y compris la plomberie, la construction, l'agriculture et les projets industriels.

Il est important de noter que les tubes soudés galvanisés ont des limitations. Avec le temps, l'enrobage en zinc peut se dégrader ou s'user,

notamment dans des environnements très corrosifs. Par conséquent, des inspections et maintenances régulières sont nécessaires pour garantir la protection continue du tube.

De plus, lorsqu'on travaille avec des tubes soudés galvanisés, il est important de prendre les précautions de sécurité appropriées, telles que l'utilisation de

l'équipement de protection individuelle adéquat et la ventilation appropriée, car le processus de galvanisation peut libérer des fumées qui peuvent être nocives si inhalées.

Applications :

construction, machinerie, mines de charbon, industrie chimique, électricité, véhicules ferroviaires, industrie automobile, routes, ponts, conteneurs, installations sportives, machines agricoles, machines pétrolières, machines de prospection et autres industries manufacturières.

Spécifications :

| Tube d'Acier Galvanisé Rond | |||||||||

| Norme : API 5L, API 5CT, ASTM A53, ASTM A500, GB9711.1 Application : À utiliser pour transporter du gaz, de l'eau et du pétrole dans les industries pétrolières et du gaz naturel et utilisez à des fins de tubes en acier structurel. Grade principal du tube en acier : GR.A, GR.B, GR.C, Q195, Q235B, Q345B et autres. |

|||||||||

| Pouce | Diamètre extérieur (mm) | Épaisseur standard du mur | |||||||

| SCH 10WT (mm) | SCH 20WT (mm) | SCH 40WT (mm) | SCH 60WT (mm) | SCH 80WT (mm) | SCH 100WT (mm) | SCH 160WT (mm) | XXS (mm) | ||

| 1/4” | 13.7 | 2.24 | 3.02 | ||||||

| 3/8” | 17.1 | 2.31 | 3.2 | ||||||

| 1/2” | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.5 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.7 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.7 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

| 30" | 762 | 7.92 | 12.7 | ||||||

| 32" | 813 | 7.92 | 12.7 | 17.48 | |||||

| 34" | 863 | 7.92 | 12.7 | 17.48 | |||||

| 36" | 914 | 7.92 | 12.7 | 19.05 | |||||

| 38" | 965 | ||||||||

| 40" | 1016 | ||||||||

| 42" | 1066 | ||||||||

| 44" | 1117 | ||||||||

| 46" | 1168 | ||||||||

| 48" | 1219 | ||||||||

Avantage concurrentiel :

Nous disposons d'un avantage compétitif en termes de prix et de délais de livraison dans l'approvisionnement en tubes d'acier sans soudure, non seulement pour les clients volumiques, mais nous acceptons également les commandes personnalisées des clients concernant les échantillons, les conceptions, les spécifications et les exigences en matière d'emballage.

Notre équipe aimable aimerait vous entendre!