| Luogo di Origine: | Shandong, Cina |

| Nome del Marchio: | $560-600/TON |

| Numero di Modello: | A106/A53GRB API5L/Q195,Q235,Q275,Q355,Q345/SAE1010/1020,1045, ecc. |

| Certificazione: | API, CE, Bsi, RoHS, SNI, BIS, tisi, KS, JIS, GS, ISO9001 |

| Quantità Minima di Ordine: | 1ton |

| Prezzo: | $560/TON |

| Dettagli Imballo: | Standard di imballaggio per esportazione (In fasci, sacchi di nylon, cassette di legno o come richiesto) |

| Tempo di Consegna: | 3-7 giorni |

| Condizioni di pagamento: | FOB 30% T/T, 70% prima della spedizione |

| CIF 30% acconto e il saldo da pagare prima di effettuare la spedizione | |

| o Lettera di credito irrevocabile al 100% a vista | |

| Capacità di fornitura: | 10000 Tonnelate al mese |

Descrizione:

La tubazione in acciaio galvanizzato si divide in tubi in acciaio galvanizzato a caldo e tubi in acciaio galvanizzato a freddo

Tubi galvanizzati a caldo

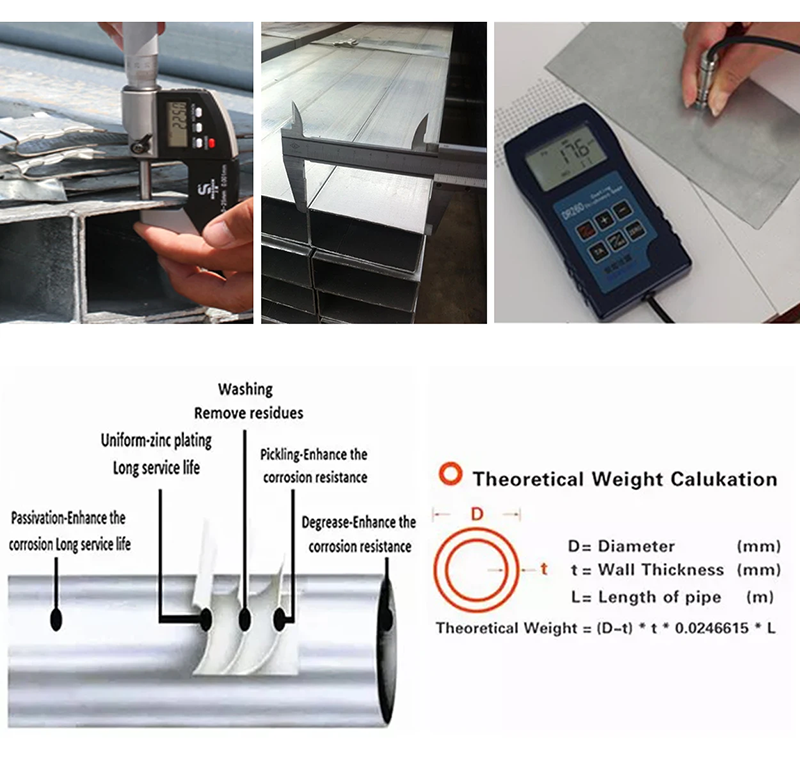

Il metallo fuso reagisce con una matrice di ferro per produrre un strato di lega, combinando così il substrato e lo strato di rivestimento. La galvanizzazione a immersione calda prevede innanzitutto l'acidificazione della tubatura in acciaio, per rimuovere l'ossido di ferro dalla superficie del tubo in acciaio; dopo l'acidificazione, viene lavata con una soluzione acquosa di cloruro di ammonio o cloruro di zinco o una soluzione acquosa mista di cloruro di ammonio e cloruro di zinco, quindi immersa nella vasca di galvanizzazione a caldo. La galvanizzazione a immersione calda offre i vantaggi di uno strato uniforme, adesione forte e lunga durata. La maggior parte dei processi settentrionali utilizza fasce galvanizzate per avvolgere direttamente lo zinco

Tubo galvanizzato a freddo

La galvanizzazione a freddo è elettrogalvanizzazione. La quantità di galvanizzazione è molto piccola, solo 10-50g/m2, e la sua resistenza alla corrosione è molto peggiore rispetto ai tubi galvanizzati a caldo. I produttori regolari di tubi galvanizzati, per garantire la qualità, in genere non utilizzano l'elettrogalvanizzazione (galvanizzazione a freddo). Solo piccole aziende con attrezzature limitate e vecchie usano acciaio elettrogalvanizzato, ovviamente i loro prezzi sono relativamente più bassi. Nelle case appena costruite, l'uso di tubi di acciaio galvanizzato a freddo come condutture d'acqua è vietato.

Differenza tra galvanizzazione a immersione calda e galvanizzazione a freddo

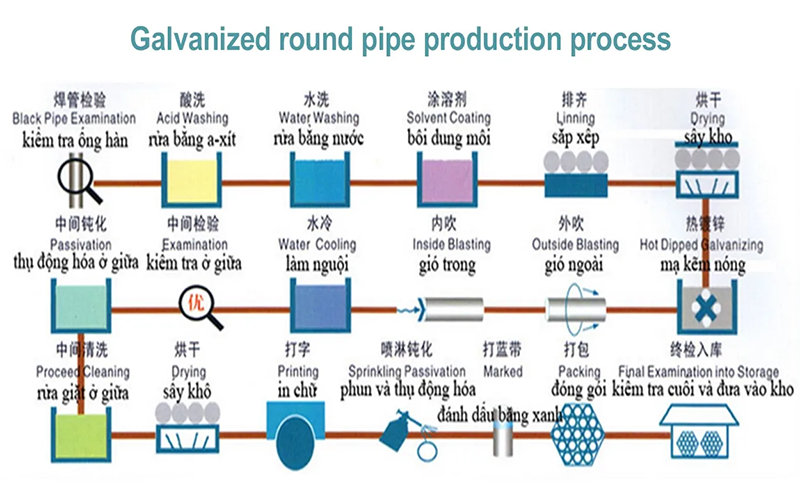

Procedimento di galvanizzazione a immersione calda:

Smaltimento del pezzo → lavaggio → acidificazione → lavaggio → asciugatura immersione nel solvente flussing pre-riscaldamento galvanizzazione a caldo immersa → raffreddamento → finitura → sciacquatura → asciugatura → prova di passivazione

Processo di galvanizzazione a freddo:

Smaltimento chimico → lavaggio → elettrolisi in acqua calda acqua calda → lavaggio → lavaggio → galvanizzazione corrosiva su acciaio zincato → lavaggio → lavaggio → leggero → → lavaggio → asciugatura passivazione

I vantaggi dei tubi galvanizzati sono i seguenti:

In primo luogo, il tubo galvanizzato dopo essere stato trattato con galvanizzazione a immersione calda può essere protetto, e all'interno della cavità del tubo o in qualsiasi altro rivestimento è difficile per la vernice entrare negli angoli, mentre lo zinco può facilmente coprire fino in cima, proteggendo così l'intero tubo galvanizzato.

In secondo luogo, dopo essere stati galvanizzati, i tubi in acciaio galvanizzati hanno un'eccellente resistenza agli impatti e alle abrasioni, poiché la durezza del rivestimento di zinco è superiore alla durezza dell'acciaio, e quindi la resistenza agli impatti e all'usura dopo la galvanizzazione a caldo è abbastanza buona. Inoltre, il principale vantaggio della galvanizzazione è che nel punto angolare il rivestimento di zinco sarà relativamente spesso e avrà una buona tenuta e resistenza all'usura, mentre gli altri rivestimenti sono spesso più sottili e difficili da applicare in questi angoli, rendendoli vulnerabili a danni.

Specifiche:

| descrizione | l Tubo saldatizio galvanizzato | |

| l Grado di acciaio | l Astm a53 Gr.B / ASTM A106 | |

| l Norma | l ASTM A106/A106M;ASTM A53/A53M;API 5L;GB/T 8163-2008;GB/T 8162-2008;BS1387, BS1139,EN39, EN1139, ASTM A53, JIS G3444 | |

| l Materiale | l A106 Classe A, A106 Classe B, A106 Classe C, A53 Classe A, A53 Classe B, API 5L Classe B, 10#, 20#, 45# | |

| l Superficie | l Galvanizzazione a immersione calda; Galvanizzazione elettrolitica; Metodo richiesto dal cliente | |

| il tipo | l 1. Pre-dipinto (zinc: 60-120G/M2) l 2. Galvanizzato a immersione calda (zinc: 120-500G/M2) l 3. Galvanizzato a immersione fredda (zinc: 10-50G/M2) | |

| taglia L | l Spessore del muro | l 1-22mm |

| Diametro Esterno | 21.3mm-610mm | |

| l Tempo di consegna | l Consegna rapida o in base alla quantità dell'ordine. | |

| l Imballo | l Imballo standard per esportazione idoneo al trasporto marittimo, oppure come richiesto. | |

| l Applicazione | trasporto di fluidi; supporto strutturale; HVAC; industria petrolifera e gassiera; attrezzature industriali | |

| contatto | se hai domande, non esitare a contattarmi. | |

| dimensioni del contenitore | 20ft GP: 5898mm(Lunghezza)x2352mm(Larghezza)x2393mm(Altezza) 24-26CBMl l 40ft GP: 12032mm(Lunghezza)x2352mm(Larghezza)x2393mm(Altezza) 54CBMl l 40ft HC: 12032mm(Lunghezza)x2352mm(Larghezza)x2698mm(Altezza) 68CBM |

|

Rapido dettaglio:

1.tubo gi, tubo rotondo in acciaio galvanizzato a immersione calda, tubo in acciaio galvanizzato, tubo saldato in acciaio gi

2.Tubo rotondo in acciaio galvanizzato a immersione calda (HDG), è ampiamente utilizzato in vari settori industriali e edilizi in tutto il mondo.

Il tubo galvanizzato a freddo è galvanizzato elettricamente, la quantità di galvanizzazione è molto bassa, solo 10-50g/m2, la sua resistenza alla corrosione è molto inferiore rispetto al tubo galvanizzato a caldo.

Può essere utilizzato nella costruzione, macchinari, miniere di carbone, industria chimica, elettricità, veicoli ferroviari, industria automobilistica, strade, ponti, container, impianti sportivi, macchinari agricoli, macchinari petroliferi, macchinari di esplorazione e altre industrie manifatturiere.

| Proprietà chimiche % | |||||||||

| Classe A | |||||||||

| C | Mn | P | S | Sì | Cr | Cu | Mo | Ni | V |

| 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Grado B | |||||||||

| C | Mn | P | S | Sì | Cr | Cu | Mo | Ni | V |

| 0.3 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Classe C | |||||||||

| C | Mn | P | S | Sì | Cr | Cu | Mo | Ni | V |

| 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Proprietà meccaniche | |||

| Classe A | Grado B | Classe C | |

| Resistenza alla trazione | 330 | 415 | 485 |

| Resistenza alla Rottura | 205 | 240 | 275 |

Descrizione:

Il tubo saldato galvanizzato si riferisce a un tipo di tubo in acciaio ricoperto da uno strato di zinco attraverso un processo chiamato galvanizzazione.

Il processo di galvanizzazione prevede l'immersione del tubo in acciaio in una vasca di zinco fuso, che forma uno strato protettivo sulla superficie del tubo.

Lo scopo della galvanizzazione dei tubi saldati è quello di fornire resistenza alla corrosione e prolungare la durata del tubo. Lo strato di zinco agisce come una barriera tra l'acciaio e l'ambiente circostante, proteggendo il tubo dalla ruggine e da altre forme di corrosione.

Questo rende i tubi saldati galvanizzati adatti per varie applicazioni, specialmente in settori dove l'esposizione all'umidità o a sostanze corrosive è comune.

Alcuni vantaggi principali dei tubi saldati galvanizzati includono:

1. Resistenza alla corrosione: Il rivestimento in zinco fornisce una eccellente resistenza alla corrosione, rendendo i tubi galvanizzati adatti per applicazioni all'aperto e sotterranee.

2. Durata: La combinazione di acciaio e rivestimento in zinco migliora la resistenza e la durata del tubo, permettendogli di

resistere a condizioni difficili e ad un uso intensivo.

3. Economia: I tubi saldati galvanizzati sono generalmente più economici rispetto ad altre alternative resistenti alla corrosione, rendendoli una scelta economica per vari progetti.

4. Facile installazione: I tubi saldati galvanizzati sono relativamente facili da installare grazie alle loro dimensioni standardizzate e compatibilità

con le staffe e i connettori comunemente utilizzati.

5. Versatilità: I tubi saldati galvanizzati sono disponibili in varie dimensioni e spessori, rendendoli adatti per un ampio ventaglio di applicazioni, inclusi impianti idraulici, costruzioni, agricoltura e progetti industriali.

È importante notare che i tubi saldati galvanizzati hanno limitazioni. Nel tempo, il rivestimento in zinco potrebbe degradarsi o staccarsi,

soprattutto in ambienti altamente corrosivi. Pertanto, ispezioni regolari e manutenzione sono necessarie per garantire la protezione continua del tubo.

Inoltre, quando si lavora con tubi saldati galvanizzati, è importante prendere le debite precauzioni di sicurezza, come l'uso di

equipaggiamento di protezione personale adeguato e l'assicurazione di una ventilazione appropriata, poiché il processo di galvanizzazione può rilasciare fumi che possono essere dannosi se inalati.

Applicazioni:

costruzione, macchinari, miniera di carbone, industria chimica, energia elettrica, veicoli ferroviari, industria automobilistica, autostrade, ponti, container, impianti sportivi, macchinari agricoli, macchinari petroliferi, macchinari di esplorazione ed altre industrie di produzione.

Specifiche:

| Tubo Acciaio Galvanizzato Tondo | |||||||||

| Norma: API 5L, API 5CT, ASTM A53, ASTM A500, GB9711.1 Applicazione: Da utilizzare per il trasporto di gas, acqua e petrolio per le industrie del petrolio e del gas naturale e utilizzare per lo scopo di tubi in acciaio strutturale. Grado principale del tubo in acciaio: GR.A, GR.B, GR.C, Q195, Q235B, Q345B e così via. |

|||||||||

| Pollice | Diametro esterno (mm) | Spessore standard delle pareti | |||||||

| SCH 10WT (mm) | SCH 20WT (mm) | SCH 40WT (mm) | SCH 60WT (mm) | SCH 80WT (mm) | SCH 100WT (mm) | SCH 160WT (mm) | XXS (mm) | ||

| 1/4” | 13.7 | 2.24 | 3.02 | ||||||

| 3/8” | 17.1 | 2.31 | 3.2 | ||||||

| 1/2” | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.5 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.7 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.7 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

| 30" | 762 | 7.92 | 12.7 | ||||||

| 32" | 813 | 7.92 | 12.7 | 17.48 | |||||

| 34" | 863 | 7.92 | 12.7 | 17.48 | |||||

| 36" | 914 | 7.92 | 12.7 | 19.05 | |||||

| 38" | 965 | ||||||||

| 40" | 1016 | ||||||||

| 42" | 1066 | ||||||||

| 44" | 1117 | ||||||||

| 46" | 1168 | ||||||||

| 48" | 1219 | ||||||||

Vantaggio Competitivo:

Abbiamo prezzi competitivi e vantaggi di consegna tempestiva nell'offerta di tubi in acciaio senza saldatura, non solo per i clienti con volumi elevati, ma accettiamo anche ordinazioni personalizzate per campioni, specifiche e requisiti di imballaggio richiesti dai clienti.

Il nostro team amichevole adora sentire le tue notizie!