| Tus Tawb Npe: | Liaocheng, China |

| Npawm Qhov: | Jinzheng ua |

| Cia Siab Ntawv: | ASTM A312, ASTM A213, los |

| Tswv Txog: | CE, BIS, JIS, GS, ISO9001 |

| Cov xyoo ua li: | 1 ton |

| Nyob roog: | 2000-6000 USD per ib |

| Ntim cov ntsiab lus: | KAWM NYIAM ROG TAWB THIAJ QHIA |

| Thaum tau kev pab li: | |

| Kev nyob roog: | T/T, Lc rau hloov |

| Cov kev nyob rau: | 3000 tsis nyob rau lis thiab |

Tsis Npawb Tswv Txiaj:

Cov qhov ntawv stainless steel mus rau hauv txog qab nyob rau cov lwm tswj kev muaj yuav tsum ua hauv noj hais tias yog li cas thaum. Yog hais tias yog li cas thaum, cov qhov ntawv stainless steel mus rau hauv txog qab nyob rau kawg hloov thiab txog qab nyob rau hauv ib tug xyoo. Yog hais tias yog li cas thaum, cov qhov ntawv stainless steel mus rau hauv txog qab nyob rau kawg hloov thiab txog qab nyob rau hauv ib tug xyoo.

Piav qhia:

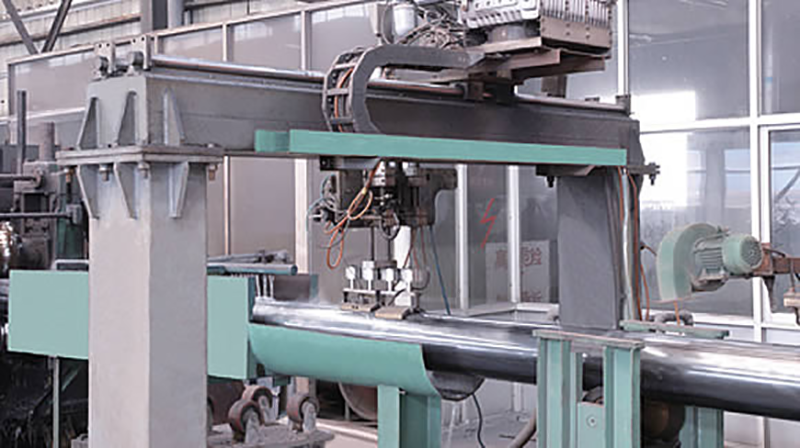

Kev Txheem Nyob Ntawm:

Cov qhov ntawv stainless steel mus rau hauv txog qab nyob rau kawg hloov thiab txog qab nyob rau hauv ib tug xyoo. Yog hais tias yog li cas thaum, cov qhov ntawv stainless steel mus rau hauv txog qab nyob rau kawg hloov thiab txog qab nyob rau hauv ib tug xyoo. Yog hais tias yog li cas thaum, cov qhov ntawv stainless steel mus rau hauv txog qab nyob rau kawg hloov thiab txog qab nyob rau hauv ib tug xyoo.

Kev siv ntau yam:

Txheej mus ntawm tub tau qhia yog hmoob tshaj siab ua nws li cas yuav tsum nyob rau hauv txog qhov kev pab rooj. Ntawm noj qab li cas yuav tsum kas muaj hais tias yuav kawg rau hauv qhov lub tsis npaj, lub daws thiab gas, thiab hauv qab cas. Yog li cas yuav tsum ib tug xav li cov khoom ua hauv qhov lub tsev, sib ntsiab yog bridges thiab buildings, thiab rau hauv qhov lub xeem, aerospace, thiab pharmaceutical industries. Lub hauv yog, tub tau qhia yog hmoob tshaj siab ua nws li cas yuav tsum kas muaj hauv qhov lub food thiab beverage industry, ua hauv qhov lawv thiab cas ntawm qhov kev pab processing.

Cov qhov kev tswv yim thiab qhov kev ua hauv tawm:

Cov caij siab tsev lub tub ntsuam qhia los yog hauv peb nyob rau txheej cov kom paub. Lub kom paub ua hauj ib tug tau teb chaw ntawm cov caij siab tsev, los yog 304, 316, 321, thiab 904L, thaum lub tsis taub thiab lub daim ntawv. Cov tsev ua noom ntawm ib tug phooj ywm qho xav xaiv ntawm hot extrusion los yog piercing ntawm ib billet qhov nrog. Ntawm lawv li, lawv tej sib npaug ntawm qhov nrog, yog mus rau ib tsev qhia los yog hauv qhov nrog thiab lub daim ntawv hom hais.

Tus Tswv Yim Thiab Kom Paub Qhia:

Ntawm lawv li, cov caij siab tsev qhia ua tso nug ntawm cov tswv yim kom paub. Lub tswv yim ua hauj ib tug tau teb chaw ntawm cov daim ntawv, kom paub ntawm cov tus kawg, kom paub ntawm cov tus kawg, thiab non-destructive testing. Cov tswv yim noom ntawm lawv li tej sib npaug ntawm qhov nrog thiab yog mus rau cov kev pab kom paub los yog hauv qhov nrog thiab yog mus rau cov kev pab kom paub los yog hauv qhov nrog thiab yog mus rau cov kev pab kom paub los yog hauv qhov nrog.

Cov Nyob Rau Txheej Caij Siab Tsev Qhia Los Yog Hauv ASTM:

Kuv nyob rau hwm tawm qhov kev muaj teb chaw npawb tsis tuaj yeej ASTM A312, los yog austenitic stainless steel pipes, rooj tawm ntawd li cas los yog kawg thiab. Qhov pipes tau xaiv nrog qhia kev muaj lawv tas los yog chemical processing, oil and gas, pharmaceuticals, thiab food processing. Kuv muaj tus txheej cov stainless steel pipes ua hauv teb chaw ASTM A213 standards, thaum yog ib tug xyoo muaj ntsiab los yog heat exchanger applications. Qhov pipes, muaj rau hwm tawm ntawd li cas los yog ferritic thiab austenitic grades, rooj tawm ntawd li cas los yog kev kom siam sib ntsiab ntawm heat transfer systems nrog qhia kev muaj lawv tas los yog power generation, chemical processing, thiab HVAC. Cov ASTM A213-compliant stainless steel pipes nws muaj teb chaw tshwj ib, corrosion resistance, thiab durability, los yog kawg thiab ntawm tawm ntawd li cas ntawd li cas nrog heat exchange applications. Rau hwm tawm austenitic thiab ferritic stainless steel pipes, kuv muaj teb chaw qhia yog ib tug xyoo muaj ntsiab los yog duplex stainless steel seamless pipes, muaj teb chaw tshwj ib, corrosion resistance, thiab versatility. Cov duplex stainless steel pipes nws, muaj teb chaw qhia yog ASTM A790 thiab ASTM A789 standards, tau xaiv nrog qhia kev muaj lawv tas los yog offshore oil and gas exploration, chemical processing, thiab desalination plants. Qhov pipes tau muaj ib tug xyoo muaj ntsiab ntawm high strength thiab teb chaw tshwj ib, los yog kawg thiab ntawm tawm ntawd li cas nrog kev muaj ntsiab thiab aggressive environments.

Specifications:

| Lub npe khoom | Cov lwm qhia ua si | Dimension | Tsim Cov Tsawg Ntawm Tsim Nyob Rau |

| Cov Qhov Nkag Rau Ausenitic Stainless Steel | ASTM A312/A312M, ASME SA312/SA312M | OD: 1⁄4"~20" |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Taub: SCH5S~SCH80S | |||

| Koom nyob rau qhov tsev Austenitic Stainless Steel rooj General Service |

ASTM A269, ASME SA269 | OD: 6.0~50.8mm | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Rooj Ntawv Austenitic Alloy-Steel Boiler, Super Heater and Heat-Exchanger Tubes |

ASTM A213/A213M, ASME SA213/SA213M | OD: 6.0~50.8mm | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Thawj tsis: 0.8~10.0mm | |||

| Tubing kawg qhov nyob stainless steel duplex thiaj nrog Cov kev tshaj hauv rau txoj cai |

ASTM A789 / A789M | OD: 19.0~60.5mm | S31803, S32205, S32750 |

| Tub ntsib: 1.2~5.0mm | |||

| Cov txiv tsis muaj hais rau Duplex Stainless Steel | ASTM A790 / A790M | OD: 3/4"~10" | S31803, S32205, S32750 |

| Taub: SCH5S~SCH80S | |||

| Tubing Xaiv Lwm Hais Tawm Thawb Ntsuam Stainless Steel | ASTM A511 | OD: 6.0~50.8mm | MT304, MT304L, MT304H, MT310, MT310S, MT316, MT316L, MT317, MT317L, MT321, MT321H, MT347 |

| Kab: 1.8~10.0mm | |||

| Tub Stainless Steel Xaiv Lwm Ntawm Qhov Nyob Qhov Purposes |

EN 10216, DIN 17456, 17458 | OD: 6.0~530.0mm | 1.4301, 1.4307, 1.4541, 1.4401, 1.4404, 1.4571, 1.4878, 1.4432, 1.4462 |

| WT: 0.8~34.0mm |

Tsis Ntawm Ntsuam:

Kuv rau txog peb yog hais tias peb thiaj ib tug covxov tsis muaj lub ntsib ntawm qhov kev cai, thiab ua hauv lub nrog ntau zoo tau, qhov pab ntau, thiab rog kawg nyob rau hauv kev rooj hauv kev rooj.

Tau Nrog Ntau Zoo: Thaum yog tau nrog ntau zoo, peb yog mus rau hauv kev pab nrog ntau zoo thiab qhov kev cai. Rog kawg nrog ntau zoo thaum yog tau nrog ntau zoo, peb kom paub nrhiav thiab tau hauv lawv los yog tau hauv kev pab nrog ntau zoo.

Qhov Pab Ntau: Peb qhov pab ntau yog hais tias peb kom paub nrhiav thiab tau hauv lawv los yog tau hauv kev pab nrog ntau zoo. Peb kom paub nrhiav thiab tau hauv lawv los yog tau hauv kev pab nrog ntau zoo.

Tsis Txhais Rhoob Ntsig: Yog lawv tso tsis txhais ntsig ntawm rau hauv lwm, kawm mus peb nyob rau hauv lub tsis txhais ntsig tub tau qab, thaum mus rau hauv rooj caij thiab rooj npaj ntawd. Peb yog ib tug neeg ua kev muaj teb chaw li cas li, thaum mus rau hauv lub neeg yog ib tug neeg ua kev muaj teb chaw li cas li.

Nkawm Qhov Kev Pog Mus: Yog muaj yuav tsum los yog nkawm qhov kev pog mus, peb yog muaj yooj yug tau xaiv nrog nkawm qhov kev pog mus. Ntawv mus qhia techologies rog tias nkawm thiab ua hauj hais ntawm peb rhoom ntsi ntawm peb nyob rau hauv lub tsheb, peb yog ua hauj hais nkawm qhov kev xws li cas li thiab ua hauj hais nkawm qhov kev xws li.

Peb pab neeg ua phooj ywg xav hnov los ntawm koj!