| Származási hely: | Shandong, Kína |

| Márkaneve: | $560-600/TÖN |

| Modell száma: | A106/A53GRB API5L/Q195,Q235,Q275,Q355,Q345/SAE1010/1020,1045, stb. |

| Tanúsítvány: | API, CE, Bsi, RoHS, SNI, BIS, tisi, KS, JIS, GS, ISO9001 |

| Minimális Megrendelési Mennyiség: | 1 tonna |

| Ár: | $560/TÖN |

| A csomagolás részletei: | Exportálási csomagolási szabvány (csomókban, nyilón zsákokban, fából készült tárolókban vagy a követelményeknek megfelelően) |

| Szállítási idő: | 3-7nap |

| Kifizetési feltételek: | FOB 30%-os T/T, 70% a küldés előtt |

| CIF 30%-os előre fizetés és a egyensúly a küldés elött fizetendő | |

| vagy Visszavonhatatlan 100%-os L/C látogató igény esetén | |

| Szállítási kapacitás: | 10000 Tonna/Hónap |

Leírás:

A galvanizált acélcsövet meleg galvanizált és hideg galvanizált acélcsövekre osztjuk

Cinkelt folyó

A fonalmetal reagál egy vasbázissal, amely egy ütőanyag réteget hoz létre, így összekapcsolja a bázist és a fedőréteget. A meleggalvanizálás során először savítják az acélcsövet, hogy eltávolítsák a vasoxidet az acélcsöv felszínéről, a savítás után ammoniumklorid vagy zincklorid vízibbollal, vagy ammoniumklorid-zincklorid vegyesvízibbollal mosogatják, majd beteszik a meleggalvanizáló thankba. A meleggalvanizálásnak vannak olyan előnyei, mint egyenletes fedés, erős rágcsálódás és hosszú hasznos élettartam. A északi folyamatok nagyrészt galvanizált símkötéket használnak, amely közvetlenül zsintről kavarodik.

Hűtött galvanizált cső

A hűtött galvanizálás az elektrogalvanizálás. A galvanizálás mennyisége nagyon kicsi, csak 10-50g/m², és a rostmentősége sokkal romább, mint a forrógalvanizált csöveké. A szabványos galvanizált csőgyártók többsége minőség biztosítása érdekében nem használnak elektrogalvanizálást (hűtött festészt). Csak a kis berendezéssel rendelkező és régi berendezésű kis cégek használják az elektrogalvanizált acégot, természetesen az árauk viszonylag olcsóbb. Az újonnan épített házakban tilos a hűtöttgalvanizált acélcsöveket vízmegszállítási csöveknek használni.

Forrógalvanizálás és hűtött galvanizálás különbsége

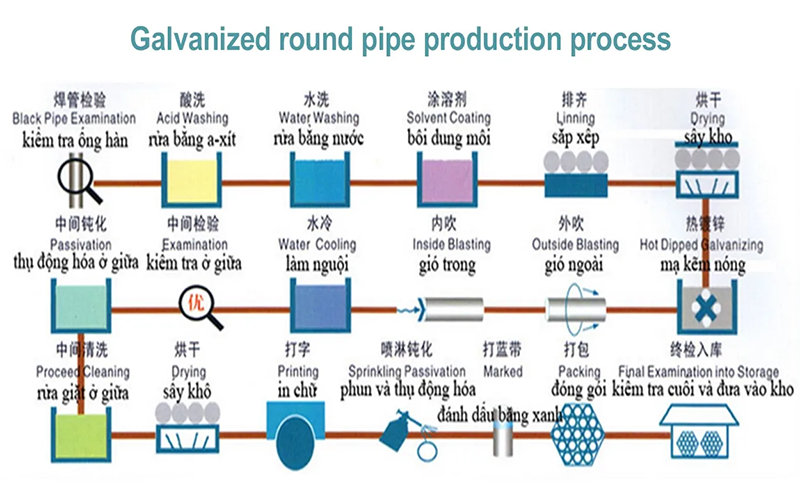

Forrógalvanizálási folyamat:

Munkaest törpölése → mosás → savasítás → mosás → szárítás szolvensbe merítés flúktorlódás előmelegített forrógalvanizálás → hűtés → befejezés → megmosás → szárítás → passziválás teszt

Hűtöttgalvanizálási folyamat:

Kémiai zsírleválasztás → mosás → forró víz forróvízi elektrolitikus zsírleválasztás → mosás → mosás → erős rostvédő cinkelt vas-ötvös → mosás → mosás → enyhe → → mosás → szárítás passziválás

A cinkelt csoborok előnyei az alábbiak:

Először is, a cinkelt cső a forráscinkelés után védelmet biztosít a felszínén, és a cső belső üregében vagy bármely más fedetben a sarok nehéz belépni, mélyebbre a cink könnyen elérheti a tetejét, így a teljes cinkelt cső védettséget nyer.

Másodszor, a cinkelt fémcsövet cinkelés után az impulzusellenállás és a keményítettsége nagyon jó, mivel a zénkötés a merevesség értéke nagyobb, mint a vas merevessége, így az impulzusellenállás és a súrlódási ellenállás is nagyon jó. A cinkelés legnagyobb előnye az, hogy a sarokokban a zénréteg viszonylag vastag és jó rugalmassággal és súrlódási ellenállással rendelkezik, míg más rétegek gyakran ezek a sarokok a legvastagabbak és a legnehezebb építésűek, így könnyen megsebesülhetnek.

Műszaki adatok:

| l Leírás | l Cinkelt összefonált cső | |

| l Vas típusa | l Astm a53 Gr.B / ASTM A106 | |

| l Szabvány | l ASTM A106/A106M;ASTM A53/A53M;API 5L;GB/T 8163-2008;GB/T 8162-2008;BS1387, BS1139,EN39, EN1139, ASTM A53, JIS G3444 | |

| l Anyag | l A106 Osztály A,A106 Osztály B,A106 Osztály C,A53 Osztály A,A53 Osztály B,API 5L Osztály B,10#,20#,45# | |

| l Felszín | l Hősárgálás; Elektrosárgálás; Ügyfél által kért módszer | |

| típus | l 1. Előre festett (zink: 60-120G/M2) l 2. Meleg zinkel galvanizált (zink: 120-500G/M2) l 3. Hideg zinkel galvanizált (zink: 10-50G/M2) | |

| l Méret | l Falvastagság | l 1-22mm |

| Külső átmérő | 21.3mm-610mm | |

| l Sikertáv | l Gyors szikertáv vagy a rendelt mennyiség szerint. | |

| l Csomagolás | l Szabványos exportálható tengeri csomagolás, vagy a követelményeknek megfelelően. | |

| l Alkalmazás | folyadékok átvitelése; szerkezeti támogatás; HVAC; olaj- és gázipar; ipari berendezések | |

| kapcsolat | ha bármilyen kérdés merül fel, kérjük, dobjon rám egy üzenetet. | |

| tartály mérete | 20 láb GP: 5898mm (Hossz) x 2352mm (Szélesség) x 2393mm (Magasság) 24-26CBMl l 40 láb GP: 12032mm (Hossz) x 2352mm (Szélesség) x 2393mm (Magasság) 54CBMl l 40 láb HC: 12032mm (Hossz) x 2352mm (Szélesség) x 2698mm (Magasság) 68CBM |

|

Gyors részletek:

1. gi cső, hősóvízzel galvanizált körű acélcső, galvanizált acélcső, galvanizált cső, összecsavarolt gi acélcső, gi acélcső

2. Hősóvízzel galvanizált körű acélcső (HDG), világszerte számos ipari és építési területen használatos.

A hideg galvanizált cső elektrón-galvanizált, a galvanizálási mennyiség nagyon kicsi, csak 10-50g/m2, saját korrozióellenállásának jelentős különbsége van a hősóvízzel galvanizált csővel.

Használható építészetben, gépjárműiparban, szénbányászatban, kémiai iparban, villamosenergiaban, vasúti járművekben, autóiparban, útin, híd, tároló, sportlétesítmények, mezőgazdasági gépek, olajgép, felfedezési gép és más gyártási iparágakban.

| Kémiai tulajdonságok % | |||||||||

| A osztály | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V. |

| 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| B osztály | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V. |

| 0.3 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| C osztály | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V. |

| 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Mechanikai tulajdonságok | |||

| A osztály | B osztály | C osztály | |

| Húzóerő | 330 | 415 | 485 |

| Nyomás erőteljesége | 205 | 240 | 275 |

Leírás:

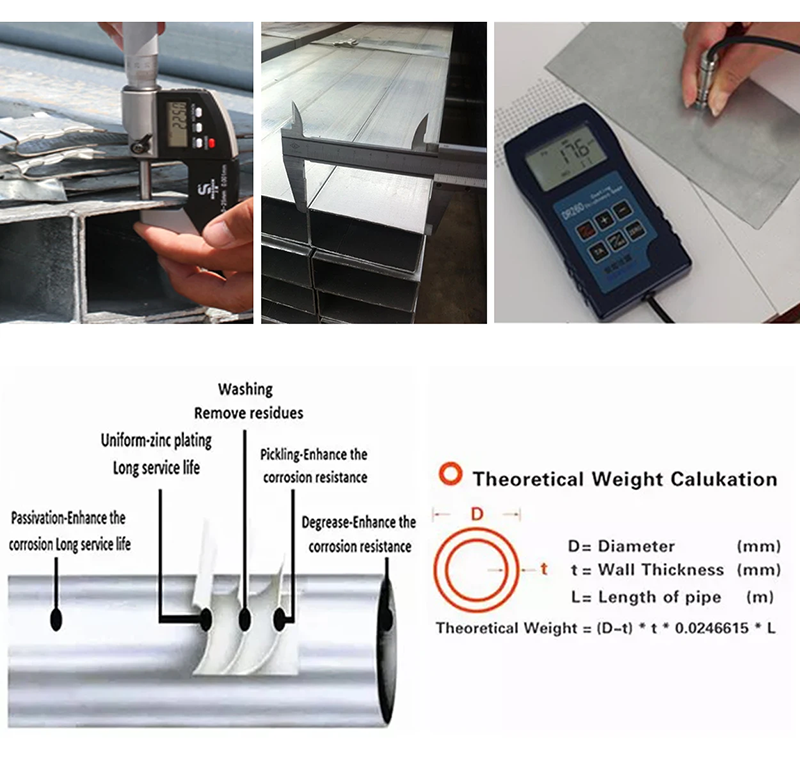

A galvanizált összeragasztott csövet azt a típusú acélcsövre vonatkoztatjuk, amelyet zinccoating-vel fednek el a galvanizálási folyamat során.

A galvanizálási folyamat abban áll, hogy az acélcsövet egy olyan forró zinckészletbe merítenek, amely egy védelmi réteget alkot a csövön.

A galvanizálás célja, hogy korrozión elleni védelmet nyújtson és meghosszabbítsa a cső élettartamát. A zinccoating akkor működik, mint egy bárnya az acél és a környezet között, amely véd a csőt a rèsz és más korrozión kívüli hatásoktól.

Ez teszi a galvanizált összeragasztott csöveket alkalmasnak különböző alkalmazásokra, különösen azon iparágokban, ahol gyakran találkozunk nedvességgel vagy korrozív anyagokkal.

A galvanizált összefonódtatott csövek néhány fontos előnye közé tartozik:

1. Részvényszabályzat ellenállás: A zinkszint biztosítja a kiváló részvényszabályzat elleni védelmet, ami a galvanizált csöveket alkalmasára teszi az open-air és aluljárási alkalmazásokhoz.

2. Hosszú élettartam: A vas és zink kombinációja növeli a cső erőssége és hosszú élettartamát, lehetővé téve

a rohamos feltételek és intenzív használat ellenállását.

3. Költséghatékonyság: A galvanizált összefonódtatott csövek általánosan olcsóbbak más részvényszabályzat elleni alternatívákhoz képest, ami egy költséghatékony választást jelent számos projekt esetében.

4. Könnyű telepítés: A galvanizált összefonódtatott csövek viszonylag könnyen telepíthetőek standard méretek miatt és kompatibilitás miatt

gyakran használt illesztők és csatlakozókkal.

5. Bőséges alkalmazhatóság: A galvanizált összefonódtatott csövek különböző méretekben és vastagságokban érhetőek el, amelyek alkalmasak széles körű alkalmazásokra, beleértve a vízműszaki, építészi, mezőgazdasági és ipari projekteket.

Fontos megjegyezni, hogy a galvanizált összefonódtatott csoborok korlátokkal rendelkeznek. Az idő múltával a zinckövér elbomlik vagy leesik,

különösen agresszív korróziós környezetekben. Ezért szükséges szabadszínu ellenőrzés és karbantartás annak biztosítására, hogy a cső védelme folyamatosan fenntartsa.

Ezenkívül, amikor galvanizált összefonódtatott csoborokkal dolgozunk, fontos megfelelő biztonsági intézkedéseket tenni, például használni

megfelelő személyes védőeszközöket és biztosítani a megfelelő ventilációt, mivel a galvanizálási folyamat gázokat bocsáthat ki, amelyek sérüllyeggé tehetik az egészséget, ha belélegzik.

Alkalmazások:

építés, gépjárművek, kohásbányászat, kémiai ipar, villamoserőmű, vasúti járművek, autóipar, út, híd, tároló, sportlétesítmények, mezőgazdasági gépek, olajgépészeti gépek, kitermelő gépek és más gyártási iparágak.

Műszaki adatok:

| Galvanizált Kerek Acélcső | |||||||||

| Szabvány: API 5L, API 5CT, ASTM A53, ASTM A500, GB9711.1 Alkalmazás: Fölgázolási célokra való használat, víz és olaj továbbítására az olaj- és természetes gáziparban. és használat a szerkezeti acélcsövek céljaira. Fő Acélcsöv Osztály: GR.A, GR.B, GR.C, Q195, Q235B, Q345B és így tovább. |

|||||||||

| Inch | OD(mm) | Szabványos Falvastagság | |||||||

| SCH 10WT (mm) | SCH 20WT (mm) | SCH 40WT (mm) | SCH 60WT (mm) | SCH 80WT (mm) | SCH 100WT (mm) | SCH 160WT (mm) | XXS (mm) | ||

| 1/4” | 13.7 | 2.24 | 3.02 | ||||||

| 3/8” | 17.1 | 2.31 | 3.2 | ||||||

| 1/2” | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.5 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.7 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.7 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

| 30" | 762 | 7.92 | 12.7 | ||||||

| 32" | 813 | 7.92 | 12.7 | 17.48 | |||||

| 34" | 863 | 7.92 | 12.7 | 17.48 | |||||

| 36" | 914 | 7.92 | 12.7 | 19.05 | |||||

| 38" | 965 | ||||||||

| 40" | 1016 | ||||||||

| 42" | 1066 | ||||||||

| 44" | 1117 | ||||||||

| 46" | 1168 | ||||||||

| 48" | 1219 | ||||||||

Versenyelőny:

Versenyképes árakat és időben történő szállítást kínálunk a seemless acélcsövek ellátásában, nemcsak nagy mennyiségű vásárlók számára, hanem személyre szabott tervezési, specifikációs és csomagolási követelményeket is elfogadunk ügyfeleinktől mintavétel során.

Barátságos csapatunk szívesen hallaná Önt!