| 원산지: | 중국 산동 |

| 브랜드 이름: | Changshengda(CSD) |

| 모델 번호: | Q195/Q235/Q345 SS400 |

| 인증: | API, CE, GS, ISO9001 |

| 최소 주문 수량: | 20 톤 |

| 가격: | 545USD/톤-680USD/톤 |

| 포장 세부사항: | 1. 표준 해양 포장 |

| 2. 고객 요구에 따라 | |

| 포트: | 상하이, 천진, 청도 항구, 필요에 따라 다른 항구를 지정할 수 있습니다. |

| 배송 시간: | 8-14일 |

| 결제 조건: | 신용 카드, T/T |

| 공급 능력: | 100000톤/월 |

| 소재: | ERW:Q235, Q345, 20#, J55, X42~65 등 |

| LASW:Q195,Q235,Q345B,X42,X52,X60,S355JRH,S355J0H,S355J2H 등 |

설명:

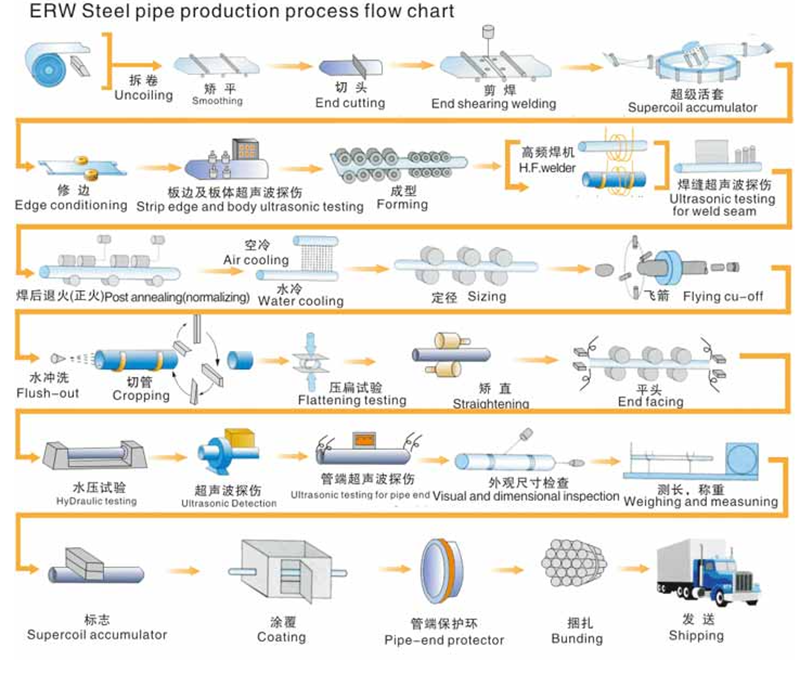

직선 용접 고주파 (ERW)는 용접 방법에 따라 감응 용접과 접촉 용접으로 나뉩니다. 이는 핫롤링 넓은 코일을 원료로 사용하여 사전 구부리기, 연속 성형, 용접, 열처리, 사이징, 교정, 절단 등을 거칩니다. 나선형 공정과 비교하면 용접 부분이 짧고, 치수 정확도가 높으며, 벽 두께가 균일하고, 표면 품질이 좋고, 압력 저항이 높다는 장점이 있습니다. 그러나 단점은 중소 직경의 얇은 벽 파이프만 생산할 수 있으며, 용접 부위에서 회색 반점과 융합 불량이 발생하기 쉽고, 홈 부식 결함이 생길 수 있습니다. 현재 가장 널리 사용되는 분야는 도시 가스, 원유 및 정제유 운송 등입니다.

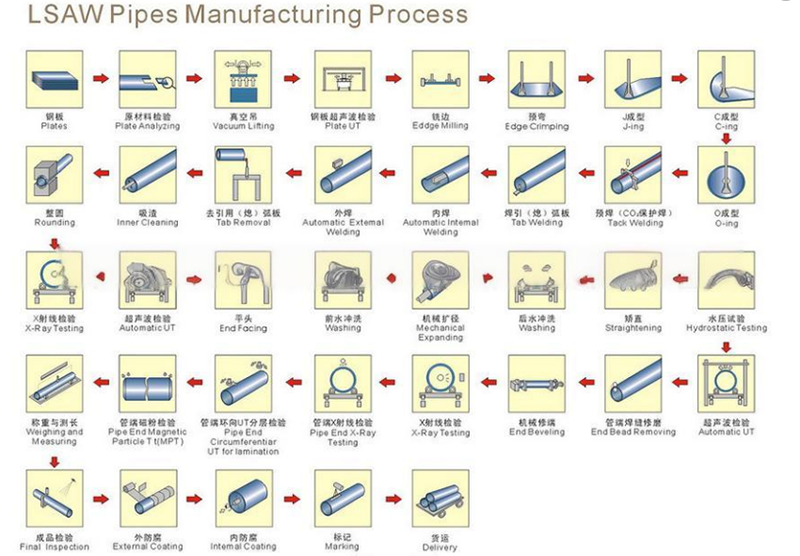

직선 접합부 전기アー크 용접관(LSAW)은 단일 중후판을 원료로 사용하여 금형이나 성형기에서 강판을 눌러(굴려) 성형하고, 양측면 전기アー크 용접 및 직경 팽창 공정을 거쳐 제작됩니다. 그 제품 사양 범위는 넓고 용접부의 인성, 연성, 균일성 및 밀도가 우수하며, 대구경, 두꺼운 파이프벽, 높은 압력 저항, 저온 저항 및 강한 부식 저항 특성을 가지고 있습니다. 고강도, 고인성, 고품질 장거리 유가스 파이프라인을 건설할 때 필요한 대부분의 강관은 대구경이고 두꺼운 벽체를 가진 직선 접합부 전기アー크 용接管입니다. API 표준에 따르면 대규모 유가스 전송 파이프라인에서 고산지대, 해저, 인구 밀집 도시 지역과 같은 1급 및 2급 구역을 통과할 경우 직선 접합부 전기アー크 용接管이 유일하게 지정된 적용 가능한 관종입니다.

다양한 성형 방법에 따라 다음과 같이 분류할 수 있습니다:

UOE 강관: 단일 강판이 가장자리에서 사전湾곡된 후 U 형성, O 형성, 내부 용접, 외부 용접 및 기계적 냉간 팽창 과정을 거칩니다.

JCOE 강관: 즉, "J-C-O-E" 순서로 사전 용접, 성형 및 용접 후 냉간 팽창합니다.

HME 강관: "C-C-O" 방식으로 망치 롤링법에 의해 성형되며, 용접 후 냉간 팽창됩니다.

사양:

| 에브 파이프 | |

| ASTM | ASTM A53 B, ASTM A178, ASTM A252 GR.2, A500, ASTM A513 |

| EN | EN 10204/10217 S235JR,S275JR,S355,S355JR,S355J2H |

| 아피 | API 5L X42/46/52/56/60/70 |

| 탄소강 | ASTM A671,ASTM A672 |

| 합금강 | ASTM A691 |

| OD | 1/2" -24" (21.3mm-610mm) |

| Wt | 1.65mm-20mm |

| 애플리케이션 | 전송용 파이프; OCTG (오일 컨트리 튜브러 goods); 라운드 구조 파이프; 코팅 파이프. |

| Lsaw 파이프 | |||

| 표준 | ASTM 53 ;API Spec 5L;ASTM A252-89; EN10217, EN10219 | ||

| 강종 | API 5L: GR A, GR B, X42, X46, X56, X60, X65, X70ASTM A252 GR 1, GR 2, GR 3ASTM A53: GR A, GR B, GR C, GR DBS 4360: Grade 43, 등급 50EN: S275, S275JR, S355JRH, S355J2H |

||

| 애플리케이션 | 유류/가스/수도용; 전송; 공학용; 해상 프로젝트용. | ||

| 사용 | 외경(mm) | WT(mm) | 길이(미터) |

| 롤러 파이프 | 1200-3800(47.24”-150”) | 12-120 (1⁄2”- 4.7”) | <=3.2 |

| 건설용(파이프杭) | 350-1600(14”- 63”) | 6-60 (1⁄4” -2.36”) | 6-12 |

| 석유 및 가스 파이프라인 | 406-1524(16”- 60”) | 6-40 (1⁄4”-1.57”) | 8-12.1 |

| 위 사양 외에도 고객의 요구에 따라 파이프를 생산할 수 있습니다. | |||

빠른 세부 사항:

설명:

저압 유체 전달 용 직선 조인트 스틸 파이프

직경: 219mm~508mm

벽 두께: 6mm~20mm

표준: GB/T 3091-2008

소재: L245~L690, Q235 등

응용 분야: 물, 가스, 공기, 난방 증기와 같은 저압 유체를 운반하는 용도의 직선 접합 용접 강관에 적합하며 기타 구조물에도 사용됩니다.

미국 표준 직선 접합 용접 강관

직경: 219mm~406mm

벽 두께: 6mm~14mm

표준: ASTM

소재: GrA GrB

응용 분야: 주로 수리 공사, 석유 및 가스 산업, 화학 산업, 전력 산업, 농업 관수, 도시 건설 등에 사용됩니다.

오일 케이싱 및 오일 파이프용 직선 접합 강관

직경 219mm~508mm

벽 두께 6mm~20mm

표준 API-5CT

소재 H40, J55, N80, P110

용도: 석유 케이싱 및 튜빙.

미국 표준 스파이럴 용접 강관

직경 219mm~3520mm

벽 두께 5mm~26mm

표준 ASTM

소재 Gr.A, Gr.B, Gr.C, Gr.1~Gr.11

응용: 주로 수리 프로젝트, 석유 및 가스 산업, 화학 산업, 전력 산업, 농업 관수, 도시 건설 등에서 사용되는 말뚝 파이프에 사용됩니다.

직선 용접 송유관

직경 219mm~508mm

벽 두께 6mm~20mm

표준 API-5L

소재 Gr.B, X42~X100

응용: 석유 및 천연가스 운송에 사용됩니다.

경쟁 우위:

회사는 국제적으로 선진 기술과 설비를 도입하였습니다: 예를 들어 W-FF 성형, 고체 상태 고주파 인덕션 용접, 초음파 결함 탐지, 자속 누출 검출, 그리고 고급 시험 장비들 such as 금속조직 분석, 빅스 하드니스 테스터, 충격 시험기, 스펙트로미터 분석기, 만능 시험기 등 여러 장비들이 있습니다. 설립 이후로 회사는 다양한 국제 인증과 영예로운 자격을 취득했습니다: API 5L, API5CT, ISO9002-2000 압력 파이프 라인 생산 면허, 산업 제품 생산 면허, 중국 석유 및 석화 회원증, 중국 품질 보증서 등이 있습니다. 제품은 남미, 북미, 유럽 연합, 동남아시아 등지에 수출되고 있으며, 전 세계 고객들로부터 오랜 기간에 걸쳐 큰 호평을 받고 있습니다.

친절한 팀이 귀하로부터 연락을 받고 싶어합니다!