| Luogo di Origine: | Shandong, Cina |

| Nome del Marchio: | jinzheng |

| Numero di Modello: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grado1、Grado3、Grado4、Grado6、Grado7、Grado8、Grado9、Grado10、Grado11 |

| Certificazione: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| Quantità Minima di Ordine: | 1 tonnellata |

| Prezzo: | $650/t |

| Dettagli Imballo: | Standard di imballaggio per esportazione (In fasci con sacchi in nylon, cassette in legno o come richiesto) |

| Tempo di Consegna: | 15-20 giorni |

| Condizioni di pagamento: | FOB 30% T/T, 70% prima della spedizione |

| CIF 30% acconto e il saldo da pagare prima di effettuare la spedizione | |

| o Lettera di credito irrevocabile al 100% a vista | |

| Capacità di fornitura: | 2000 Ton/Tons al mese |

Rapido dettaglio:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,tubo senza saldatura,Tubi senza saldatura in acciaio carbonico e legato per uso meccanico

La tubazione in acciaio A333 per temperature basse è ampiamente utilizzata nei settori petrolchimico, gas naturale, chimico, elettricità, riscaldamento e altri campi. La sua vasta gamma di applicazioni è flessibile, utilizzata in condotte di trasporto di petrolio e gas naturale, attrezzature petrolchimiche, sistemi di condizionamento, tubazioni di cooler, generatori a vapore, ma anche nel trattamento meccanico, contenitori sotto pressione, costruzione di caldaie, strutture d'acciaio edili, grandi luoghi, centri espositivi, macchinari di sollevamento, costruzione navale, scaffali di stoccaggio, decorazione, impianti di trasporto, costruzione di aeroporti, supporto di ponti, supporto minerario, parcheggi a tre dimensioni, pubblicità all'aperto, attrezzatura fitness, produzione veicolare e altre industrie.

Requisiti chimici

| Elemento | Composizione,% | ||||||||

| Grado 1A | Grado 3 | Classe 4 | Grado 6A | Grado 7 | Grado 8 | Grado 9 | Grado 10 | Grado 11 | |

| Carbonio, max | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Altri prodotti | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 max | 0.90 max | 0.40-1.06 | 1.15-1.50 | 0.60 Max |

| Fosforo, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Zolfo, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Di silicio | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 min | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 max |

| Nichel | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0,25 Max | 35.0 -37.0 |

| Cromo | - | - | 0.44-1.01 | - | - | - | - | 0.15 max | 0.50 max |

| Rame | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 max | - |

| Alluminio | - | - | 0.04-0.30 | - | - | - | - | 0.06max | - |

| Vanadio, max | - | - | - | - | - | - | - | 0.12 | - |

| Niobio, max | - | - | - | - | - | - | - | 0.05 | - |

| Molibdeno, max | - | - | - | - | - | - | - | 0.05 | 0.50 max |

| Di ferro | - | - | - | - | - | - | - | - | 0.50 max |

Requisiti di resistenza

| Grado 1 | Grado 3 | Grado 6 | Grado 7 | |||||

| psi | Mpa | psi | Mpa | psi | Mpa | psi | Mpa | |

| Resistenza a trazione, minResistenza a yield, min | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Longitudinale | Trasversale | Lungo | Trasversale | Lungo | Trasversale | Lungo | Trasversale | |

| Allungamento in 2 pollici o 50mm, (o 40). min, %: Allungamento minimo di base per pareti spesse 5/16 pollici (8 mm) e oltre in spessore, test su strisce e per tutti i piccoli dimensioni testate in sezione completa quando standard rotondo da 2 pollici o 50 mm di misura lunghezza o proporzionalmente dimensione minore campione di prova con la lunghezza di misura uguale a 4D (4 volte il diametro) è usato. Per i test a striscia, una deduzione per ogni diminuzione di 1/32 pollice [0,8 mm] in spessore del muro al di sotto dei 5/16 pollici (8 mm) dal minimo base di allungamento del seguente percentuale |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| Grado 8 | Grado 9 | Grado 10 | Grado 11 | |||||

| psi | Mpa | psi | Mpa | psi | Mpa | psi | Mpa | |

| Resistenza a trazione, minResistenza a yield, min | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Longitudinale | Trasversale | Lungo | Trasversale | Lungo | Trasversale | Lungo | ||

| Allungamento in 2 pollici o 50mm, (o 40). min, %:Base allungamento minimo per pareti spesse 5/16 in. (8 mm) e superiori in spessore, test su strisce. E per tutte le piccole dimensioni testate in sezione completa. Quando lo standard rotondo da 2 in. o 50 mm con lunghezza di prova o dimensione proporzionalmente più piccola con la lunghezza di prova uguale a 4D (4 volte il diametro) è utilizzato. Per i test su strisce, una deduzione per ogni diminuzione di 1/32 in. [0,8 mm] dello spessore della parete inferiore a 5/16 in. (8 mm) dall'allungamento minimo base del seguente percentuale |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Descrizione

1. Breve introduzione del prodotto

Il tubo d'acciaio senza saldatura a bassa temperatura è principalmente utilizzato nel petrolio, chimico, gas naturale e carbone come materie prime per etilene, propilene, urea, ammoniaca sintetica, fertilizzanti composti N-P-K e industria farmaceutica per la lavaggio, purificazione, desolfurizzazione e degrassaggio della produzione, nonché per la fabbricazione di attrezzature a bassa temperatura, magazzino ad ultra-bassa temperatura, trasporto di gas liquefatto ad ultra-bassa temperatura e componenti tubolari. Il sistema internazionale di tubi d'acciaio senza saldatura a bassa temperatura è rappresentato da ASTM A333/A333M-2011 (di seguito indicato come standard americano), il quale è adatto a un ambiente a bassa temperatura fino a -196℃. Attualmente, la produzione e l'accettazione dei tubi d'acciaio senza saldatura a bassa temperatura nel mondo utilizzano prevalentemente lo standard americano, e anche i progetti nazionali si riferiscono allo standard americano. Tra i nove gradi del tubo criogenico dello standard americano, Gr.6 è ampiamente utilizzato nell'industria petrolchimica e nel trasporto di fluidi in aree a bassa temperatura e fredde, e la richiesta annuale nei mercati americani ed europei supera le 20.000 t.

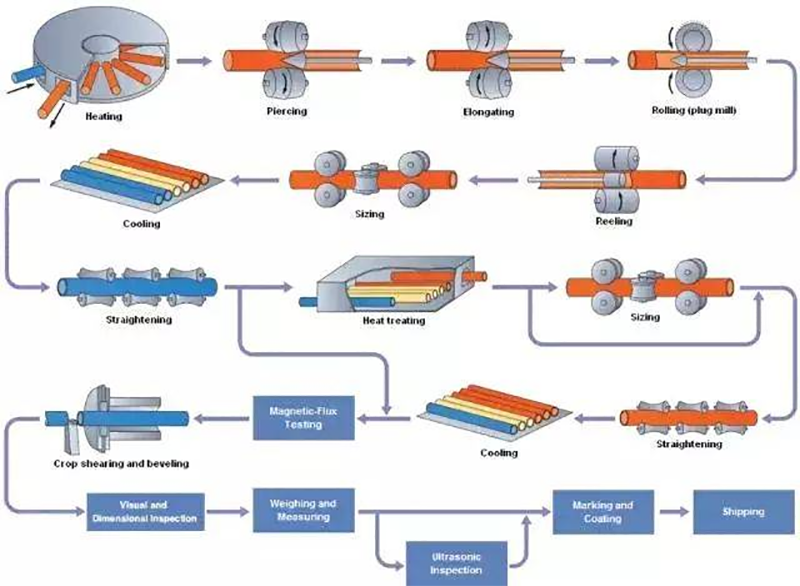

2. Processo di produzione

Produzione - I tubi vengono realizzati tramite processi di saldatura che sono senza giunture o non aggiungono metallo riempitivo. Il livello 4 dovrà essere realizzato con un processo senza giunzioni.

Trattamento termico

Tutti i tubi senza giunzioni e saldati dovranno essere trattati termicamente per controllare la loro microstruttura mediante uno dei seguenti metodi.

Riscaldati uniformemente a non meno di 1500F (815℃) per una trattamento termico positivo, e poi raffreddati a temperatura ambiente o raffreddati nella camera di raffreddamento del forno a controllo dell'aria ossigenata.

La cannella in acciaio viene normalizzata e riscaldata a una temperatura appropriata di tempertura determinata dalla fonderia di acciaio. Il riscaldamento della cannella controlla bene il processo di lavorazione a caldo, in modo che la temperatura operativa della formazione a caldo sia controllata all'interno dell'intervallo di temperatura di formazione a caldo di 1550 a 1750F (845-945 ° C), e poi viene raffreddata nel forno a controllo di gas ossigenato con una temperatura iniziale di non meno di 1550 (845 ° C). Questo metodo è adatto solo ai processi di tubi senza cuciture.

Viene trattato e riscaldato nuovamente alla temperatura appropriata di tempra, come determinato dalla fabbrica.

Quando specificato nell'ordine, il campione deve essere tagliato dal blocco di prova corrispondente allo spessore, prelevato dalla tubazione in acciaio sottoposta a trattamento termico, ed esso deve essere sottoposto a alleviamento delle tensioni. Il blocco di prova deve essere riscaldato progressivamente fino alla temperatura specificata, mantenuto umido a questa temperatura per il tempo specificato e poi raffreddato a una temperatura non superiore ai 600F (315 °C). Il blocco di prova della tubazione in acciaio di grado 8 deve essere raffreddato ad aria o ad acqua con un minimo tasso di raffreddamento di 300F/ (165℃/h) fino a una temperatura non superiore ai 600F (315℃).

3. La marca principale o il tipo di acciaio del prodotto

ASTM A333-Grade1, Grade4, Grade6, Grade7, Grade9, Grade10

ASTM A334-Grade1, Grade6, Grade7, Grade9

API 5CT80, L80-1, L803Cr, P110

4. Standard di implementazione del prodotto

GSTM 8333, GSTM 8334, API SPEC 5CT (9th)

5. Caratteristiche del prodotto

L'azienda è resistente a temperature basse e non vascolari, utilizza acciaio di alta purezza con basso contenuto di zolfo e fosforo e trattamento di calcificazione, che può ridurre efficacemente la fragilità a bassa temperatura dell'acciaio, migliorando la tenuta al impatto dei prodotti. L'azienda dispone di una vasca di raffreddamento da 0 °C a -100°C, che consente di eseguire test di impatto a bassa temperatura in serie per garantire la qualità e la stabilità dei prodotti.

6. Ambiente di utilizzo del prodotto

I tubi criogenici A333 e A334 vengono utilizzati per i tubi del serbatoio criogenico di grado -45-195C e per i tubi degli scambiatori di calore criogenici. Possono inoltre essere utilizzati come tubi di trasporto fluido in ambienti a bassa temperatura. Il rivestimento API5CT resistenti al freddo è principalmente usato per il trivellamento di pozzi in aree estremamente fredde. La cannella in acciaio può essere utilizzata a temperature estremamente basse, ma ha anche alta resistenza, resistenza alla corrosione, buone capacità di lavorazione e saldabilità. Queste caratteristiche fanno sì che la cannella in acciaio A333GR.6 per temperature basse venga ampiamente utilizzata nei settori petrolifero, del gas naturale, chimico e in altri campi industriali.

7. Ampia gamma di specifiche dei prodotti

Diametro esterno: 16mm~323.9mm; Spessore del muro: 2.0mm~40.0mm

Applicazioni:

Ampiamente utilizzato nei settori petrochimico, gas naturale, chimico, elettricità, riscaldamento e altri campi. Ampia gamma di applicazioni, flessibile, utilizzato in pipeline per il trasporto di petrolio e gas naturale, attrezzature petrochimiche, sistemi di condizionamento d'aria, tubazioni per impianti di raffreddamento, generatori a vapore, ma anche nel trattamento meccanico, vasche sotto pressione, costruzione di caldaie, strutture in acciaio edili, grandi luoghi, centri espositivi, macchinari di sollevamento, costruzione navale, scaffali di magazzino, arredamento, infrastrutture di trasporto, costruzione di aeroporti, supporto per ponti, supporto per miniere, parcheggi a tre dimensioni, pubblicità all'aperto, attrezzature fitness, produzione di veicoli e altre industrie.

Specifiche:

Norme per tubi d'acciaio senza saldatura

| API SPEC 5L | |||

| Nome del prodotto | Norma esecutiva | Dimensione (mm) | Codice Acciaio / Classe Acciaio |

| Tubi per linee di trasporto | API 5L | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| Nome del prodotto | Norma esecutiva | Dimensione (mm) | Codice Acciaio / Classe Acciaio |

| Custodia | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubing | API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Nome del prodotto | Norma esecutiva | Dimensione (mm) | Codice Acciaio / Classe Acciaio |

| Tubi in acciaio senza saldatura neri e rivestiti a caldo con zinco | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Tubi in acciaio al carbonio senza saldatura per servizio ad alta temperatura | Astm a106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Tubi per scambiatori di calore e condensatori in acciaio basso-carbonio estrusi a freddo senza saldatura | ASTM A179 | ø10.3~426x WT1.0~36 | Acciaio al carbonio basso |

| Tubi per caldaie in acciaio al carbonio senza saldatura per alte pressioni | ASTM A192 | ø10.3~426 x WT1.0~36 | Acciaio al carbonio basso |

| Tubi per scambiatori di calore e condensatori in acciaio legato intermedio senza saldatura, estrusi a freddo | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Tubi per caldaie e sovra-riscaldatori in acciaio al carbonio medio senza saldatura | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Tubi per caldaie, sovra-riscaldatori e scambiatori di calore in acciaio ferritico e austenitico legato senza saldatura | Astm a213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Acciaio al carbonio senza giunture e acciaio legato per tubazioni meccaniche | ASTM A333 | ø1/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Tubi in acciaio al carbonio senza giunture e saldati e tubi in acciaio legato per l'uso a bassa temperatura | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Tubi per scambiatori di calore in acciaio al carbonio freddo trafilato senza giunture | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Nome del prodotto | Norma esecutiva | Dimensione (mm) | Codice Acciaio / Classe Acciaio |

| Tubi in acciaio senza saldatura per temperature elevate | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Tubi in acciaio senza saldatura | DIN 1629 \/ DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Tubi in acciaio senza saldatura | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Tubi in Acciaio Senza Saldatura per Scopi Strutturali | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| Nome del prodotto | Norma esecutiva | Dimensione (mm) | Codice Acciaio / Classe Acciaio |

| Tubi in Acciaio Senza Saldatura per Strutture Macchine | BS 970 | ø10~762x WT1.0~120 | Acciaio al carbonio |

| Tubi in Acciaio Senza Saldatura per Caldaie e Cambiatori di Calore | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Vantaggio Competitivo:

1. Leggero.

Il parametro è 1/5 del quadrato d'acciaio, quindi ha un miglior rapporto peso/prestazioni, è più leggero del quadrato d'acciaio e il suo peso è solo 1/5 di quello del quadrato d'acciaio.

2. Resistenza alla corrosione e a temperature elevate.

Ha buona resistenza alla corrosione e alle alte temperature, migliore rispetto al quadrato d'acciaio, A333 resiste alla corrosione da acido, alcali, sale e ambiente atmosferico, resistente alle alte temperature, con buona resistenza agli impatti e alla fatica, non necessita di manutenzione regolare, la durata effettiva può raggiungere più di 15 anni.

3, nessuna deformazione e antistatico.

Ha buone proprietà antistatiche, migliori rispetto alle normali tubazioni in acciaio, i tubi senza saldatura sono altamente elastici, riutilizzabili in attrezzature meccaniche, senza memoria, senza deformazione e antistatici, i tubi senza saldatura hanno eccellenti proprietà meccaniche, facile lavorazione, ecc.

Il nostro team amichevole adora sentire le tue notizie!