| Locus Originis: | Shandong, Sina |

| Nomen Notae: | jinzheng |

| Numerus Moduli: | 16MnDG, 10MnDG, 09DG, 09Mn2VDG, 06Ni3MoDG, ASTM A333-Grade1, Grade3, Grade4, Grade6, Grade7, Grade8, Grade9, Grade10, Grade11 |

| Certificatio: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| Quantitas Ordinis Minimae: | 1 Ton |

| Pretium: | $650/ton |

| Packaging Details: | Standard Exportationis Supellectilis (In fasciculis sacculisque Nylo neminis, casis ligneis vel ut postulatur) |

| Tempus traditionis: | 15-20 dies |

| Termini solucionis: | FOB 30% T/T, 70% ante navagationem |

| CIF 30% praepositio et reliquum ante navagationem solvi debet | |

| aut L/C irrevocabile 100% ad visum | |

| Capacitas Supplicandi: | 2000 Ton/Tons per Mensem |

Brevis Descriptio:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,tubus incontinuus,Tubus Carbonis et Luminum Incontinuus pro Usu Mechanico

Tubus aetherii frigidi A333 utilis latissime in campis petrochimicarum, gas naturalis, chemicarum, potentiae electricae, et calefactionis. Usus eius varii et flexibiles sunt, in oleo et ductibus transmissionis gas naturalis, apparatibus petrochimicis, systematibus aerificationis, tubulis refrigerationis, generatricibus vaporis, sed etiam in machinatione mechanicorum, vasculis pressuris, fabricando caldariis, structura ferrea aedificiorum, locis magnis, centris exhibitionis, machinis elevationis, navium constructione, scaffolding deponendi, decoratione, facilitatibus transportationis, aedificando aërodromorum, sustentaculis pontis, supportibus minarum, garagis tridimensionalibus, advertisementibus exterioribus, apparatibus gymnasticis, et fabricando vehiculorum et aliarum industriae.

Requisitiones Chemicas

| Elementum | Compositio, % | ||||||||

| Gradus 1A | Gradus 3 | Classis 4 | Classis 6A | Classis 7 | Gradus 8 | Classis 9 | Classis 10 | Classis 11 | |

| Carbonum, max | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Manganum | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 max | 0.90 max | 0.40-1.06 | 1.15-1.50 | 0.60 Max |

| Phosphorus, maximus | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Sulfur, maximus | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Silicium | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 minimum | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 max |

| Nickel | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 Max | 35.0 -37.0 |

| Chromium | - | - | 0.44-1.01 | - | - | - | - | 0.15 Max | 0.50 maxime |

| Copper | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 Max | - |

| Aluminium | - | - | 0.04-0.30 | - | - | - | - | 0.06max | - |

| Vanadium, maximus | - | - | - | - | - | - | - | 0.12 | - |

| Columbium, maximus | - | - | - | - | - | - | - | 0.05 | - |

| Molybdenum, maximus | - | - | - | - | - | - | - | 0.05 | 0.50 maxime |

| Cobaltum | - | - | - | - | - | - | - | - | 0.50 maxime |

Requisitiones trahentis

| Prima Classis | Gradus 3 | Sexta Classis | Classis 7 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Vis tensilis, minVis cedens, min | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Longitudina | Transversus | Longitudinal | Transversus | Longitudinal | Transversus | Longitudinal | Transversus | |

| Elongatio in 2 in. aut 50mm, (aut 40). min, %:Fundamentum minimum elongationis pro parietes 5/16 in. (8 mm) et superiores in crassitudo, fascia testes.et pro omnibus parvis dimensionibus probatis in tota sectioneQuando standardis rotundus 2-in. aut 50-mm mensura longitudo aut proportione minor forma specimenum probatorium cum longitudine mensurae aequali 4D (4 vicibus diametri) est utendum in experimentis laminae, detractio pro quoque uno 1/32 unciae [0.8 mm] decremento in crassitudine pariete sub 5/16 uncia (8 mm) a minimo basico elongatione de subsequenti proportione |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| Gradus 8 | Classis 9 | Classis 10 | Classis 11 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Vis tensilis, minVis cedens, min | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Longitudina | Transversus | Longitudinal | Transversus | Longitudinal | Transversus | Longitudinal | ||

| Dilatatio in 2 in. aut 50mm, (aut 40). min, %:Fundamentalis minima dilatatio pro parietibus 5⁄16 in. (8 mm) et superiores in crassitudine, experimenta fasciae. et pro omnibus parvis dimensionibus experimentis in tota sectione Quando rotundus standardis 2-in. aut 50-mm galea longitudo aut proportio minoris magnitudinis specimen cum longitudine mensurae aequali 4D (4 multiplicata per diametrum) est utilizata pro testibus laminearum, deductio pro qualibet 1/32 unciae [0.8 millimetris] decremento infra crassitudinem parietis 5/16 unciae (8 millimetrorum) a minima basica elongatione sequentiumproportionem |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Descriptio

1. Brevis introducio producti

Tubus acieris sine sutura ad temperaturam frigidam praecipue in oleo, chimia, gas naturali et carbonis ligni utitur materiis primis ethyleni, propyleni, ureae, amonis syntheticus, fertilis compositus N-P-K et pharmaceuticae industriae lavandi, purgandi, desulfurandi et detergens productionis, necnon fabricae machinarum frigoris, ultra-frigidarum repositoriorum, transportis ultra-frigidarum liquefactarum gaz tuborum et componentium. Systema internationalis tuborum acieris sine sutura ad temperaturam frigidam per ASTM A333/A333M-2011 (hic infra US standard appellatur), quod aptum est ad frigidum usque ad -196℃. Praesentia, productio et acceptatio tuborum acieris sine sutura ad temperaturam frigidam in orbe plerumque US standard utitur, et designatio domestica etiam referre ad US standard. Inter novem gradus tuborum cryogenici US standard, Gr.6 latissime in industria petrochimica et fluidi transportis in regionibus frigidis et frigidis annuatim utitur, et demanda annua in mercatis US et Europae superat 20,000 t.

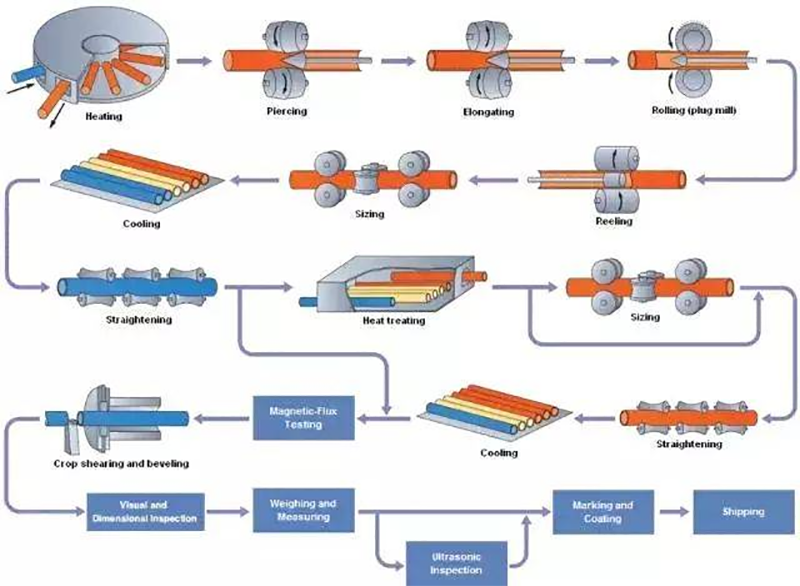

2. Processus fabricationis

Fabricatio - Tubi conficiuntur per processus soderium, qui aut sine iunctura perficiuntur aut metallum impluvium non addunt. Gradus 4 ex materia seamless conficiendus est.

Tractatio caloris

Omnes tubi seamless et soderii calefactione tractandi debent ad eorum microstructuram regendam uno ex sequentibus modis.

Uniformiter ad non minusquam 1500F (815℃) calefacti sunt pro calefactione positiva, deinde refrigeratione in aere vel refrigeratione in camera aeris oxygini controlati.

Tubus ferratus normalizatur et rursum calefacitur ad temperaturam convenientem temperandi, ut a fabbrica ferrea definitur. Bene regulata tubi recalicatio calorem operationis formandi calidum intra rangum formandi calidi 1550 ad 1750F (845-945 ° C) continet, deinde in fornace aeris oxygini controlati refrigeratur cum temperatura initiali non minusquam 1550 (845 ° C). Hic modus tantummodo ad processus tuborum non-suturarum accommodatur.

Tractatur et rursum calefit ad temperaturam temperandam appropriatam ut a fabbrica definitum est.

Cum in ordine specificatum est, specimen ab aliquota crassitiei praebenda est, quae sumitur ex tubo ferreo tractato calido, et debet esse stressus alleviatus. Aliquots gradatim calefaciuntur ad temperaturam specificatam, humidificatae in hac temperatura per tempus specificatum, et deinde refrigerae ad temperamentum non maius quam 600F (315 ° C). Aliquots tuborum ferreorum gradus 8 debent refrigerari in aere vel aqua ad minimum velocitatem refrigerationis 300F/ (165℃/h) ad temperamentum non maius quam 600F (315℃).

3. Praecipua marca aut gradus ferrugineus producti

ASTM A333-Grade1, Grade4, Grade6, Grade7, Grade9, Grade10

ASTM A334-Grade1, Grade6, Grade7, Grade9

API 5CT80, L80-1, L803Cr, P110

4. Normae implementationis productorum

GSTM 8333, GSTM 8334, API SPEC 5CT (9th)

5. Caracteristica producti

Firma resistit frigori et vasculorum carens; usus fit aere alto purissimo cum sulphure et phosphoro minimo ac tractamento calcificationis, quod efficaciter potest fragilitatem frigidae ferri reducere et impactum tenacitatis productorum meliorare. Apud societatem est refrigerium minus 100C, quod perfrui potest experimentis impactus frigidi in partibus ad qualitatem et stabilitatem productorum conservandam.

6. Environnementus usus producti

Tubuli cryogenici A333 et A334 utuntur pro tubulis vasorum cryogenorum graduum -45-195C et pro tubulis commutatorum caloris cryogenici. Possunt etiam uti pro tubulis transportis fluidorum in ambientibus frigidis. Custodia API5CT resistentis frigori utitur praecipue pro forandi puteis in regionibus frigidissimis. Tubus ferratus potest uti in frigoribus extremis, sed etiam habet vim altam, resistens corruptioni, bonam facilitatem fabricandi et coniungendi. Hae proprietates faciunt tubum ferreum frigoris A333GR.6 late uti in campis industrialibus olei, gasis naturalibus, et chimicis.

7. Ambitus specificus producti

Diameter externus: 16mm~323.9mm; Crassitudo parietis: 2.0mm~40.0mm

Applicationes:

Late frequentur in petrochimico, naturali gasu, chimico, electrico potestate, calefactione et aliis campis. Amplum spectrum applicationum, flexibile, In oleo, naturae gasus ductibus, petrochimicis machinis, aerificationis systematis ductibus, refrigerantibus, vaporariis generatricibus, sed etiam utendum in mechanicis processibus, vasculis pressurae, fabrica fornacium, aedificia structurae ferreae, magnis locis, exhibitionibus centris, machinamentis levantibus, navium constructione, rebus servantibus, decoratione, transportis facilitatibus, aeroporto constructione, ponte sustentatione, mina sustentatione, garagio tridimensionali, publice advertisemente, gymnastico apparatu, Fabricatione vehiculorum et aliis industriis3

Specificationes:

Normae tubi sine sutura

| API SPEC 5L | |||

| Productum Nomen | Standard Exsecutionis | Dimensio (mm) | Codex Ferri / Gradus Ferri |

| Tubi Lineares | API 5L | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| Productum Nomen | Standard Exsecutionis | Dimensio (mm) | Codex Ferri / Gradus Ferri |

| Theca | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubus | API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM \/ ASME | |||

| Productum Nomen | Standard Exsecutionis | Dimensio (mm) | Codex Ferri / Gradus Ferri |

| Nigri et Calido-Immersi Zinco-Restituti Tubi Sine Sagittis Ferri | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Tubi Sine Sagittis Erei Carbonis ad Servitium Alti Caloris | Astm a106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Tubi Sine Sagittis Frigida-Tractati Reiecti Ferri Inferioris Carbonis ad Commutatorem Caloris et Condensatorem | ASTM A179 | ø10.3~426x WT1.0~36 | Ferrum carbonicum parvum |

| Tubuli Induti Carbonis Sine Saginatu pro Alti Pressione | ASTM A192 | ø10.3~426 x WT1.0~36 | Ferrum carbonicum parvum |

| Tubuli Induti Frigoris et Condensatorii ex Materia Ferrea Intermedia sine Saginatu | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Tubuli Induti Medii Carbonis et Tubuli Supercalefacti sine Saginatu | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Tubuli Ferritici & Austenitici Alloy Steel Caloris, Superheater & Heat-Exchanger sine Iuncturis | ASTM A213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Ferrum Carbonis et Alloy Steel sine Iuncturis pro Usu Mechanico | ASTM A333 | ø1\/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Tubuli Ferri Carbonis & Alloy Steel cum Iuncturis et sine Iuncturis pro Usu in Frigore Basso | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Tubuli Caloriferi Aquae Alimentariae ex Aciere Carbonico Frigido Extruso sine Juntura | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Productum Nomen | Standard Exsecutionis | Dimensio (mm) | Codex Ferri / Gradus Ferri |

| Tubuli ex Aciere sine Juntura pro Temperatura Elevata | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Tubus ferrugineus sine iunctura | DIN 1629 \/ DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Tubus ferrugineus sine iunctura | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Tubus Indissolubilis Ferri ad Usus Structurales | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| Productum Nomen | Standard Exsecutionis | Dimensio (mm) | Codex Ferri / Gradus Ferri |

| Tubus Indissolubilis Ferri ad Structuras Machinarum | BS 970 | ø10~762x WT1.0~120 | Carbon chalybe |

| Tubus Indissolubilis Ferri ad Calidarios et Commutatores Caloris | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Comperativa Commoditas:

1. Levis ponderis.

Parametri est 1/5 quadrati ferri, itaque meliorem leviaetatem habet, levior quam ferrum quadratum, et pondus eius est tantum 1/5 quadrati ferri.

2. Resistentia ad corrosionem et altam temperaturam.

Habet bonam resistentiam ad corrosionem et altam temperaturam, meliorem quam quadrata ferrum, A333 resistentia ad acidum, alkali, salinum et atmosphaerico ambiente corruptionem, altam temperaturam sustinet, bonam resistenciam impactionis et fatigationis habet, non eget cura periodica, efficax vita usus potest esse plus quam 15 annos.

3, nullum deformationem et anti-staticum.

Habet bonas proprietates anti-staticas, meliores quam communia ferri tubi, tubi sine iuncturis alta elasticitate sunt, in machinis reutilizantur, nulla memoria, nulla deformatio, et anti-staticum, tubi sine iuncturis excellentes proprietates mechanicas habent, facile machinantur, etc.

Nostra amica turma te audire amat!