| 원산지: | 중국 산동 |

| 브랜드 이름: | jinzheng |

| 모델 번호: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grade1、Grade3、Grade4、Grade6、Grade7、Grade8、Grade9、Grade10、Grade11 |

| 인증: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| 최소 주문 수량: | 1 톤 |

| 가격: | $650/톤 |

| 포장 세부사항: | 수출 포장 표준(니론 가방으로 묶음, 나무 상자 또는 요구 사항에 따라) |

| 배송 시간: | 15-20일 |

| 결제 조건: | FOB 30% T/T, 선적 전 70% |

| CIF 30% 사전 결제 및 선적 전 잔액 지불 | |

| 또는 변경 불가능한 100% L/C 현금 against documents | |

| 공급 능력: | 2000 톤/월 |

빠른 세부 사항:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,무선관, 기계용 탄소 및 합금 강관

A333 저온 강관은 석유화학, 천연가스, 화학, 전력, 난방 등 다양한 분야에서 널리 사용됩니다. 그 적용 범위는 매우 넓고 유연합니다. 석유 및 천연가스 송관, 석유화학 장비, 에어컨 시스템 송관, 냉각기, 증기 발생기 등에 사용되며, 또한 기계 가공, 압력 용기, 보일러 제조, 건축용 강구조물, 대형 시설, 전시 센터, 리프트 기계, 조선업, 저장 선반, 인테리어, 교통 시설, 공항 건설, 다리 지지대, 광산 지지대, 입체 주차장, 실외 광고, 피트니스 장비, 차량 제조 등의 산업에서도 사용됩니다.

화학적 요구사항

| 원소 | 구성, % | ||||||||

| 등급 1A | 등급 3 | 4등급 | 등급 6A | 등급 7 | 8등급 | 등급 9 | 등급 10 | 등급 11 | |

| 탄소, 최대 | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| 마랑제 | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 최대 | 0.90 최대 | 0.40-1.06 | 1.15-1.50 | 0.60 최대 |

| 인, 최대 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| 황, 최대 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| 실리콘 | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 최소 | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 최대 |

| 니켈 | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 최대 | 35.0 -37.0 |

| 크롬 | - | - | 0.44-1.01 | - | - | - | - | 0.15 최대 | 0.50 최대 |

| 구리 | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 최대 | - |

| 알류미늄 | - | - | 0.04-0.30 | - | - | - | - | 0.06최대 | - |

| 반듐, 최대 | - | - | - | - | - | - | - | 0.12 | - |

| 콜럼비움, 최대 | - | - | - | - | - | - | - | 0.05 | - |

| 몰리브데넘, 최대 | - | - | - | - | - | - | - | 0.05 | 0.50 최대 |

| 코발트 | - | - | - | - | - | - | - | - | 0.50 최대 |

인장 요구사항

| 1급 | 등급 3 | 등급 6 | 등급 7 | |||||

| psi | Mpa | psi | Mpa | psi | Mpa | psi | Mpa | |

| 인장 강도, 최소 양도 강도, 최소 | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| 종방향 | 횡방향 | 세로 | 횡방향 | 세로 | 횡방향 | 세로 | 횡방향 | |

| 2인치 또는 50mm, (또는 40)에서의 신장률. 최소 %: 기본 최소 신장률 5/16 인치 (8 mm) 이상의 두께에 대한 조각 시험 및 모든 작은 전단면으로 시험된 크기들에 대해 표준 라운드 2인치 또는 50mm 게이지 길이 또는 비례하여 더 작은 크기 게이지 길이를 가진 시험편 직경의 4배(4D)에 해당하는 것이 스트립 시험용으로, 벽두께가 각 1/32인치 [0.8mm] 감소할 때마다 5/16인치 (8mm) 미만인 경우 기본 최소 신장율에서 차감됩니다 다음 백분율만큼 |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| 8등급 | 등급 9 | 등급 10 | 등급 11 | |||||

| psi | Mpa | psi | Mpa | psi | Mpa | psi | Mpa | |

| 인장 강도, 최소 양도 강도, 최소 | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| 종방향 | 횡방향 | 세로 | 횡방향 | 세로 | 횡방향 | 세로 | ||

| 2인치 또는 50mm에서의 신장율, (또는 40). 최소, %:기본 벽 두께 5/16인치 (8 mm) 이상에 대한 최소 신장율 두께로, 띠 시험을 하며 모든 작은 크기는 시험된 후입니다. 전단면에서 표준 원형 2인치 또는 50mm 게이지 길이로 또는 비례적으로 더 작은 크기의 시험체를 사용하여 게이지 길이가 4D(직경의 4배)와 동일합니다. 띠 시험에 대해, 벽 두께가 5/16 인치 (8 mm) 미만일 경우 각각 1/32 인치 [0.8 mm] 당 차감됩니다. 기본 최소 신장율 아래 다음 백분율만큼 감소합니다 |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

설명

1. 제품 간단 소개

저온용 무선배관은 주로 석유, 화학, 천연가스 및 석탄을 원료로 하는 에틸렌, 프로필렌, 요소, 합성 암모니아, N-P-K 복합비료 및 제약 산업의 세척, 정제, 탈황 및 탈지 생산에 사용되며, 또한 저온 장비 제조, 초저온 저장, 초저온 액화 가스 운송 배관 및 파이프 부품에 사용됩니다. 국제 저온용 무선배관 시스템은 ASTM A333/A333M-2011(이하 미 표준)으로 대표되며, 최저 -196℃의 저온 환경에 적합합니다. 현재 전 세계적으로 저온용 무선배관의 생산과 검수는 대부분 미 표준을 사용하며, 국내 설계도 미 표준을 참조합니다. 미 표준 저온 배관의 9개 등급 중 Gr.6는 석유화학 산업과 저온 및 한랭 지역의 유체 운송에 널리 사용되며, 미국과 유럽 시장에서 매년 2만 톤 이상의 수요가 있습니다.

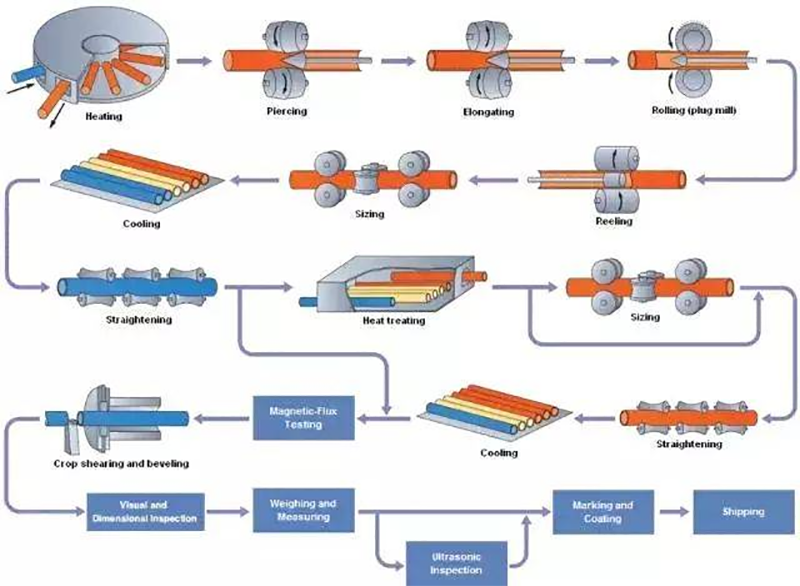

2. 제조 공정

제조 - 튜브는 무逢합 공정 또는 용접 금속을 추가하지 않는 용접 공정으로 제작됩니다. 4등급은 무逢합 공정으로 만들어야 합니다.

열처리

모든 무逢합 및 용접 파이프는 다음 방법 중 하나로 그들의 미세 구조를 통제하기 위해 열처리되어야 합니다.

적어도 1500F (815℃)까지 균일하게 가열하여 긍정적인 열처리를 수행한 후, 대기 냉각하거나 제어된 공기 산소로 구성된 냉각실에서 냉각합니다.

강관은 정화 처리되고, 강철 공장에서 결정된 적절한 회화 온도로 재가열됩니다. 관의 재가열은 핫 프로세싱을 잘 조절하여 핫 포밍 작동 온도를 1550~1750F (845-945°C) 범위 내에 유지하도록 하고, 이후 최초 온도가 적어도 1550°F (845°C) 이상인 제어된 가스 산소로운로에서 냉각됩니다. 이 방법은 비逢합 관 공정에만 적용됩니다.

공장에서 결정한 적절한 환원 온도로 처리되고 재가열됩니다.

주문에 명시된 경우, 시험편은 열처리된 강관에서 채취된 두께 시험 블록에서 절단되며, 스트레스를 해소해야 합니다. 시험 블록은 지정된 온도까지 점진적으로 가열되고, 이 온도에서 지정된 시간 동안 보유된 후 600F (315°C) 이하의 온도로 냉각되어야 합니다. 8등급 강관의 시험 블록은 최소 냉각 속도 300F/h (165℃/h)로 공기 냉각 또는 물 냉각되어야 하며, 600F (315℃) 이하의 온도로 냉각되어야 합니다.

3. 제품의 주요 브랜드 또는 강종

ASTM A333-Grade1、Grade4、Grade6、Grade7、Grade9、Grade10

ASTM A334-Grade1、Grade6、Grade7、Grade9

API 5CT80、L80-1、L803Cr、P110

4. 제품 실시 표준

GSTM 8333、 GSTM 8334、 API SPEC 5CT (9th)

5. 제품 특징

회사는 저온에 강하고 비혈관성이며, 저황 및 저인 고순도 강재와 석회화 처리를 사용하여 강의 저온Brittleness을 효과적으로 줄이고 제품의 충격 인성력을 향상시킬 수 있습니다. 회사는 0 "-100C 냉각 탱크를 보유하고 있어 대량으로 저온 충격 시험을 수행하여 제품의 품질과 안정성을 보장할 수 있습니다.

6. 제품 사용 환경

A333과 A334 저온관은 -45~-195°C 등급의 저온 용기 파이프와 저온 열교환기 파이프에 사용됩니다. 또한 저온 환경에서 유체 전송 파이프로도 사용될 수 있습니다. API5CT 저온 내성 케이싱은 주로 극한의 추운 지역에서의 시추 작업에 사용됩니다. 이 강관은 극저온에서 사용할 수 있으며, 높은 강도, 부식 저항성, 양호한 가공성 및 용접성이 있습니다. 이러한 특성들로 인해 A333GR.6 저온 강관은 석유, 천연가스, 화학 등 다양한 산업 분야에서 널리 사용되고 있습니다.

7. 제품 사양 범위

외경: 16mm~323.9mm; 벽두께: 2.0mm~40.0mm

응용 분야:

석유화학, 천연가스, 화학, 전력, 난방 등 다양한 분야에서 널리 사용됩니다. 그 적용 범위는 매우 넓고 유연하며, 석유 및 천연가스 전송 파이프라인, 석유화학 장비, 에어컨 시스템 파이프라인, 냉각기, 증기 발생기 등에 사용되며, 기계 가공, 압력 용기, 보일러 제조, 건축용 강구조물, 대형 시설, 전시 센터, 리프트 기계, 조선, 저장 선반, 인테리어, 교통 시설, 공항 건설, 다리 지지대, 광산 지지대, 입체 주차장, 실외 광고, 피트니스 장비, 차량 제조 등 다양한 산업에서도 사용됩니다.

사양:

무봉강관의 표준

| API SPEC 5L | |||

| 제품 이름 | 실행 기준 | 크기 (mm) | 강종 코드 / 강등급 |

| 전송 파이프 | Api 5l | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| 제품 이름 | 실행 기준 | 크기 (mm) | 강종 코드 / 강등급 |

| 케이스 | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| 튜빙 | API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| 제품 이름 | 실행 기준 | 크기 (mm) | 강종 코드 / 강등급 |

| 검정 및 핫디핑 아연 도금 원형 스틸 파이프 | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| 고온용 무선 용접 탄소강 관 | Astm a106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| 무선 냉간 압출 저탄소 강열 교환기 및 응축기 관 | ASTM A179 | ø10.3~426x WT1.0~36 | 저탄소 강철 |

| 고압용 탄소강 보일러 관 | ASTM A192 | ø10.3~426 x WT1.0~36 | 저탄소 강철 |

| 무선 냉간 압출 중간 합금 강열 교환기 및 응축관 | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| 무선 중탄소 강 보일러 및 과열기 관 | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| 무선 페라이트 및 오스테나이트 합금 강 보일러, 과열기 및 열교환기 관 | Astm a213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| 기계용 튜브를 위한 무접합 탄소강 및 합금강 | ASTM A333 | ø1/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| 저온용 무접합 및 용접 탄소강 파이프 및 합금강 파이프 | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| 무접합 냉간인출 탄소강 피드워터 히터 튜브 | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| 제품 이름 | 실행 기준 | 크기 (mm) | 강종 코드 / 강등급 |

| 고온용 무선강관 | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| 무선강관 | DIN 1629 \/ DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| 무선강관 | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| 구조용 무선접관 | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| 제품 이름 | 실행 기준 | 크기 (mm) | 강종 코드 / 강등급 |

| 기계 구조용 무선접관 | BS 970 | ø10~762x WT1.0~120 | 탄소강 |

| 보일러 및 열교환기용 무선접관 | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

경쟁 우위:

1. 경량입니다.

이 파라미터는 사각형 강철의 1/5로, 더 나은 무게와 경량화 성능을 가지고 있으며, 사각형 강철보다 가볍고 그 무게는 사각형 강철의 1/5에 불과합니다.

2. 부식 및 고온 저항성.

좋은 부식 저항성과 고온 저항성을 가지고 있으며, 사각형 강철보다 우수합니다. A333은 산, 알칼리, 염 및 대기 환경 부식에 대한 부식 저항성이 있으며, 고온 저항성, 좋은 충격 저항성 및 피로 저항성을 가지고 있어 정기적인 유지 보수가 필요 없으며, 유효 수명은 15년 이상일 수 있습니다.

3, 변형되지 않고 방전 저항.

좋은 방전 특성을 가지고 있으며 일반 강관보다 우수합니다. 무선 관은 기계 장비에서 재사용될 때 높은 탄력성, 기억이 없고 변형되지 않으며 방전 특성이 있습니다. 무선 관은 우수한 기계적 성질을 가지고 있어 가공하기 쉽습니다 등.

친절한 팀이 귀하로부터 연락을 받고 싶어합니다!