| Luogo di Origine: | Shandong, Cina |

| Nome del Marchio: | Changshengda(CSD) |

| Numero di Modello: | Q195/Q235/Q345 SS400 |

| Certificazione: | API, CE, GS, ISO9001 |

| Quantità Minima di Ordine: | 20 tonnellate |

| Prezzo: | 545USD/TON-680USD/TON |

| Dettagli Imballo: | 1.Imballo marittimo standard |

| 2.Secondo le richieste del cliente | |

| Porto: | Porti di Shanghai, Tianjin, Qingdao, puoi specificare altri porti in base alle tue esigenze. |

| Tempo di Consegna: | 8-14giorni |

| Condizioni di pagamento: | Lettera di credito, lettera di credito/debito |

| Capacità di fornitura: | 100000tonnellate/mese |

| Materiale: | ERW:Q235, Q345, 20#, J55, X42~65, ecc. |

| LASW:Q195,Q235,Q345B,X42,X52,X60,S355JRH,S355J0H,S355J2H ecc |

Descrizione:

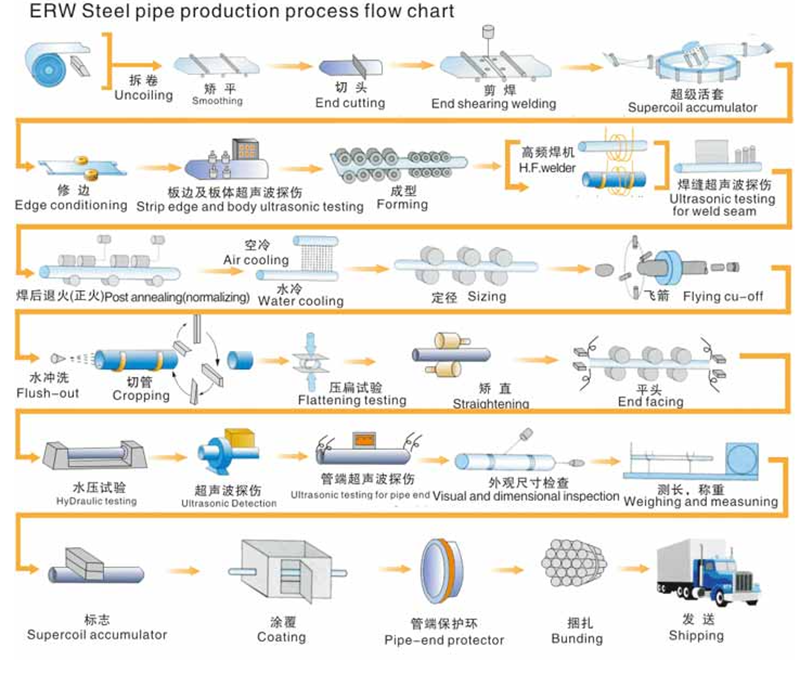

Il saldatura a filo retto ad alta frequenza (ERW) è divisa in due forme: saldatura per induzione e saldatura per contatto, a seconda del metodo di saldatura. Utilizza bobine larghe caldo-laminate come materiale grezzo e subisce pre-flessione, formazione continua, saldatura, trattamento termico, dimensionamento, raddrizzamento, taglio, ecc. Rispetto al processo elicoidale, ha i vantaggi di giunti più corti, alta precisione dimensionale, spessore uniforme, buona qualità superficiale e alta resistenza alla pressione. Tuttavia, lo svantaggio è che può produrre solo tubi sottili di piccolo e medio diametro, e sono propensi a verificarsi macchie grigie e mancanza di fusione nei punti di saldatura, nonché difetti di corrosione a solco. Attualmente, i settori di utilizzo più diffusi sono il gas urbano, il trasporto di petrolio grezzo e di prodotti petroliferi raffinati, ecc.

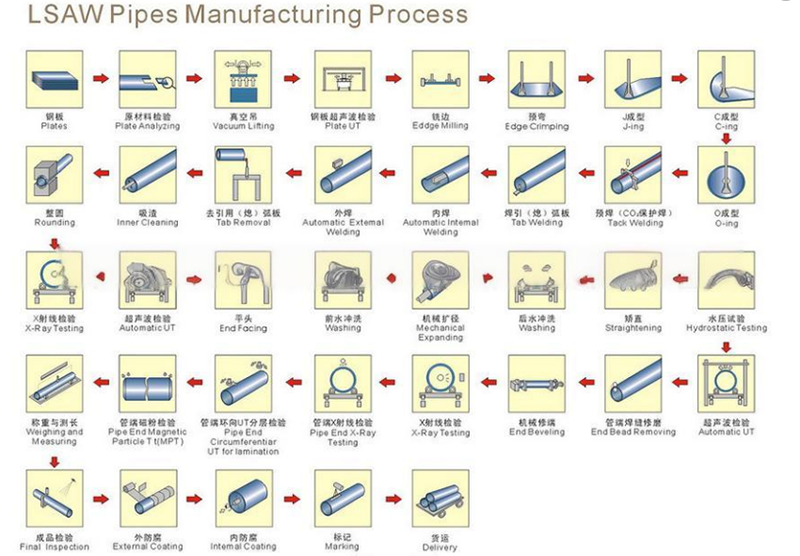

Il filo retto a fusione sottacquea (LSAW) viene prodotto utilizzando una singola lamiera media-spessa come materiale grezzo, premettendo (ruotando) la lamiera in un modello o macchina di formatura e utilizzando il saldatura a fusione sottacquea su entrambi i lati e l'espansione del diametro. L'intervallo delle specifiche dei prodotti finiti è ampio, la tenuta, la plasticità, l'uniformità e la densità del saldatore sono buone, e presenta i vantaggi di un diametro di tubo grande, parete spessa, alta resistenza alla pressione, resistenza al freddo e forte resistenza alla corrosione. Nella costruzione di condotte petrolifere e gaziste a lunga distanza ad alta resistenza, alta tenuta e alta qualità, gran parte dei tubi richiesti sono tubi retti a fusione sottacquea con diametro grande e parete spessa. Secondo gli standard API, nelle grandi condotte di trasporto di petrolio e gas, il tubo a saldatura retta sottacquea è l'unico tipo di tubo designato applicabile quando si attraversano aree di Classe 1 e Classe 2 come zone montagnose, fondali marini e aree urbane densamente popolate.

In base ai diversi metodi di modellazione, può essere diviso in:

Tubo acciaio UOE: Dopo che la singola lamiera viene pre-ricurva al bordo, subisce processi come formatura a U, formatura a O, saldatura interna, saldatura esterna e espansione meccanica a freddo.

Tubo acciaio JCOE: cioè, pre-saldatura, formatura e espansione a freddo dopo la saldatura secondo "J-C-O-E"

Tubo acciaio HME: formato dal metodo di laminazione con mandrino secondo "C-C-O", saldato e poi espanso a freddo.

Specifiche:

| Erw pipe | |

| ASTM | ASTM A53 B, ASTM A178, ASTM A252 GR.2, A500, ASTM A513 |

| EN | EN 10204/10217 S235JR,S275JR,S355,S355JR,S355J2H |

| API | API 5L X42/46/52/56/60/70 |

| Acciaio al carbonio | ASTM A671,ASTM A672 |

| Acciaio legato | ASTM A691 |

| - O | 1/2" - 24" (21.3mm-610mm) |

| Wt | 1.65mm-20mm |

| APPLICAZIONE | Tubo per Linee; OCTG (Prodotti Tubolari per l'Industria del Petrolio); Tubo Strutturale Rotondo; Tubo Imbottito. |

| Tubo di sega | |||

| Standard | ASTM 53 ;API Spec 5L;ASTM A252-89; EN10217, EN10219 | ||

| Gradi di acciaio | API 5L: GR A, GR B, X42, X46, X56, X60, X65, X70 ASTM A252 GR 1, GR 2, GR 3 ASTM A53: GR A, GR B, GR C, GR D BS 4360: Grado 43, Grado 50 EN: S275, S275JR, S355JRH, S355J2H |

||

| APPLICAZIONE | Utilizzato per petrolio/gas/acqua; Trasmissione; Ingegneria; Progetti offshore. | ||

| Utilizzo | Diametro esterno (mm) | WT(mm) | Lunghezza (m) |

| Tubo a ruota | 1200-3800(47.24”-150”) | 12-120 (1/2”- 4.7”) | <=3.2 |

| per costruzione (pali tubolari) | 350-1600(14”- 63”) | 6-60 (1⁄4” -2.36”) | 6-12 |

| Olio e gas pipeline | 406-1524(16”- 60”) | 6-40 (1⁄4”-1.57”) | 8-12.1 |

| In aggiunta alla specifica sopra indicata, le tubazioni possono essere prodotte in base alle richieste del cliente. | |||

Rapido dettaglio:

Descrizione:

Tubo d'acciaio con saldatura a singolo filo per il trasporto di fluidi a bassa pressione

Diametro: 219mm~508mm

Spessore delle pareti: 6mm~20mm

Norma: GB/T 3091-2008

Materiale: L245~L690, Q235, ecc.

Applicazioni: Adatto per tubi in acciaio saldati a cucitura retta utilizzati nel trasporto di fluidi a bassa pressione come acqua, gas, aria e vapore di riscaldamento e altre strutture.

Tubo in acciaio saldato a cucitura retta standard americano

Diametro: 219mm~406mm

Spessore del muro: 6mm~14mm

Norma: ASTM

Materiale: GrA GrB

Applicazioni: Utilizzato principalmente in progetti idraulici, industria petrolifera e del gas, industria chimica, industria elettrica, irrigazione agricola, costruzione urbana, ecc.

Tubi in acciaio a cucitura retta per rivestimenti petroliferi e tubi per petrolio

Diametro 219mm~508mm

Spessore del muro 6mm~20mm

Norma API-5CT

Materiale H40, J55, N80, P110

Applicazione: tubi per rivestimento e trasporto petrolifero.

Tubo d'acciaio saldato a spirale standard americano

Diametro 219mm~3520mm

Spessore del muro 5mm~26mm

Norma ASTM

Materiale Gr.A, Gr.B, Gr.C, Gr.1~Gr.11

Applicazione: Utilizzato principalmente in tubi a pali per progetti idraulici, industria petrolifera e del gas, industria chimica, industria elettrica, irrigazione agricola, costruzione urbana, ecc.

Tubi acciaio con giunzione a cerniera per il trasporto di petrolio e gas

Diametro 219mm~508mm

Spessore del muro 6mm~20mm

Norma API-5L

Materiale Gr.B, X42~X100

Applicazione: Utilizzato per il trasporto di petrolio e gas naturale.

Vantaggio Competitivo:

L'azienda ha selezionato tecnologie e attrezzature avanzate a livello internazionale: ad esempio la modellazione W-FF, il saldatura a induzione ad alta frequenza nello stato solido, il controllo degli difetti con ultrasuoni, la rilevazione di perdite tramite flusso magnetico e strumenti di prova di alto livello: come l'analisi metallografica, la duretometro Vickers, la macchina per test di impatto, spettrometri analizzatori, bancali di prova universali e altre attrezzature. Dal suo insediamento, ha ottenuto varie certificazioni e qualifiche onorifiche internazionali: come API 5L, API5CT, certificato di produzione di tubazioni sotto pressione ISO9002-2000, licenza di produzione di prodotti industriali, Certificato di Membri del Petróleo e Petrochimico Cinese, Certificato di Prodotto di Qualità Cinese, ecc. I prodotti vengono esportati in America del Sud, Nord America, Unione Europea, Sud-est asiatico e altri luoghi. Hanno ricevuto un'accoglienza favorevole da parte dei clienti in tutto il mondo per molti anni.

Il nostro team amichevole adora sentire le tue notizie!