| Tempat Asal: | Shandong, China |

| Nama Merek: | jinzheng |

| Nomor Model: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grade1、Grade3、Grade4、Grade6、Grade7、Grade8、Grade9、Grade10、Grade11 |

| Sertifikasi: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| Kuantitas Pesanan Minimum: | 1 ton |

| Harga: | $650/ton |

| Detail Kemasan: | Standar Pengepakan Ekspor (Dalam ikatan kantong nilon, kotak kayu atau sesuai permintaan) |

| Waktu Pengiriman: | 15-20hari |

| Ketentuan Pembayaran: | FOB 30%T/T, 70% sebelum pengiriman |

| CIF 30% pembayaran awal dan sisa harus dibayar sebelum pengiriman dilakukan | |

| atau L/C 100% Irrevocable pada pandangan | |

| Kemampuan Penyediaan: | 2000 Ton/Tons per Bulan |

Detil cepat:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,pipa tanpa sambungan,Pipa Tanpa Sambungan Karbon dan Alloy untuk Tabung Mesin

Pipa baja A333 untuk suhu rendah digunakan secara luas di bidang petrokimia, gas alam, kimia, listrik, pemanasan, dan lainnya. Rentang aplikasi yang luas, fleksibel, Digunakan dalam pipa transmisi minyak dan gas alam, peralatan petrokimia, sistem saluran pendingin udara, cooler, pembangkit uap, serta digunakan dalam pemrosesan mekanik, wadah bertekanan, pembuatan boiler, struktur baja bangunan, tempat besar, pusat pameran, mesin angkat, pembuatan kapal, rak penyimpanan, dekorasi, fasilitas transportasi, pembangunan bandara, penyangga jembatan, garasi tiga dimensi, iklan luar ruangan, peralatan kebugaran, Pembuatan kendaraan dan industri lainnya

Kebutuhan Kimia

| Elemen | Komposisi,% | ||||||||

| Tingkat 1A | Tingkat 3 | Nilai 4 | Tingkat 6A | Tingkat 7 | Kelas 8 | Tingkat 9 | Tingkat 10 | Tingkat 11 | |

| Karbon,maks | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Mangan | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 maks | 0.90 maks | 0.40-1.06 | 1.15-1.50 | 0.60 Maks |

| Fosfor, maks | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Sulfur, maks | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Silikon | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 min | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 maks |

| Nikel | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 Maks | 35.0 -37.0 |

| Kromium | - | - | 0.44-1.01 | - | - | - | - | 0.15 maks | 0.50 maks |

| Tembaga | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 maks | - |

| Aluminium | - | - | 0.04-0.30 | - | - | - | - | 0.06maks | - |

| Vanadium, maks | - | - | - | - | - | - | - | 0.12 | - |

| Columbium, maks | - | - | - | - | - | - | - | 0.05 | - |

| Molybdenum, maks | - | - | - | - | - | - | - | 0.05 | 0.50 maks |

| Kobalt | - | - | - | - | - | - | - | - | 0.50 maks |

Persyaratan Tarik

| Kelas 1 | Tingkat 3 | Kelas 6 | Tingkat 7 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Kekuatan tarik, minKekuatan lentur, min | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Longitudinal | Traverse | Lemparan | Traverse | Lemparan | Traverse | Lemparan | Traverse | |

| Regangan dalam 2 in. atau 50mm, (atau 40). min, %:Regangan minimum dasar untuk dinding 5/16 in. (8 mm) dan lebih tebal dalam tebal, uji strip dan untuk semua kecil ukuran diuji pada bagian penuh ketika standar bulat 2-in. atau pengukur 50-mm panjang atau ukuran yang lebih kecil secara proporsional contoh uji dengan panjang pengukur sama dengan 4D (4 kali diameter) adalah digunakan Untuk uji strip, pengurangan untuk setiap penurunan 1/32 in. [0,8 mm] dalam tebal dinding di bawah 5/16 in. (8 mm) dari elongasi minimum dasar dari persentase berikut |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| Kelas 8 | Tingkat 9 | Tingkat 10 | Tingkat 11 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Kekuatan tarik, minKekuatan lentur, min | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Longitudinal | Traverse | Lemparan | Traverse | Lemparan | Traverse | Lemparan | ||

| Regangan dalam 2 in. atau 50mm, (atau 40). min, %:Dasar elongasi minimum untuk dinding 5/16 in. (8 mm) dan lebih tebal dalam ketebalan, uji strip. Dan untuk semua ukuran kecil yang diuji dalam bagian penuh. Ketika standar bulat 2-in. atau spesimen uji ukuran kecil sepanjang 50-mm dengan panjang jarak ukur sama dengan 4D (4 kali diameter) adalah digunakan. Untuk uji strip, pengurangan untuk setiap penurunan 1/32 in. [0,8 mm] dalam ketebalan dinding di bawah 5/16 in. (8 mm) dari elongasi minimum dasar berikut ini dalam persentase 22 16 1,25B persentase |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Deskripsi

1. Pendahuluan singkat produk

Pipa baja tanpa sambungan suhu rendah主要用于 minyak bumi, kimia, gas alam, dan batubara sebagai bahan baku etilen, propilen, urea, amonia sintetis, pupuk majemuk N-P-K, serta dalam industri farmasi untuk pencucian, pemurnian, desulfurisasi, dan penghilangan lemak produksi. Selain itu, digunakan dalam pembuatan peralatan pendinginan, penyimpanan suhu sangat rendah, transportasi gas cair suhu sangat rendah, dan komponen pipa. Sistem internasional pipa baja tanpa sambungan suhu rendah diwakili oleh ASTM A333/A333M-2011 (selanjutnya disebut standar AS), yang cocok untuk lingkungan suhu rendah hingga -196℃. Saat ini, produksi dan penerimaan pipa baja tanpa sambungan suhu rendah di seluruh dunia sebagian besar menggunakan standar AS, dan desain domestik juga merujuk pada standar AS. Dari sembilan tingkat pipa kriogenik standar AS, Gr.6 secara luas digunakan dalam industri petrokimia dan transportasi fluida di daerah suhu rendah dan dingin, dengan permintaan tahunan di pasar AS dan Eropa lebih dari 20.000 ton.

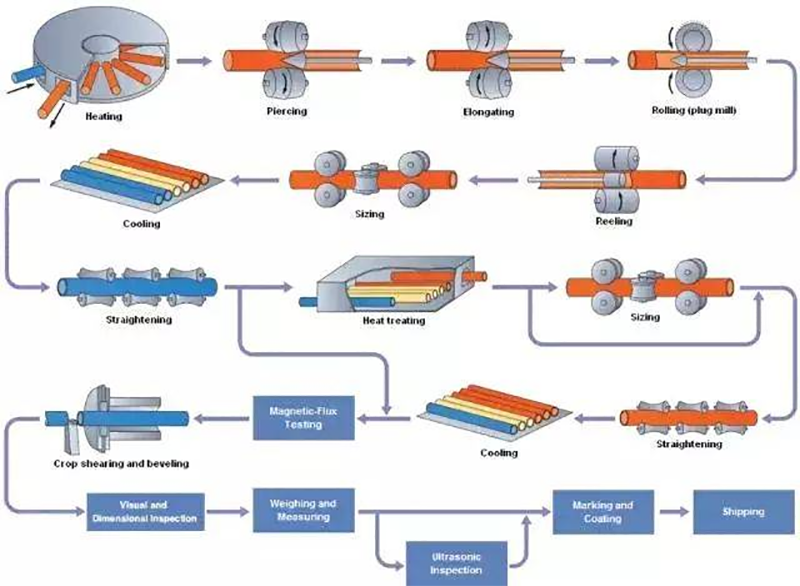

2. Proses Pembuatan

Pembuatan - Tabung dibuat dengan proses penyambungan yang tanpa sambungan atau tidak menambahkan logam pengisi. Tingkat 4 harus dibuat dengan proses tanpa sambungan.

Pengolahan panas

Semua pipa tanpa sambungan dan ber-sambungan harus diolah panas untuk mengontrol mikrostruktur mereka dengan salah satu metode berikut.

Dipanaskan secara merata hingga tidak kurang dari 1500F (815℃) untuk pengolahan panas positif, lalu didinginkan dengan udara atau didinginkan di ruang pendinginan dari tungku oksigen udara terkendali.

Pipa baja dinormalisasi dan dipanaskan kembali ke suhu pemanjangan yang sesuai seperti yang ditentukan oleh pabrik baja. Pemanasan ulang pipa dengan baik mengontrol pemrosesan panas, sehingga suhu operasi pembentukan panas dikendalikan dalam rentang suhu pembentukan panas 1550 hingga 1750F (845-945 ° C), lalu didinginkan di tungku gas oksigen terkendali dengan suhu awal tidak kurang dari 1550 (845 ° C). Metode ini hanya cocok untuk proses tabung tanpa jahitan.

Bahan tersebut diolah dan dipanaskan kembali hingga suhu pengerasan yang sesuai sebagaimana ditentukan oleh pabrik.

Ketika dinyatakan dalam pesanan, sampel harus dipotong dari blok uji ketebalan, yang diambil dari pipa baja yang telah diolah panasnya, dan harus dilepaskan dari tegangan. Blok uji harus dipanaskan secara bertahap hingga suhu yang ditentukan, diberi kelembapan pada suhu ini selama waktu yang ditentukan, lalu didinginkan hingga suhu tidak lebih tinggi dari 600F (315°C). Blok uji untuk pipa baja tipe 8 harus didinginkan dengan udara atau air pada laju pendinginan minimum 300F/ (165℃/h) hingga suhu tidak lebih tinggi dari 600F (315℃).

3. Merek utama atau tipe baja produk

ASTM A333-Grade1、Grade4、Grade6、Grade7、Grade9、Grade10

ASTM A334-Grade1、Grade6、Grade7、Grade9

API 5CT80、L80-1、L803Cr、P110

4. Standar pelaksanaan produk

GSTM 8333、 GSTM 8334、 API SPEC 5CT (edisi ke-9)

5. Ciri-ciri produk

Perusahaan tahan terhadap suhu rendah dan tidak berpembuluh, penggunaan baja murni tinggi dengan sulfur rendah dan fosfor rendah serta perlakuan kalsifikasi dapat secara efektif mengurangi kekeroposan baja pada suhu rendah, meningkatkan ketangguhan dampak produk. Perusahaan memiliki tangki pendingin 0 "-100C, yang dapat melakukan uji ketangguhan suhu rendah secara bertahap untuk menjamin kualitas dan stabilitas produk.

6. Lingkungan penggunaan produk

Tabung kriogenik A333 dan A334 digunakan untuk pipa tangki kriogenik kelas -45 hingga -195C, serta pipa penukar panas kriogenik. Mereka juga dapat digunakan sebagai pipa pengangkutan fluida di lingkungan suhu rendah. Casing tahan suhu rendah API5CT terutama digunakan untuk pengeboran sumur di daerah yang sangat dingin. Pipa baja dapat digunakan pada suhu sangat rendah, tetapi juga memiliki kekuatan tinggi, ketahanan korosi, kemampuan proses yang baik, dan sifat las yang baik. Karakteristik ini membuat pipa baja suhu rendah A333GR.6 banyak digunakan di bidang industri minyak, gas alam, kimia, dan lainnya.

7. Rentang spesifikasi produk

Diameter luar: 16mm~323.9mm; Ketebalan dinding: 2.0mm~40.0mm

Aplikasi:

Luas digunakan di bidang petrokimia, gas alam, kimia, listrik, pemanasan, dan lainnya. Rentang aplikasi yang luas, fleksibel, Dalam pipa transmisi minyak dan gas alam, peralatan petrokimia, sistem pipa pendingin udara, cooler, pembangkit uap, tetapi juga digunakan dalam pengolahan mesin, wadah bertekanan, pembuatan boiler, struktur baja bangunan, tempat besar, pusat pameran, mesin angkat, pembuatan kapal, rak penyimpanan, dekorasi, fasilitas transportasi, pembangunan bandara, penyangga jembatan, penyangga tambang, garasi tiga dimensi, iklan outdoor, peralatan kebugaran, Pembuatan kendaraan dan industri lainnya

Spesifikasi:

Standar pipa baja tanpa sambungan

| API SPEC 5L | |||

| Nama Produk | Standar Eksekutif | Dimensi (mm) | Kode Baja / Kelas Baja |

| Pipa Garis | Api 5l | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1/PSL2 |

| API SPEC 5CT | |||

| Nama Produk | Standar Eksekutif | Dimensi (mm) | Kode Baja / Kelas Baja |

| Casing | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Selubung | API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Nama Produk | Standar Eksekutif | Dimensi (mm) | Kode Baja / Kelas Baja |

| Pipa Baja Tanpa Sambungan Berlapis Zink Hot-Dipped dan Hitam | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Pipa Baja Karbon Tanpa Sambungan untuk Pelayanan Temperatur Tinggi | Astm a106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Tabung Pendingin dan Pengganti Uap Baja Karbon Rendah Tanpa Sambungan yang Ditarik Dingin | ASTM A179 | ø10.3~426x WT1.0~36 | Baja karbon rendah |

| Tabung Boiler Baja Karbon Tanpa Sambungan untuk Tekanan Tinggi | ASTM A192 | ø10.3~426 x WT1.0~36 | Baja karbon rendah |

| Tabung Penukar Panas dan Kondensor Baja Paduan Tarik Dingin Tanpa Sambungan | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Tabung Ketel dan Superpanas Baja Karbon Sedang Tanpa Sambungan | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Tabung Ketel, Superpanas, dan Penukar Panas Baja Paduan Ferritik & Austenitik Tanpa Sambungan | Astm a213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Baja Karbon dan Baja Paduan Tanpa Sambungan untuk Tabung Mekanis | ASTM A333 | ø1/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Pipa Baja Karbon & Pipa Baja Paduan Tanpa Sambungan dan Disambungkan untuk Penggunaan Suhu Rendah | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Tabung Pemanas Air Umpan Baja Karbon Tarik Dingin Tanpa Sambungan | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Nama Produk | Standar Eksekutif | Dimensi (mm) | Kode Baja / Kelas Baja |

| Tabung Baja Tanpa Sambungan untuk Suhu Tinggi | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Tabung Baja Tanpa Sambungan | DIN 1629 \/ DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Tabung Baja Tanpa Sambungan | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Pipa Baja Tanpa Sambungan untuk Kegunaan Struktural | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| Nama Produk | Standar Eksekutif | Dimensi (mm) | Kode Baja / Kelas Baja |

| Tabung Baja Tanpa Sambungan untuk Struktur Mesin | BS 970 | ø10~762x WT1.0~120 | Baja Karbon |

| Tabung Baja Tanpa Sambungan untuk Boiler dan Penukar Panas | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Keunggulan Kompetitif:

1. Berat ringan.

Parameter ini adalah 1/5 dari baja persegi, sehingga memiliki performa bobot dan ringan yang lebih baik, lebih ringan daripada baja persegi, dan bobotnya hanya 1/5 dari baja persegi.

2. Tahan korosi dan tahan suhu tinggi.

Memiliki sifat tahan korosi dan tahan suhu tinggi yang baik, lebih unggul dibandingkan baja persegi, A333 tahan terhadap asam, basa, garam, dan korosi lingkungan atmosfer, tahan suhu tinggi, daya tahan benturan dan kelelahan yang baik, tidak memerlukan pemeliharaan rutin, dan umur layanan efektif dapat mencapai lebih dari 15 tahun.

3, tidak mengalami deformasi dan anti-statik.

Memiliki sifat anti-statik yang baik, lebih unggul dibandingkan pipa baja biasa, pipa tanpa sambungan sangat elastis, dapat digunakan kembali dalam peralatan mesin, tanpa memori, tidak mengalami deformasi, dan anti-statik, pipa tanpa sambungan memiliki sifat mekanis yang unggul, mudah untuk dimachining, dll.

Tim kami yang ramah sangat ingin mendengar dari Anda!