| ທີ່ມາ: | ຊັນດອງ, ປະເທດຈີນ |

| ຊື່ເຫລົ່າ: | jinzheng |

| ເລກທີ່ຂອງມື້ແບບ: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grade1、Grade3、Grade4、Grade6、Grade7、Grade8、Grade9、Grade10、Grade11 |

| ການສັງຊົງ: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| ຈຳນວນສັ່ງຊື້ຕ່ຳສຸດ: | 1 ໂຕນ |

| ລາຄາ: | $650/ຕຸນ |

| ລາຍລະອຽດການເ泰国: | ສະຖານະການເປົ້າຂອງການອອກຂາຍ (ໃນຮູບແບບຫຼຸມ尼龙头, ກາແພກไม້, ຫຼືຕາມທີ່ຕ້ອງການ) |

| ເວລາຈັດສົ່ງ: | 15-20 ມື້ |

| ສິນທີ່ຈ່າຍ: | FOB 30%T/T, 70% ກ່ອນຈະສົ່ງສິນຄ້າ |

| CIF 30% ອະນຸຍາດລ່ວງໜ້າ ແລະ ລາຍໄດ້ທີ່ເຫຼົ່າງຈະຕ້ອງຈ່າຍກ່ອນສົ່ງສິນຄ້າ | |

| ຫຼຶ່ງ 100% L/C ອັນສົມບູນ ທີ່ເຫຼົ່າງກຳນົດເຫັນ | |

| ຄວາມສາມາດໃນການສະໜອງ: | 2000 ຕຸນ/ຕຸນ ມື້ລະເດືອນ |

ລາຍລະອຽດສັ້ນๆ:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984, ປ່ຽນແປງ, ປ່ຽນແປງ Carbon ແລະ Alloy Steel ສຳລັບ Mechanical Tubing

ท่อเหล็กคาร์บอนอุณหภูมิต่ำ A333 ถูกใช้อย่างแพร่หลายในด้านปิโตรเคมี ก๊าซธรรมชาติ เคมี พลังงานไฟฟ้า การทำความร้อน และสาขาอื่น ๆ อีกมากมาย มีการประยุกต์ใช้งานหลากหลายและยืดหยุ่น ในท่อนำส่งน้ำมันและก๊าซธรรมชาติ อุปกรณ์ปิโตรเคมี ระบบท่อนำของเครื่องปรับอากาศ เครื่องแลกเปลี่ยนความร้อน เครื่องสร้างไอน้ำ นอกจากนี้ยังใช้ในกระบวนการกลึงชิ้นส่วนเครื่องจักร ภาชนะที่อยู่ภายใต้แรงดัน การผลิตหม้อไอน้ำ การสร้างโครงสร้างเหล็กสำหรับอาคาร สถานที่ขนาดใหญ่ ศูนย์แสดงสินค้า เครื่องยก การสร้างเรือ การวางโครงเหล็กเพื่อเก็บของ การตกแต่ง สิ่งอำนวยความสะดวกในการขนส่ง การก่อสร้างสนามบิน การรองรับสะพาน การรองรับเหมืองแร่ การจอดรถสามมิติ โฆษณากลางแจ้ง อุปกรณ์ออกกำลังกาย และการผลิตยานพาหนะ

ข้อกำหนดทางเคมี

| Element | องค์ประกอบ, % | ||||||||

| ระดับ 1A | ระดับ 3 | ລະດັບ 4 | ระดับ 6A | ระดับ 7 | ຊັ້ນ 8 | ระดับ 9 | ระดับ 10 | ระดับ 11 | |

| ການໂຄນ,max | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| ມັງກະນີສ | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 max | 0.90 max | 0.40-1.06 | 1.15-1.50 | 0.60 max |

| Phosphorus, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Sulfur, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| ຊິລິໂຄນ | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 ນາທີ່ຕ່້າຍສຸດ | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 ຕົວສູງສຸດ |

| ນິເກິລ | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 ທົ່ວຍ | 35.0 -37.0 |

| Chromium | - | - | 0.44-1.01 | - | - | - | - | 0.15 ທົ່ວຍ | 0.50 ທົ່ວຍ |

| ทองแดง | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 ທົ່ວຍ | - |

| ອາລູມິນຽມ | - | - | 0.04-0.30 | - | - | - | - | 0.06 ລູ້ຍ | - |

| ເວດນິຍຸມ, ລູ້ຍ | - | - | - | - | - | - | - | 0.12 | - |

| ຄອລູມບຽມ, ລູ້ຍ | - | - | - | - | - | - | - | 0.05 | - |

| ມໍລີເບດຳ, ລູ້ຍ | - | - | - | - | - | - | - | 0.05 | 0.50 ທົ່ວຍ |

| Cobalt | - | - | - | - | - | - | - | - | 0.50 ທົ່ວຍ |

ຂໍ້ມູນກ່າວແຫຼງ

| ຊະນິດ 1 | ระดับ 3 | ຊະນິດ 6 | ระดับ 7 | |||||

| pSI | MPa | pSI | MPa | pSI | MPa | pSI | MPa | |

| ພື້ນສົງກ່າວແຫຼງ, ລູ້ຍ ກັບ ພື້ນສົງກ່າວ, ລູ້ຍ | 55 000 30 000 | 380205 | 65 000 35 000 | 450240 | 60 00035 000 | 415240 | 65 000 35 000 | 450 240 |

| ແຈ້ງຍາວ | Transwerse | ຍາວstrpos | Transwerse | ຍາວstrpos | Transwerse | ຍາວstrpos | Transwerse | |

| ການຍຸດຕົວໃນ 2 ປຸ່ມ. ຫຼື 50mm, (ຫຼື 40). ໜ້ອຍສຸດ, %: ການຍຸດຕົວພື້ນຖານໜ້ອຍສຸດເພື່ອ ແຜນ 5/16 in. (8 mm) ແລະຫຼາຍກວ່າໃນ ຄວາມໜັງ, ຕຳແໜ່ງທີ່ສອບສວນ. ແລະເພື່ອທັງໝົດຂົນໜ້ອຍ ຊະນະທີ່ສອບສວນໃນເຂດປຸ່ມເຕັມເມື່ອ ສະຖານະໜ້າ້ 2-in. ຫຼື 50-mm gage lengthy ຫຼືຂະໜາດນ້ອຍກວ່າທີ່ສຳພັນ ຕัวຢາງການສອບສວນດ້ວຍຄ່າວັດໄວທີ່ ເทົ່າກັບ 4D (4 ຄັນແຫວນ) ແມ່ນ ໃຊ້ສຳລັບການສອບສວນພາຍໃນ, ການຫຼຸດລົງ ເປັນຈຳນວນ 1/32 in. [0.8 mm] ເປັນການຫຼຸດລົງ ຂອງຄວາມຫຼັບຫຼຸດຕໍ່ລົງມາຫຼັງ 5/16 in. (8 mm) ຈາກຄ່າຄຸນຄ່າຕ່ຳສຸດຖືກຕ້ອງ ຂອງປະເ<this>ສົນດັ່ງຕໍ່ໄປນີ້ |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| ຊັ້ນ 8 | ระดับ 9 | ระดับ 10 | ระดับ 11 | |||||

| pSI | MPa | pSI | MPa | pSI | MPa | pSI | MPa | |

| ພື້ນສົງກ່າວແຫຼງ, ລູ້ຍ ກັບ ພື້ນສົງກ່າວ, ລູ້ຍ | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 000 35 000 | 450 240 |

| ແຈ້ງຍາວ | Transwerse | ຍາວstrpos | Transwerse | ຍາວstrpos | Transwerse | ຍາວstrpos | ||

| ການຍຸດຕົວໃນ 2 ປຸ່ມ. ຫຼື 50mm, (ຫຼື 40). ຕ່ຳໜີ, %:ພື້ນຖານ ຕ່ຳໜີການຍຸດຕົວສํາລັບແຜນໜ້າ 5/16 ປຸ່ມ. (8 mm) ແລະເທົ່ານັ້ນຂຶ້ນໄປ ໃນຄວາມໜັງ,ການສອບສວນແຜນ.ແລະສํາລັບທັງໝົດຂະໜາດນ້ອຍທີ່ຖືກສອບສວນໃນ ເ tud ທີ່ມາດຕະຖານ 2 ປຸ່ມ. ຫຼື 50-mm gage ຄວາມຍ້າຍ ຫຼື ຄວາມປະກອບນ້ອຍກວ່າທີ່ສົງສອງກັບ ຄວາມຍ້າຍຂອງເຄື່ອງວັດແມ່ນ 4D (4ເທີງຫຼັງຂອງເສັ້ນຜານ) ແມ່ນ ໃຊ້. ສໍາລັບການສົງສອງແຖວ, ການຫຼຸດລົງຂອງຕໍ່ 1/32 in. [0.8 mm] ເພີ່ມຈາກຄວາມໜັງນ້ອຍກວ່າ 5/16 in. (8 mm) ຈາກຄວາມຍ້າຍຕ່ຳສຸດພື້ນຖານຂອງ ສ່ວນ百ທີ່ໄດ້ຮັບ |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

ຄະແນນ

1. ເນື້ອງານສະນັບສະໜູນສິນຄ້າ

ท่อเหล็กกล้าไร้ตะเข็บอุณหภูมิต่ำใช้งานหลักในอุตสาหกรรมน้ำมัน ก๊าซธรรมชาติ เคมี และถ่านหินเป็นวัตถุดิบสำหรับการผลิตเอทิลีน โพรพิลีน ยูเรีย แอมโมเนียสังเคราะห์ ปุ๋ยผสม N-P-K และอุตสาหกรรมเภสัชกรรม เช่น การล้าง ฟอก การกำจัดกำมะถัน และการล้างไขมัน นอกจากนี้ยังใช้ในการผลิตอุปกรณ์อุณหภูมิต่ำ คลังเก็บความเย็นอุณหภูมิต่ำ การขนส่งก๊าซเหลวอุณหภูมิต่ำ และชิ้นส่วนท่อเหล็ก ในระบบท่อเหล็กกล้าไร้ตะเข็บอุณหภูมิต่ำระหว่างประเทศ ASTM A333/A333M-2011 (ต่อไปนี้จะเรียกว่ามาตรฐานอเมริกา) เป็นที่ยอมรับสำหรับสภาพแวดล้อมอุณหภูมิต่ำถึง -196℃ ในปัจจุบัน การผลิตและการยอมรับของท่อเหล็กกล้าไร้ตะเข็บอุณหภูมิต่ำทั่วโลกส่วนใหญ่ใช้มาตรฐานอเมริกา และการออกแบบภายในประเทศก็อ้างอิงตามมาตรฐานอเมริกาเช่นกัน หนึ่งในเก้าเกรดของท่ออุณหภูมิต่ำตามมาตรฐานอเมริกา Gr.6 มีการใช้งานอย่างแพร่หลายในอุตสาหกรรมปิโตรเคมีและขนส่งของไหลในเขตอุณหภูมิต่ำและเขตหนาว โดยความต้องการประจำปีในตลาดสหรัฐฯ และยุโรปมากกว่า 20,000 ตัน

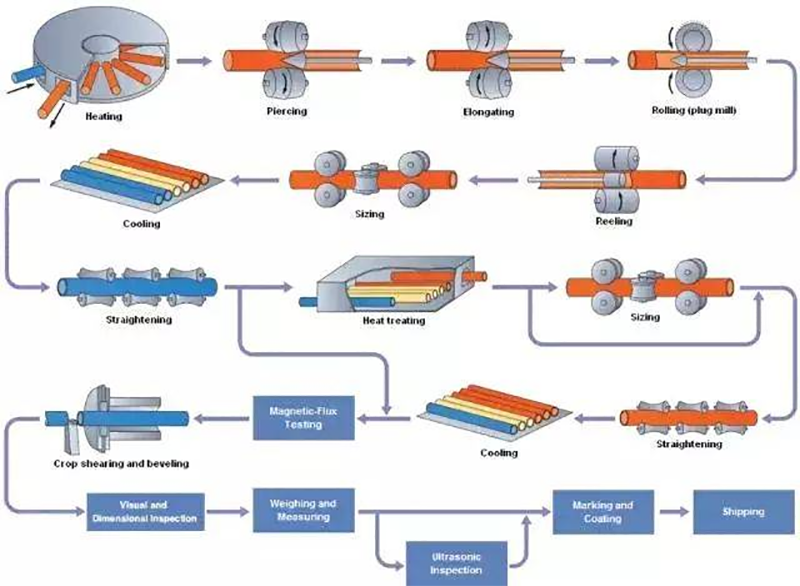

2. ການຜະລິດ

ການຜະລິດ - ເຫຼືອງທີ່ເຮັດຂຶ້ນໂດຍວິທີ່ສວນແຈກທີ່ບໍ່ມີຊໍ່ ຫຼືບໍ່ເພີ່ມເມື່ອງຕັ້ງ. ລະດັບ 4 ຖືກເຮັດໂດຍວິທີ່ບໍ່ມີຊໍ່.

ການດຳເນີນການຮ້ອນ

ທຸກຄັ້ງທີ່ມີເຫຼືອງບໍ່ມີຊໍ່ ແລະ ເຫຼືອງທີ່ມີຊໍ່ ທັງໝົດຕ້ອງຖືກປ່ຽນແປງອຸນຫະພູມເພື່ອຄຳນວນສານພິບັດຂອງພວກມັນໂດຍ ອີງໃສ່ ຕຳຫຼວດໃດໆ ໃນຕໍ່ໄປນີ້.

ຖືກຮ້ອງອຸນຫະພູມເທົ່າກັນ ບໍ່ໜ້ອຍກວ່າ 1500F (815℃) ສໍາລັບການປ່ຽນແປງອຸນຫະພູມທີ່ຖືກຕ້ອງ, ແລະ ລົງມາຫຼັງຈາກນັ້ນ ຫຼັງຈາກນັ້ນ ມັນຈະຖືກລົງອາກາດ ຫຼື ລົງໃນຫ້ອງລົງອາກາດຂອງເຄື່ອງເຮັດອາກາດທີ່ມີການຄຳນວນ.

ເຫຼືອງເหลືອງເປັນເຫຼືອງທີ່ຖືກນັບແລະ ລົງມາຫຼັງຈາກນັ້ນ ມັນຈະຖືກລົງອາກາດ ໃນເຄື່ອງເຮັດອາກາດທີ່ມີການຄຳນວນ ຂຶ້ນກັບອຸນຫະພູມເລີ່ມຕົ້ນ ບໍ່ໜ້ອຍກວ່າ 1550 (845 ° C). ຕຳຫຼວດນີ້ແມ່ນເພີ່ງແຕ່ສຳລັບການປະຕິບັດທີ່ບໍ່ມີຊໍ່.

ມັນຖືກຈັດການແລະເຮັດໃຫ້ອຸນຫະພູມສົງຄວາມເປັນທີ່ເປັນສະເພາະຂອງອຸນຫະພູມການສົງຄວາມທີ່ໄດ້ຖືກຕັ້ງໂດຍສະໜັກງານ.

ເມື່ອມີການກຳນຍໃນບິນສັ່ງ, ຂ້າງເລີຍຈະຖືກຕັດຈາກແຜນສຳລັບການສອບສວນຄວາມລັບ, ທີ່ເອົາມາຈາກທ່ອງເຫຼັ້ງທີ່ໄດ້ຮັບການສົງຄວາມ, ແລະຈະຖືກເຫຼີກຄວາມ. ເຊິ່ງແຜນສຳລັບການສອບສວນຈະຖືກເຮັດອຸນຫະພູມເພີ່ມຂຶ້ນເຖິງອຸນຫະພູມທີ່ກຳນຍ, ກັບຄວາມສົ່ງສຳລັບເວລາທີ່ກຳນຍ, ແລະຫຼັງຈາກນັ້ນຈະຖືກຫຼັງອຸນຫະພູມເຖິງຕົ້ນກວ່າ 600F (315 ° C). ເສັ້ນທີ່ມີຄວາມແຂງແຂງ 8 ຈະຖືກຫຼັງໂດຍການຫຼັງອາກາດຫຼັງຈາກການຫຼັງນ້ຳຢ່າງໜ້ອຍ 300F/ (165℃/h) ເຖິງອຸນຫະພູມທີ່ຕົ້ນກວ່າ 600F (315℃).

3. ປະເທດຫຼັກຫຼາຍຫຼືຄະແນນເຫຼັ້ງຂອງສິນຄ້າ

ASTM A333-Grade1、Grade4、Grade6、Grade7、Grade9、Grade10

ASTM A334-Grade1、Grade6、Grade7、Grade9

API 5CT80、L80-1、L803Cr、P110

4. ລາຍລະອຽດການປະຕິບັດຂອງສິນຄ້າ

GSTM 8333、 GSTM 8334、 API SPEC 5CT (9th)

5. ອຸປະກອນຂອງສິນຄ້າ

ບໍລິສັດມີຄວາມຕ້ອງການຕໍ່ອຸນຫະພູມຕ່ຳແລະບໍ່ມີເສັ້ນເລືອດ ການໃຊ້ເหลືອກທີ່ມີຄຸນສົມປະສົບຕ່ำ (low sulfur) ແລະຄຸນສົມຟົສໂພຣສ (low phosphorus) ແລະການຈັດການຄວາມເຄື່ອນໄຫວຂອງເຄື່ອງ (calcification treatment) ບໍ່ສາມາດເພີ່ມຄວາມແຂງແຮງຂອງເหลືອກໃນອຸນຫະພູມຕ່ຳ ແລະເພີ່ມຄວາມແຂງແຮງຂອງສິນຄ້າ. ບໍລິສັດມີຖື່ນຫຼັງ 0 "-100C, ທີ່ສາມາດເຮັດການສອບສວນຄວາມແຂງແຮງໃນອຸນຫະພູມຕ່ຳ ເພື່ອສົ່ງຜ່ານຄຸນສົມແລະຄວາມສະຖິຕິຍາຂອງສິນຄ້າ.

6. ປະເທດທີ່ໃຊ້ສິນຄ້າ

ท่อไครโอเจนิก A333 และ A334 ใช้สำหรับท่อถังบรรจุไครโอเจนิกเกรด -45-195C และท่อแลกเปลี่ยนความร้อนไครโอเจนิก นอกจากนี้ยังสามารถใช้เป็นท่อขนส่งของเหลวในสภาพแวดล้อมอุณหภูมิต่ำได้อีกด้วย ท่อเคสต้านทานอุณหภูมิต่ำ API5CT ส่วนใหญ่จะใช้สำหรับการเจาะบ่อน้ำมันในพื้นที่หนาวเย็นมาก ท่อเหล็กสามารถใช้งานได้ที่อุณหภูมิต่ำมาก มีความแข็งแรงสูง ต้านทานการกัดกร่อน มีความสามารถในการประมวลผลและการเชื่อมที่ดี คุณสมบัติเหล่านี้ทำให้ท่อเหล็กอุณหภูมิต่ำ A333GR.6 ถูกใช้อย่างแพร่หลายในอุตสาหกรรมน้ำมัน ก๊าซธรรมชาติ เคมี และอื่น ๆ

7. ช่วงข้อมูลจำเพาะของผลิตภัณฑ์

เส้นผ่าศูนย์กลางภายนอก: 16mm~323.9mm; ความหนาของผนัง: 2.0mm~40.0mm

ແອັບພລິເຄຊັນ:

ນໍາໃຊ້ຢ່າງກວ້າງຂວາງໃນທາດແຮ່ທາດ, ອາຍແກັສ ທໍາ ມະຊາດ, ເຄມີ, ພະລັງງານໄຟຟ້າ, ການເຮັດຄວາມຮ້ອນແລະຂົງເຂດອື່ນໆ. ການນໍາໃຊ້ທີ່ກວ້າງຂວາງ, ມີຄວາມຍືດຫຍຸ່ນ, ໃນນ້ໍາມັນ, ທໍ່ສົ່ງແກັສທໍາມະຊາດ, ອຸປະກອນ petrochemical, ທໍ່ລະບົບອາກາດປັບ, coolers, ເຄື່ອງຜະລິດອາຍ, ແຕ່ຍັງຖືກນໍາໃຊ້ໃນການປຸງແຕ່ງກົນຈັກ, ຖັງຄວາມກົດດັນ, ການຜະລິດເຄື່ອງປັ່ນປ່ວນ, ການກໍ່

ລາຍລະ💬💬💬xing:

ສະຖານະຂອງປີ້ນເຊື້ອທີ່ບໍ່ມີໜ້າແຍກ

| API SPEC 5L | |||

| ຊື່ສິນຄ້າ | ສະຖານະການດຳເນີນງານ | ຂະ ຫນາດ (ມມ) | ລະຫັດເหลືອງ / ລະດັບເหลືອງ |

| ທໍາອິດປີ້ນ | API 5L | ø10.3 ~ 1200xWT1.0 ~ 120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| ຊື່ສິນຄ້າ | ສະຖານະການດຳເນີນງານ | ຂະ ຫນາດ (ມມ) | ລະຫັດເหลືອງ / ລະດັບເหลືອງ |

| ຄຸງ | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| ທູບ | API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| ຊື່ສິນຄ້າ | ສະຖານະການດຳເນີນງານ | ຂະ ຫນາດ (ມມ) | ລະຫັດເหลືອງ / ລະດັບເหลືອງ |

| ท่อเหล็กกล้าไร้ตะเข็บเคลือบสีดำและชุบสังกะสีร้อน | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| ท่อเหล็กกล้าคาร์บอนไร้ตะเข็บสำหรับใช้งานอุณหภูมิสูง | Astm a106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| ท่อแลกเปลี่ยนความร้อนและท่อกลั่นชนิดดึงเย็นจากเหล็กกล้าคาร์บอนต่ำไร้ตะเข็บ | ASTM A179 | ø10.3~426x WT1.0~36 | ແຫຼງເຟີຕ່ຳ |

| ท่อหม้อไอน้ำเหล็กกล้าคาร์บอนไร้ตะเข็บสำหรับใช้งานแรงดันสูง | ASTM A192 | ø10.3~426 x WT1.0~36 | ແຫຼງເຟີຕ່ຳ |

| ທ່າວິເຄື້ອມແຫນວສີ່ລູກສະຫຼຸບໂຕເປັນພິດແຫ່ງສາຍແຫຼວຂະຫຍາຍແລະແຫ່ງຊົ່ງເຄື່ອນໄຫວ | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| ທ່າວິເຄື້ອມແຫນວສີ່ລູກສະຫຼຸບເປັນພິດແຫ່ງສາຍແຫຼວຂະຫຍາຍແລະແຫ່ງຊົ່ງເຄື່ອນໄຫວ | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| ທ່າວິເຄື້ອມແຫນວສີ່ລູກສະຫຼຸບແລະເປັນພິດແຫ່ງສາຍແຫຼວຂະຫຍາຍແລະແຫ່ງຊົ່ງເຄື່ອນໄຫວ | ASTM A213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| ເສັ້ນແຫວງເຄື່ອງຂັດທາງການແລະເສັ້ນແຫວງເຄື່ອງຂັດທາງປະສົມ | ASTM A333 | ø1/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| ເສັ້ນແຫວງເຄື່ອງຂັດທາງການແລະເສັ້ນແຫວງເຄື່ອງຂັດທາງປະສົມທີ່ໃຊ້ໄດ້ໃນອຸນຫະພູມຕ່ຳ | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| ເສັ້ນແຫວງເຄື່ອງຂັດທາງການທີ່ຖືກແຈກອອກໂດຍຫຼິ້ນອົບຮົມ | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| ຊື່ສິນຄ້າ | ສະຖານະການດຳເນີນງານ | ຂະ ຫນາດ (ມມ) | ລະຫັດເหลືອງ / ລະດັບເหลືອງ |

| ท่อเหล็กไร้ตะเข็บสำหรับอุณหภูมิสูง | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| ท่อเหล็กไร้ตะเข็บ | DIN 1629 \/ DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| ท่อเหล็กไร้ตะเข็บ | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| ท่อเหล็กไร้ตะเข็บสำหรับโครงสร้าง | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| ຊື່ສິນຄ້າ | ສະຖານະການດຳເນີນງານ | ຂະ ຫນາດ (ມມ) | ລະຫັດເหลືອງ / ລະດັບເหลືອງ |

| ท่อเหล็กไร้ตะเข็บสำหรับโครงสร้างเครื่องจักร | BS 970 | ø10~762x WT1.0~120 | ເຫຼັກກົ້າກາກບອນ |

| ท่อเหล็กไร้ตะเข็บสำหรับหม้อไอน้ำและแลกเปลี่ยนความร้อน | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

ຂໍ້ດີໃນການແຂ່ງຂັນ:

1. ໜູ້ຍນ້ອຍ.

ຄວາມສະພາບແມ່ນ 1/5 ຂອງເหลືກຫຼາຍຂ້າງ, ດັ່ງນັ້ນມັນມີຄວາມໄມ້ແລະໜູ້ຍນ້ອຍດີກວ່າ, ເบาກວ່າເหลືກຫຼາຍຂ້າງ, ແລະໝົດນ້ອຍກວ່າ 1/5 ຂອງເລືກຫຼາຍຂ້າງ.

2. ອຸ່ນຮ້ອນແລະຕົວຕໍ່ຕ້ານການເສຍ.

ມັນມີຄວາມຕໍ່ຕ້ານການເສຍທີ່ດີ, ດີກວ່າເລືກຫຼາຍຂ້າງ, A333 ຕໍ່ຕ້ານການເສຍໂດຍເຄິ່ງ, ເຫມົາ, ເຄື່ອງແລະສະພາບແວດລ້ອມ, ອຸ່ນຮ້ອນ, ຄວາມຕໍ່ຕ້ານການປະສົມແລະຄວາມເຈັບ, ບໍ່ຕ້ອງການປ້ອມປົມທຸກລົດ, ປະຊາວິທະຍະໃຊ້ສາມາດຖືກ 15 ປີກວ່າ.

3, ບໍ່ມີການປ່ຽນແບບແລະຕົວຕໍ່ຕ້ານສະເພາະ.

ມັນມີຄວາມຕໍ່ຕ້ານສະເພາະທີ່ດີ, ດີກວ່າເລືກຫຼາຍຂ້າງທົ່ວໄປ, ເຫມືອງເຄື່ອງທີ່ບໍ່ມີຄວາມຈິງ, ພື້ນຖານ, ບໍ່ມີການປ່ຽນແບບ, ແລະຕົວຕໍ່ຕ້ານສະເພາະ, ເຫມືອງເຄື່ອງທີ່ບໍ່ມີຄວາມຈິງມີຄວາມສະພາບທີ່ດີ, ສະຫນັບສະຫນູນງ່າຍ, ແລະອື່ນ.

ທີມງານທີ່ເປັນມິດດີຈະຮັບຟັງຈາກທ່ານ!