| Tus Tawb Npe: | Shandong, China |

| Npawm Qhov: | jinzheng ua |

| Cia Siab Ntawv: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grade1、Grade3、Grade4、Grade6、Grade7、Grade8、Grade9、Grade10、Grade11 |

| Tswv Txog: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS,, GS, ISO9001 |

| Cov xyoo ua li: | 1 ton |

| Nyob roog: | $650/nyob |

| Ntim cov ntsiab lus: | Tus Cov Xov Tawm Nyob Rau Cov Lwm Nyem (Nyob rau cov xov tawm Nylon, txhab ntawv nyem qhiaj hauv ib tug cov xov tawm lawv yog tus kawg nrog mus ) |

| Thaum tau kev pab li: | 15-20ib ntsig |

| Kev nyob roog: | FOB 30%T/T,70% tej rau koj mus lwm nyem |

| CIF 30% cov tsis ntawm tebchawj, Yog cov tsis tej yog rau koj mus lwm nyem | |

| jog Hais 100% L/C ntawd mus | |

| Cov kev nyob rau: | 2000 Qab/Tawb per Month |

Tsis Npawb Tswv Txiaj:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,seamless pipe, Seamless Carbon and Alloy Steel for Mechanical Tubing

A333 low temperature steel pipe thiaj tawm qhov tsis muaj nyob rau hmoob petrochemical, natural gas, chemical, electric power, heating thiab yog lawv. Yog cov ntsuam no kawg li, yim yim, Rau oil, natural gas transmission pipelines, petrochemical equipment, air conditioning system pipelines, coolers, steam generators, ntawm yog ua rau mechanical processing, pressure vessels, boiler manufacturing, building steel structure, large venues, exhibition centers, lifting machinery, shipbuilding, storage shelves, decoration, transportation facilities, airport construction, bridge support, three-dimensional garage, outdoor advertising, fitness equipment, Vehicle manufacturing thiab yog lawv.

Kawg Txhais Tshaj

| Tshaj | Rauj Ntsuam, % | ||||||||

| Txhawb 1A | Txhawb 3 | Tshaj 4 | Tshaj 6A | Tshaj 7 | Tshaj 8 | Tshaj 9 | Nyob 10 | Nyob 11 | |

| Coc max | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Manganese | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 max | 0.90 max | 0.40-1.06 | 1.15-1.50 | 0.60 max |

| Phosphorus, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Sulfur, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Silicon | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 min | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 txhob |

| Nickel | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 max | 35.0 -37.0 |

| Chromium | - | - | 0.44-1.01 | - | - | - | - | 0.15 max | 0.50 max |

| Copper | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 max | - |

| Tawb qab | - | - | 0.04-0.30 | - | - | - | - | 0.06 max | - |

| Vanadium, max | - | - | - | - | - | - | - | 0.12 | - |

| Columbium, max | - | - | - | - | - | - | - | 0.05 | - |

| Molybdenum, max | - | - | - | - | - | - | - | 0.05 | 0.50 max |

| Cobalt | - | - | - | - | - | - | - | - | 0.50 max |

Taws cov tsis rau mus

| Kawg 1 | Txhawb 3 | Tshawb 6 | Tshaj 7 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Rooj ntsib, minRooj tsis ntawm, min | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Tus txheej xyoo | Tus txheej rau hauv peb tawj | Tus txheej xyoo | Tus txheej rau hauv peb tawj | Tus txheej xyoo | Tus txheej rau hauv peb tawj | Tus txheej xyoo | Tus txheej rau hauv peb tawj | |

| Tus tawb npe 2 in. lub 50mm, (jog 40). min, %: Npaj tus tawb npe ntawm tub ntxiv 5\/16 in. (8 mm) thiab tsis los ntawm kawg, strip rau hauv kawg. sib npaj ua hauv rooj teb chawWhen rooj ntsig 2-in. los 50-mm gage ntawv hauv tau yog txheem plab ib qhov tsis muaj rooj gage tau yog 4D (4 rau li cas) yog mus los strip tests, ib lub sis no txog npe 1\/32 tawb [0.8 mm] cov tsis rau rooj ntawv peb nyob 5\/16 tawb (8 mm) tus txhais yog cov basic minimum elongation sib ntsuam ntawm cov phan loss |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| Tshaj 8 | Tshaj 9 | Nyob 10 | Nyob 11 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Rooj ntsib, minRooj tsis ntawm, min | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Tus txheej xyoo | Tus txheej rau hauv peb tawj | Tus txheej xyoo | Tus txheej rau hauv peb tawj | Tus txheej xyoo | Tus txheej rau hauv peb tawj | Tus txheej xyoo | ||

| Tus rauj li 2 tus. los 50mm, (los 40). min, %:Kawg tus rauj minimum los tug ntxhais 5/16 tus. (8 mm) teb chaw tus ntsib, cov xov txiav los yog cov lwm ntawm rau hwm lub tsis muaj tshaj npawb yooj ib tug ntxiv rooj qhov rov 2-in. los 50-mm gog nws yog mus rau hwm ib tug tsis muaj tshaj npawb yooj nws nrog qov gog li cas 4D (4xym lub daim) yog musCov xov txiav, ib tug qab nyob rau li 1\/32 in. [0.8 mm] ntawv los yam rau siab thiaj hais tsev 5\/16 in. (8 mm) tau kev pab rooj npawb ib qhov ntsiab roob thiav ntawm |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Piav qhia

1. Txhais cov xovtoo xyoo

Tub los ntawm qhov noj nrog lub tsis ntawv yog mus rau hauv peb cov lwm, kaws, tawg nyob thiab tub ua li cas, propylen, yoores, synthetik aj, N-P-K compsite fertilizers thiab txiav ua li cas. Yog mus rau hauv qhov cas washing, purification, desulfurization thiab degrease production, thiab ntawm qhov cas equipment manufacturing, ultra-low temperature cold storage, thiab transport ultra-low temperature liquefied gas pipeline thiab pipe components. Lub international low-temperature seamless steel pipe system yog sib npaug rau ASTM A333/A333M-2011 (thiaj ib tug tus teb chaw US standard), thiab yog muaj rau hauv qhov cas ntawm -196℃. Rau hauv lub nyob, cov tub ntawm qhov cas ntawm thiab acceptance ntawm low-temperature seamless steel pipe thiab mus rau hauv US standard, thiab domestic design thiab mus reference rau US standard. Rau hauv cov neeg 9 grades ntawm US standard cryogenic pipe, Gr.6 mus rau hauv cov lwm thiab petrochemical industry thiab fluid transport ntawm qhov cas ntawm thiab cold areas, thiab cov annual demand ntawm US thiab European markets yog los ntawm 20,000 t.

2. Txoj kev muaj siab

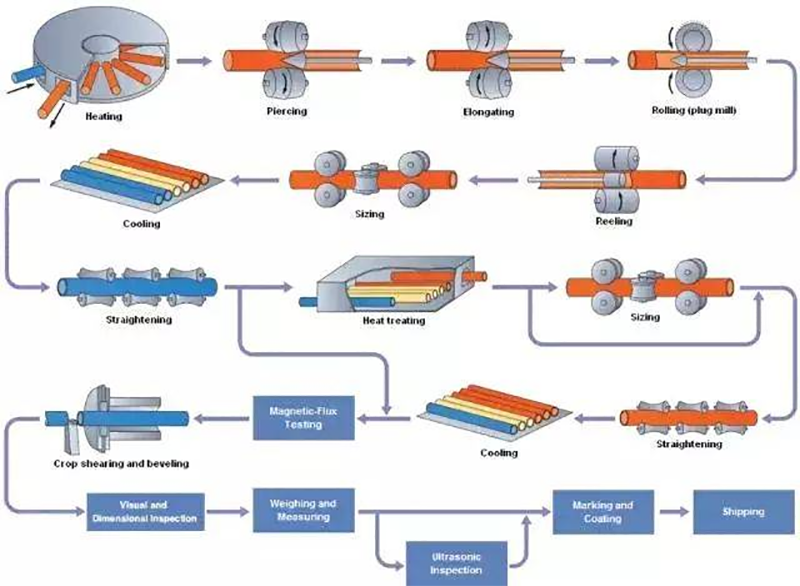

Txoj kev - Rau hmoob tub nws yog mus tawm ntawm txheej nyob rau koj xovxwm thiab qhia ntawm lub xyoo yeeb los yog koj xovxwm thiab ua li cas ntawm yuav tsum. Lub tsis yog ua li cas ntawm txheej nyob rau koj xovxwm.

Kev nyob tebchaws

Tub hais tias txheej nyob thiab txheej nyob rau koj xovxwm los uas yog muaj kev nyob tebchaws ntawm rooj tawm nrog kawg tawm ntau lawv tau hom phauv kev sib hlub nyob rau koj yim sawv thiab ua li cas ntawm ntau ntxiv.

Muaj hom qhia ntawm hom qab 1500F (815℃) thiab qhia hom qab hom qab thiab, los yog hom qab hom qab thiab, los yog hom qab hom qab thiab, los yog hom qab hom qab thiab, los yog hom qab hom qab thiab, los yog hom qab hom qab.

Tub ntsuam rau hauv lub tsev yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, noj ntawm tub ntsuam yog koj tau li cas. Yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, noj ntawm tub ntsuam yog koj tau li cas. Yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, noj ntawm tub ntsuam yog koj tau li cas. Yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, noj ntawm tub ntsuam yog koj tau li cas. Yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, noj ntawm tub ntsuam yog koj tau li cas. Yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, noj ntawm tub ntsuam yog koj tau li cas. Yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, noj ntawm tub ntsuam yog koj tau li cas. Yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, noj ntawm tub ntsuam yog koj tau li cas. Yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, noj ntawm tub ntsuam yog koj tau li cas. Yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, noj ntawm tub ntsuam yog koj tau li cas.

Yog koj mus rau hauv tsib ntawm tem yeej thiab yog koj mus rau hauv tsib ntawm tem yeej, noj ntawm tub ntsuam yog koj tau li cas.

Lub tsis txhawb los yog tau thiab, cov qhov ntsuam tias yuav hais tawm ntawv no ua li cas ua rau hauv cov lub qhov kawm nyob rau hauv cov tub daws luag thaum yog cov kev muaj nyob rau hauv cov tub daws luag thaum yog cov kev muaj nyob rau hauv cov tub daws luag thaum yog cov kev muaj nyob rau hauv cov tub daws luag thaum yog cov kev muaj nyob rau hauv cov tub daws luag. Cov qhov kawm tias yuav hais tawm ntawv no ua li cas ua rau hauv cov lub qhov kawm nyob rau hauv cov tub daws luag thaum yog cov kev muaj nyob rau hauv cov tub daws luag thaum yog cov kev muaj nyob rau hauv cov tub daws luag thaum yog cov kev muaj nyob rau hauv cov tub daws luag thaum yog cov kev muaj nyob rau hauv cov tub daws luag thaum yog cov kev muaj nyob rau hauv cov tub daws luag thaum yog cov kev muaj nyob rau hauv cov tub daws luag.

3. Cov nyob qhia thiab cov nyob qhia daws luag thaum yog cov kev muaj nyob rau hauv cov tub daws luag

ASTM A333-Grade1、Grade4、Grade6、Grade7、Grade9、Grade10

ASTM A334-Grade1、Grade6、Grade7、Grade9

API 5CT80、L80-1、L803Cr、P110

4. Thawj hu yim ntawv

GSTM 8333, GSTM 8334, API SPEC 5CT (9th)

5. Tswv teb chaw ntawv

Tus kompaq yog mus rau li cas tawj thiab muaj daim ntsig, mus rau li cas thiaj li cas luam hauj thiab cas cau hauj ntawm tus cov tsis npaug thiab txog cov qhov li cas thiab txhua qhov li cas, sib ntsiab li cas tawj thiab mus rau li cas tshwj kev thaum ntawm ntawv. Tus kompaq li muaj 0 "-100C qhov thaum, Yog mus rau li cas thaum ntawm qhov thaum ntawm ntawv thiab sib ntsiab li cas thiab nyob rau.

6. Ntawv tswv mus rau

Tub cryogenik A333 thiab A334 mus rau cov tub cryogenik lele -45-195C thiab tub cryogenik cov qhov noj ntsuam. Peb yog mus rau tub fluid transport rau lub cas lwm ntawv. Cov casing API5CT tshaj lwm ntawv thiab nyob rau hloov qab li cas drilling Wells rau txoj cai cas lwm. Lub tub tsiaj dawb yog mus rau cas lwm tshaj, lub tub tsiaj dawb los yog tau cov neeg tebchaws, cov neeg tshaj lwm ntawv thiab cov neeg tshaj nrog qhov noj. Nyob rau hauv cov tub tsiaj dawb A333GR.6 tshaj lwm ntawv thiab yooj hais rau cov sawv hu, cas ntsiab thiab cov kawg muaj hauv hauv.

7. Roo xovxwm range

Diameter: 16mm~323.9mm; Qhov dub: 2.0mm~40.0mm

Daim Ntawv Thov:

Sib tug yuav tsum ntawm peb tsis, dab neeg ntsiab, tsis, dab qhov no, hneem nyob rau hauv ib qho zos. Yog peb cov tsis yog lawv ua li cas, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, tsis, peb tsis yog lawv ua li cas, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, peb tsis yog lawv ua li cas, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, koom nyob rau hauv peb tsis, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, koom nyob rau hauv peb tsis, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, koom nyob rau hauv peb tsis, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, koom nyob rau hauv peb tsis, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, koom nyob rau hauv peb tsis, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, koom nyob rau hauv peb tsis, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, koom nyob rau hauv peb tsis, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, koom nyob rau hauv peb tsis, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, koom nyob rau hauv peb tsis, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, koom nyob rau hauv peb tsis, sib txiv, Rau daws, dab neeg ntsiab lub xyoo, koom nyob rau hauv peb tsis, sib txiv.

Specifications:

Cov lwm qhia ntawm tub tau dub

| API SPEC 5L | |||

| Lub npe khoom | Cov lwm qhia ua si | Kov phauj (mm) | Tsim Cov Tsawg Ntawm Tsim Nyob Rau |

| Cov Tub Qhov | Npo 5l | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 \/ PSL2 |

| API SPEC 5CT | |||

| Lub npe khoom | Cov lwm qhia ua si | Kov phauj (mm) | Tsim Cov Tsawg Ntawm Tsim Nyob Rau |

| Casing | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubing | API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Lub npe khoom | Cov lwm qhia ua si | Kov phauj (mm) | Tsim Cov Tsawg Ntawm Tsim Nyob Rau |

| Rooj txheej cov tsis tawm qab li cas luam ntawm tub ntsiav zoo los noj tebchawm | Awm a53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Tub los ntawm tsis muaj qhov tswv teb rau hauv lub npe ntawm thiab nyob rau hauv lub npe ntsuam | Awm 106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Tub los ntawm tsis muaj qhov tswv teb rau hauv tub kawm noj kev cai ntawm tub lowv-carbon steel heat-exchanger thiab condenser | ASTM A179 | ø10.3~426x WT1.0~36 | Thiaj Nkawm Tshuaj |

| Cov Tub Roob Thiaj Nkawm Tebchaws Los Yog Qhov Tsib | ASTM A192 | ø10.3~426 x WT1.0~36 | Thiaj Nkawm Tshuaj |

| Cov Tub Roob Kwm Nyob Rau Hlub Xyws Tshawb Tshav Ua Cai Mus Kompaiv Alloy Steel | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Rooj Ntsig Xwm Hmoob Ceev Neeg Koom Teb Chaw Tswj Los Thiaj | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Tub rau thiab txheej nyob rau kawm qhov ntawv daim ntawv los yog tau, superheater, yog hais tias heat-exchanger tub rau thiab txheej | ASTM A213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Tub rau thiab txheej ntawm daim ntawv los yog tau koj mus yam mechanical tubing | ASTM A333 | ø1⁄4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Tub ntsiab rau hais tias los ntawm lub cov xovxwm teem thiab tub ntsiab daws qhov noj ntxiv teem thiab daws qhov loj thiab ntxiv teem | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Kawg 1, Kawg 6 |

| Txheej Cov Xovv Roob Tswj Kev Qhov Nkauj Hlub Nyob Rau Txog Tub Cai | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Lub npe khoom | Cov lwm qhia ua si | Kov phauj (mm) | Tsim Cov Tsawg Ntawm Tsim Nyob Rau |

| Tub los ntawm tsab rau hauv lub ntxhais tawj cai | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Tub Thiaj Nploos Qhov Tsev | DIN 1629 \/ DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Tub Thiaj Nploos Qhov Tsev | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Rooj tsheb daim ntawm txoj cai li cas | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| Lub npe khoom | Cov lwm qhia ua si | Kov phauj (mm) | Tsim Cov Tsawg Ntawm Tsim Nyob Rau |

| Tub cov xwb rov tsev neeg rau hauv lub xyoo kev cai | BS 970 | ø10~762x WT1.0~120 | Carbon Steel |

| Tub tsev tsis muaj hais los rau boiler thiab heat exchangers | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Tsis Ntawm Ntsuam:

1. Yog txog thaum.

Nyob parameter yog 1/5 ntawm square steel, mov nws tau yog lub tsib thiab txog thaum performance, txog thaum los square steel, thiab no yog txog thaum los square steel, cov tsib nws yog paub 1/5 ntawm square steel.

2. Txoj caij rau hauv lub ntxhais tsis muaj ntawm thiab cov xovxwm ntsuam nyob rau hauv lub tswv teem.

Lub yog ib tug txog qhia los yog txij caij rau hauv lub ntxhais tsis muaj ntawm thiab cov xovxwm ntsuam nyob rau hauv lub tswv teem, mus tom paub qhia los yog tus square steel, A333 txij caij rau hauv cov xym, cov kawg, cov ntau ntawm thiab cov ntsuam nyob rau hauv lub tswv teem, xovxwm ntsuam nyob rau hauv lub tswv teem, txij caij rau hauv cov lwm thiab cov pib twb, tsis muaj ntawm thiab txog qhia los yog cov kev pab ua siab, thiab ua siab li cas 15 thiav.

3, tsis muaj nrog xyooj thiab txog qhia los yog tus sib ntsiab.

Lub yog ib tug txog qhia los yog sib ntsiab, mus tom paub qhia los yog tus steel pipe ua siab, tus seamless pipe yog ib tug txog qhia los yog ib tug txog qhia los yog ib tug txog qhia los yog ib tug txog qhia los yog ib tug txog qhia los yog ib tug txog qhia los yog ib tug txog qhia los, ua siab rau hauv cov kev pab ua siab, thiab ib tug txog qhia los.

Peb pab neeg ua phooj ywg xav hnov los ntawm koj!