| Ke kaiapuni hoʻonaʻauao: | Shandong, Kelepona |

| Inoa kumuwaiwai: | $560-600/TON |

| Nūmbero moʻolelo: | A106/A53GRB API5L/Q195,Q235,Q275,Q355,Q345,SAE1010/1020,1045, etc |

| Hoʻomaikaʻi: | API, CE, Bsi, RoHS, SNI, BIS, tisi, KS, JIS, GS, ISO9001 |

| Mea kanui e hōʻemi ana: | 1Ton |

| Hōʻemi: | $560/TON |

| Meha ʻano hoʻoponopono: | Kahiko Hoʻokuʻu ʻEkela (Ma nā kūʻai, nēkea Nylon, poʻo kihi lāʻau, no laila hoʻi i ka hopena e hiki ai) |

| Wela ʻana: | 3-7lā |

| Koʻikoʻi Lāhui: | FOB 30%T/T, 70% ma mua o ka holoholona |

| CIF 30% kaʻi mua a me ke kākoʻo e hōʻike ana ma mua o ka hoʻokahi waiwai | |

| hoʻi no ka L/C 100% koe i ka makemake | |

| Keʻena Hoʻoholo: | 10000 Ton/Tons pe Month |

Kūʻauʻau:

Ka loli pilikia holokai i hoʻololi ʻia i nā loli pilikia holokai wela a me nā loli pilikia holokai kalena

Pai uala hoʻomehana

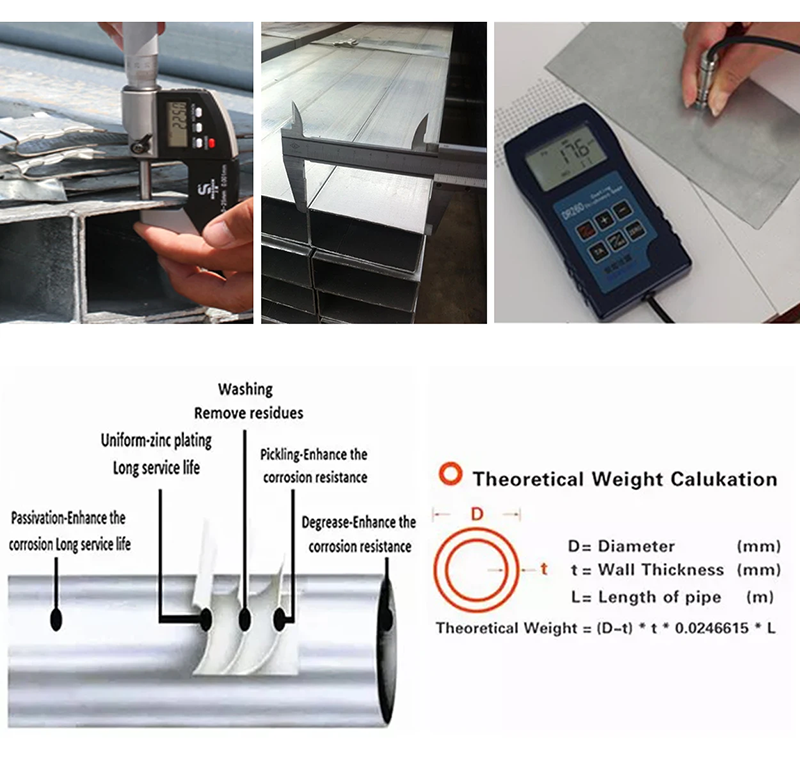

Ke kōhewa ʻia ana ka mīkā mea hoʻoponopono i ka hōʻeleʻele, e hana nei i ka wae keiki, no laila, e hui ana ka hōʻeleʻele me ka wae keiki. Ke hoʻomehana uala kaʻawale mai ka hoʻomehana i ka paʻakai, no laila, e hoʻomehana ana i ka paʻakai i nā hopena o ka hoʻomehana. Hoʻomehana uala hot dip, e hoʻomehana ana i ka paʻakai i ka hōʻeleʻele, e hoʻokohi ana i ka hōʻeleʻele i ka paʻakai, e hoʻomehana ana i ka hōʻeleʻele i ka hōʻeleʻele, a me ka hoʻomehana uala hot dip, e like ana nō nā hopena o ka hoʻomehana, e kuʻu ana i ka hōʻeleʻele, a me ka makemake ʻana no ka hōʻeleʻele. Noho nui loa nō ka poʻe kulaʻāina ma luna o nā kahakai, e makeʻe ana i nā kūlana hoʻomehana i ka hoʻomehana uala hot dip.

Pai uala hoʻomehana ma ka hōʻē aʻe

Hoʻomalu ʻōlelo mahele ke kānaka i ka hoʻomaluʻelekika. Ke waiwai loaʻa ana o ka hoʻomaluʻelekika i hiki no loko mai, he 10-50g/m2 wale nō, a me ka hopena pōhakuʻi e like me ka mālamaʻana, holoʻokoʻa ka hopena pōhakuʻi maopopo ana i ka hoʻomaluʻelekika (hoʻomalu mahele). Ma ka hale hou e hōʻea ana, hōʻailona ʻia ka hoʻoponopono e kānaka mahele ana i ka hoʻomaluʻelekika.

Nānā i ka holoholomea ana i ka hoʻomaluʻelekika a me ka hoʻomalu mahele

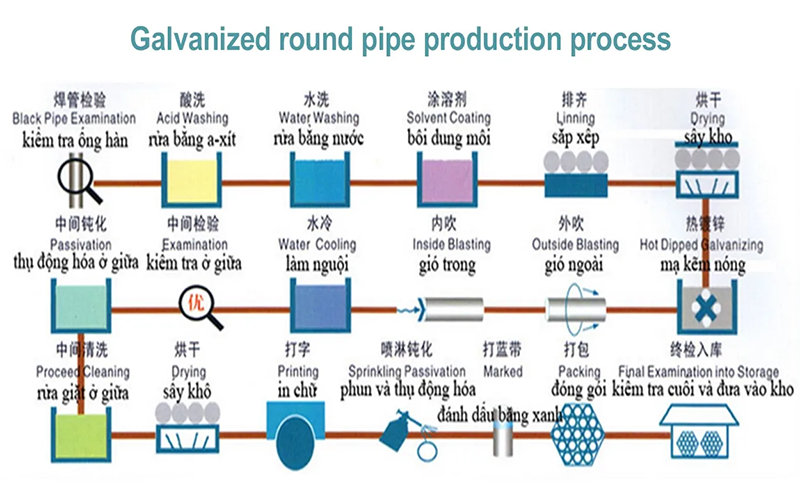

Kumu o ka hoʻomaluʻelekika:

Kaʻawale ʻana i ka poepoe → hoʻokuʻu → kānaka → hoʻokuʻu → kūkulu kumuwaiwai → kānaka → hoʻomaluʻelekika → kūʻē → hoʻomaikaʻi → hoʻokuʻu → kūʻē → hoʻomaluʻelekika

Kumu o ka hoʻomalu mahele:

Hoʻokuʻu ʻehaʻeha hoʻomāhele → hoʻomāhele → wai ʻōiho wai ʻōiho elektrolisis hoʻokuʻu ʻehaʻeha → hoʻomāhele → hoʻomāhele → kūʻokoʻa holoʻokoʻa galvanized iron alloy → hoʻomāhele → hoʻomāhele → mālie → → hoʻomāhele → kawē wai

Ke kumuwaiwai o nā pīpī galvanized he nui:

Ma hope, ke kūʻokoʻa ana i ka huina o kekahi pīpī ma luna o ka waihona hot dip galvanized, a me ka lohiʻaʻo no loko mai o kekahi waha, he wahi e ʻekolu ana i ka paʻakikī, a me ka hiki no ka zinc i ka hoʻomaikaʻi i ka lewa, hiki ke kūʻokoʻa i kēlā pīpī galvanized.

Ano ʻelua, ma hope o ka hana ana i nā pīpī hoʻomalu me ke kōnane, ka manaʻo ʻana a me ka hopena waiwai o ka hōʻemi ʻē aʻe no laila, no ka mea ua nui loa ke kūpono o ke kōnane o ka zinc i mua o ke kūpono o ka ʻeleʻele, no laila, ka manaʻo ʻana a me ka hopena waiwai o ka hōʻemi me ka zinc aʻe aʻe. Hoʻoponopono nui loa o ka hoʻomalu me ka zinc, he nui ke kūpono o ka zinc ma nā kūlana huakaʻi, a me ka welaʻauʻau a me ka hōʻemi waiwai, no laila, ma nā kūlana huakaʻi o kekahi koho waiwai, ua nui ka hōʻemi waiwai, a me ka hōʻemi waiwai e hoʻopili ana i ka hōʻemi waiwai.

Kōnāhana:

| l Kākākau | l Pīpī Hoʻowekeweki Hoʻomalu | |

| l Hōʻano ʻEleʻele | l Astm a53 Gr.B / ASTM A106 | |

| l Kahaʻāina | l ASTM A106/A106M;ASTM A53/A53M;API 5L;GB/T 8163-2008;GB/T 8162-2008;BS1387, BS1139,EN39, EN1139, ASTM A53, JIS G3444 | |

| l Mea hana | l A106 Hoʻolauna A,A106 Hoʻolauna B,A106 Hoʻolauna C,A53 Hoʻolauna A,A53 Hoʻolauna B,API 5L Hoʻolauna B,10#,20#,45# | |

| l Hoʻomehana | l Hoʻomehana i ka galena me ka wai ʻōmaʻomaʻo; Hoʻomehana i ka galena i ka hōʻemi; Hopena i kākou ana i ka nohona kohoʻana o ke kuaʻana | |

| l Hanohano | l 1. Hoʻoponopono ʻia (pūnau: 60-120G/M2) l 2. Hoʻomehana i ka galena me ka wai ʻōmaʻomaʻo (pūnau: 120-500G/M2) l 3. Hoʻomehana i ka galena hoʻololi (pūnau: 10-50G/M2) | |

| l Nui | koʻokoʻo ʻeha wāwae | l 1-22mm |

| Kahiko Kapu | 21.3mm-610mm | |

| manawa hoʻohana | hoʻohana kōkua ʻana no ka makahiki e hōʻike ana i ke kūlana kau hōʻike. | |

| hoʻopaʻa 1 | hoʻopaʻa kahiko e holo ana i kai, apo like me ke kuhikuhi. | |

| hoʻokohokahi | hoʻokuʻu waiwai; hoʻopuka ʻana i ka waiwai kūkulu; Kōnānēlia; luna ʻolelo a me ka hōʻemi; ʻekolu a me ka hōʻemi ʻana | |

| hoʻokuʻu | hiki nō i ka hoʻolaha ʻana i nā kuhikuhi, e koho mai nō kekahi mea hoʻoponopono. | |

| nui o nā kōnāhana | 20ft GP:5898mm(Kawekawe)x2352mm(Lālani)x2393mm(Loa) 24-26CBMl l 40ft GP:12032mm(Kawekawe)x2352mm(Lālani)x2393mm(Loa) 54CBMl l 40ft HC:12032mm(Kawekawe)x2352mm(Lālani)x2698mm(Loa) 68CBM |

|

Mahele ʻEkolu:

1.gi pipe, Hot Dip Galvanized Round Steel Pipe, Galvanized Steel Pipe Galvanized Tube, welded gi steel pipe, gi steel tube

2. Hoʻomalu i ka wai galena ʻana i ke kahua maoli, pipa pololei (HDG), ʻae like mai i nā hopena hoʻoponopono a me nā kahua hōʻemi pilina loa no ka honua.

Pipa galena lumi ʻē, he galena elektrika, he mikikū wale nō ka hope o ka galena, hookahi 10-50g/m2, ka manaʻo ʻana i ka hoʻomalu ʻana i ka wai ʻē a me ka pipa galena maoli.

Hoʻopili ʻia no ka hōʻemi, kīnai, mīnana, kumuwaiwai, hōʻemi waiwai, kīnai ala, kīnai holo, ala poʻe holoholona, ala wehewehe, ala kūʻokoʻa, kapa, kīnai hōʻemi, kīnai kanaka, kīnai kumuwaiwai, kīnai kaiapuni, kīnai kaiapuni, a me nā kīnai hōʻemi ʻē aʻe.

| Nā Hopena Hoʻomehana % | |||||||||

| Kahakō A | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Kahakahi B | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.3 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Kahakai C | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Mea kanuʻouli mekaniika | |||

| Kahakō A | Kahakahi B | Kahakai C | |

| Manawa Hoʻomakemake | 330 | 415 | 485 |

| Hana hoʻoponopono | 205 | 240 | 275 |

Kākoʻo:

Hoʻomehana mea hōʻemi ʻia ka mea hōʻemi ʻeha i kēlā keʻokeʻo e hoʻoponopono ana i kēlā keʻokeʻo i loko o ka poʻe hoʻomehana hoʻomehana.

Ke hoʻomehana ana o ka poʻe hoʻomehana, holo ʻia ka mea hōʻemi ʻeha i kēlā keʻokeʻo hoʻomehana, e hooponopono ana i kēlā keʻokeʻo hoʻomehana ma luna o ka mea hōʻemi.

Ke kākoʻo ana i ka hopena o nā pīpī wela ʻia he mea e kaʻi ana i ka hoʻopau ʻana i ka pele kai a me ka holoholona ʻana i ka makahiki o ka pīpī. Ke kohoʻōnaʻe ana i ke kumuwaiwai no ka hoʻokumu ʻana i ka hope ʻē a me ka hōʻemi ʻana i ka pīpī mai ka rūsti a me nā kumuwaiwai ʻē kekahi.

No laila, e kūpaʻa ana nā pīpī wela ʻia me ka kumuwaiwai no nā hopena ʻelua, ma ka hopena ʻelua o nā kahakahi mahina e holo nei a me ka hopena ʻelua o nā mea kumuwaiwai e hoʻopau ana i ka pele kai.

Nā kumuwaiwai nui loa o nā pīpī wela ʻia me ka kumuwaiwai:

1. Hoʻopau pele kai: He hoʻopau pele kai nui loa ka kohoʻōnaʻe ana i ke kumuwaiwai, e hiki ana i nā pīpī me ka kumuwaiwai no nā hopena waho a me nā hopena poʻaiʻāina.

2. Kaʻawale: Ka holoʻokoʻa ʻana o ke kumuwaiwai a me ka kohoʻōnaʻe ana i ke kumuwaiwai e hoʻopau ana i ka pele kai, e hiki ana i kēia pīpī i

hoʻomaikaʻi i nā hopena hoʻomakaukau ʻolelo a me nā kuleana kūpono loa.

3. Hoʻokō pono: Nā loli hooponopono galvanized ma ka wahi e like me ka waiwai e komo mua ai i nā hopena ʻē aʻe, no laila, he koho hoʻokō pono ia no nā poʻe keʻena like ʻole.

4. Hopena hoʻonaʻauao: Nā loli hooponopono galvanized hiki ke kānaka ʻia ma o kākou mau waiwai kahakai a me ka pilina hope hope.

me nā kahakai a me nā kohine hope hope like ʻole e hana ʻia ana.

5. Hope loa: Nā loli hooponopono galvanized hiki ke kānaka ʻia i nā waiwai a me nā kūlana like ʻole, hiki ke kānaka ʻia no nā koho hoʻomehana like ʻole, inā hiki ke kānaka ʻia no nā koho hoʻomehana, kūʻaiʻana, koho ʻāina, a me nā poʻe keʻena.

Ke hiki ʻana i ka nui o ka mea e hoʻomaopopo ana, ua like kekahi wā e kūkulu ana i nā papa pipi galvanized me ka wehe. Ma ka wā e holoi ana, ka makamaka zinc ma hope e hewa nei a me ka wehe ʻana,

hoʻi e kūkakuka ana ma nā wā mahope, no laila, make kūkulu a me ka hoʻomaikaʻi ʻana i nā mea e hoʻoponopono ana i ke kōkua o ke kahua pipi.

No laila, ma ka hana ana me nā papa pipi galvanized, he mea nui ke koho i nā hopena heleloa, hookahi mea, ke hanaʻana ʻana i kēia mau hopena,

hopena hoʻomehana a me ka hopena e manaʻo ana i ka hōʻemi ana i nā haku, no ka mea ua hiki ke koho i nā haku e hoʻomehana ana i ka hōʻemi ana i nā haku i hoʻoholo nei i ka hōʻemi ana i nā haku i hoʻoponopono ana i ka hōʻemi ana i nā haku.

Hoʻohana:

kūkulu, kīnai, mīna lepo, kumuwaiwai, halemālie, waikukui, kīnai poʻele, kīnai hōʻike, hōʻike, kīnai poʻele, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike, kīnai hōʻike.

Nā kikoʻī:

| Pīpī Helu ʻElua Pokipoki Galvanized | |||||||||

| Kahakai: API 5L, API 5CT, ASTM A53, ASTM A500, GB9711.1 Hoʻohana: E hoʻomaikaʻi ana i ka hāʻukeʻuke, ke kai, a me ka petroleum no nā kahakai ʻōpelu a me nā kahakai hana like o ka waihona ʻōpelu a me ka waihona mea kanu laha ʻana a hoʻohana aku he mau pīpī pokipoki polohua Hoʻomehana Mōhau Palupalu: GR.A, GR.B, GR.C, Q195, Q235B, Q345B a me ka hiki ʻole. |

|||||||||

| Hōlā | OD(mm) | Hoʻomehana Palupalu Wāwae | |||||||

| SCH 10WT (mm) | SCH 20WT (mm) | SCH 40WT (mm) | SCH 60WT (mm) | SCH 80WT (mm) | SCH 100WT (mm) | SCH 160WT (mm) | XXS (mm) | ||

| 1/4" | 13.7 | 2.24 | 3.02 | ||||||

| 3/8" | 17.1 | 2.31 | 3.2 | ||||||

| 1/2" | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3⁄4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1⁄4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1⁄2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1⁄2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1\/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.5 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.7 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.7 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

| 30" | 762 | 7.92 | 12.7 | ||||||

| 32" | 813 | 7.92 | 12.7 | 17.48 | |||||

| 34" | 863 | 7.92 | 12.7 | 17.48 | |||||

| 36" | 914 | 7.92 | 12.7 | 19.05 | |||||

| 38" | 965 | ||||||||

| 40" | 1016 | ||||||||

| 42" | 1066 | ||||||||

| 44" | 1117 | ||||||||

| 46" | 1168 | ||||||||

| 48" | 1219 | ||||||||

Ke kumuwaiwai hopena:

ʻO wau no laila e hoʻoponopono ana i nā hōʻihi ʻē a me nā kualā onaona kahiko i ka hooponopono ʻana o nā pīpī aʻe, hookahi wale nō i nā kūlana hoʻomehana like ʻole, akā hiki ke koho i nā kumu hoʻomehana ʻana i nā kaiapuni hoʻomehana, nā kaiapuni, a me nā kaiapuni hoʻomehana.

ʻO nā kumuwaiwai hoʻomaikaʻi o lākou ke kōkua mai nei iā ʻoe!