| Place of Origin: | Shandong, China |

| Brand Name: | jinzheng |

| Model Number: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grade1、Grade3、Grade4、Grade6、Grade7、Grade8、Grade9、Grade10、Grade11 |

| Certification: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS,, GS, ISO9001 |

| Minimum Order Quantity: | 1 ton |

| Price: | $650/ton |

| Packaging Details: | Exported Packaging Standard(In bundles Nylon bags, wooden cases or as required ) |

| Delivery Time: | 15-20days |

| Payment Terms: | FOB 30%T/T,70% before shipment |

| CIF 30% pre-payment and the balance to be paid before making shipment | |

| or Irrevocable 100% L/C at sight | |

| Supply Ability: | 2000 Ton/Tons per Month |

Quick Detail:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,seamless pipe,Seamless Carbon and Alloy Steel for Mechanical Tubing

A333 low temperature steel pipe is widely used in petrochemical, natural gas, chemical, electric power, heating and other fields. Its wide range of applications, flexible, In oil, natural gas transmission pipelines, petrochemical equipment, air conditioning system pipelines, coolers, steam generators, but also used in mechanical processing, pressure vessels, boiler manufacturing, building steel structure, large venues, exhibition centers, lifting machinery, shipbuilding, storage shelves, decoration, transportation facilities, airport construction, bridge support, mine support, three-dimensional garage, outdoor advertising, fitness equipment, Vehicle manufacturing and other industries

Chemical Requirements

| Element | Composition,% | ||||||||

| Grade 1A | Grade 3 | Grade 4 | Grade 6A | Grade 7 | Grade 8 | Grade 9 | Grade 10 | Grade 11 | |

| Carbon,max | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Manganese | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 max | 0.90 max | 0.40-1.06 | 1.15-1.50 | 0.60 max |

| Phosphorus, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Sulfur, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Silicon | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 min | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 max |

| Nickel | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 max | 35.0 -37.0 |

| Chromium | - | - | 0.44-1.01 | - | - | - | - | 0.15 max | 0.50 max |

| Copper | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 max | - |

| Aluminum | - | - | 0.04-0.30 | - | - | - | - | 0.06max | - |

| Vanadium, max | - | - | - | - | - | - | - | 0.12 | - |

| Columbium, max | - | - | - | - | - | - | - | 0.05 | - |

| Molybdenum,max | - | - | - | - | - | - | - | 0.05 | 0.50 max |

| Cobalt | - | - | - | - | - | - | - | - | 0.50 max |

Tensile Requlrements

| Grade 1 | Grade 3 | Grade 6 | Grade 7 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Tensile strength, minYield strength, min | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Longitudina | Transwerse | Longitudinal | Transwerse | Longitudinal | Transwerse | Longitudinal | Transwerse | |

| Elongation in 2 in. or 50mm, (or 40). min, %:Basic minimum elongation for walls 5/16 in. (8 mm) and over in thickness, strip tests.and for all small sizes tested in full sectionWhen standard round2-in. or 50-mm gage length or proportionally smaller size test specimen with the gage length equal to 4D (4times the diameter) is usedFor strip tests, a deduction for each 1/32 in. [0.8 mm] decrease in wall thickness below 5/16 in. (8 mm) from the basic minimum elongation of the following percentage |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| Grade 8 | Grade 9 | Grade 10 | Grade 11 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Tensile strength, minYield strength, min | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Longitudina | Transwerse | Longitudinal | Transwerse | Longitudinal | Transwerse | Longitudinal | ||

| Elongation in 2 in. or 50mm, (or 40). min, %:Basic minimum elongation for walls 5/16 in. (8 mm) and over in thickness, strip tests.and for all small sizes tested in full sectionWhen standard round2-in. or 50-mm gage length or proportionally smaller size test specimen with the gage length equal to 4D (4times the diameter) is usedFor strip tests, a deduction for each 1/32 in. [0.8 mm] decrease in wall thickness below 5/16 in. (8 mm) from the basic minimum elongation of the followingpercentage |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Description

1. Product brief introduction

Low-temperature seamless steel pipe is mainly used in petroleum, chemical, natural gas and coal as raw materials of ethylene, propylene, urea, synthetic ammonia, N-P-K composite fertilizer and pharmaceutical industry washing, purification, desulfurization and degrease production, as well as cryogenic equipment manufacturing, ultra-low temperature cold storage, transport ultra-low temperature liquefied gas pipeline and pipe components. The international low-temperature seamless steel pipe system is represented by ASTM A333/A333M-2011 (hereinafter referred to as the US standard), which is suitable for low temperature environment as low as -196℃. At present, the production and acceptance of low-temperature seamless steel pipe in the world mostly uses the US standard, and the domestic design also refers to the US standard. Among the nine grades of US standard cryogenic pipe, Gr.6 is widely used in the petrochemical industry and the fluid transport in low temperature and cold areas, and the annual demand in the US and European markets is more than 20,000 t.

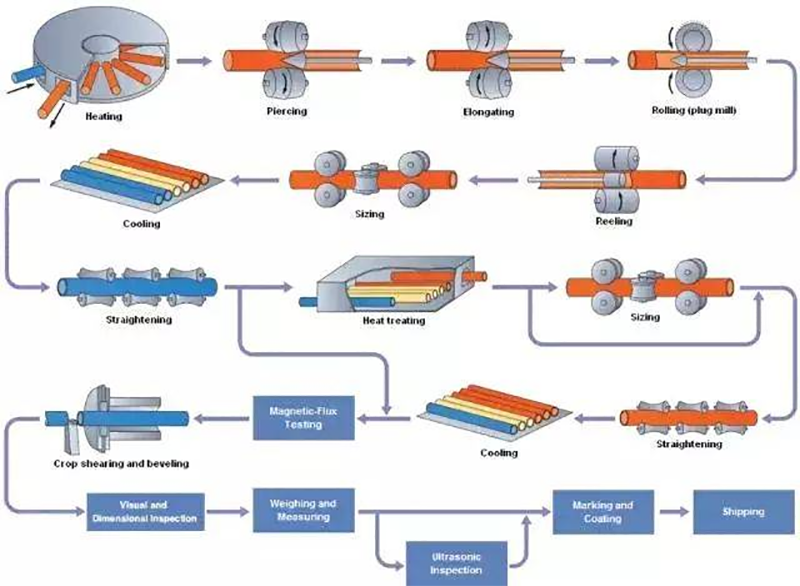

2. Manufacturing process

Manufacturing - Tubes are made by welding processes that are seamless or do not add filler metal. Level 4 shall be made of seamless process.

Heat treatment

All seamless and welded pipes shall be heat treated to control their microstructure by one of the following methods.

Uniformly heated to not less than 1500F (815℃) for positive heat treatment, and then air cooling or cooling in the cooling chamber of the controlled air oxygen furnace.

The steel pipe is normalized and reheated to an appropriate tempering temperature as determined by the steel mill. The pipe reheating well controls the hot processing, so that the operating temperature of the hot forming is controlled within the hot forming temperature range of 1550 to 1750F (845-945 ° C), and then it is cooled in the control gas oxygen furnace with an initial temperature of not less than 1550 (845 ° C). This method is only suitable for non-sewn tube processes.

It is treated and reheated to the appropriate tempering temperature as determined by the factory.

When specified in the order, the sample shall be cut from the thickness test block, which is taken from the steel pipe of the heat treated stone, and shall be stress-relieved. The test block shall be progressively heated to the specified temperature, moisturized at this temperature for the specified time, and then cooled to a temperature not higher than 600F (315 ° C). The test block of grade 8 steel pipe shall be air-cooled or water-cooled at a minimum cooling rate of 300F/ (165℃/h) to a temperature not higher than 600F (315℃).

3. The main brand or steel grade of the product

ASTM A333-Grade1、Grade4、Grade6、Grade7、Grade9、Grade10

ASTM A334-Grade1、Grade6、Grade7、Grade9

API 5CT80、L80-1、L803Cr、P110

4. Product implementation standards

GSTM 8333、 GSTM 8334、 API SPEC 5CT (9th)

5. Product feature

The company is resistant to low temperature and no vascular, the use of low sulfur and low phosphorus high purity steel and calcification treatment, can effectively reduce the low temperature brittleness of steel, improve the impact toughness of products. The company has 0 "-100C cooling tank, which can carry out low temperature impact test in batches to ensure the quality and stability of products.

6. Product use environment

A333 and A334 cryogenic tubes are used for -45-195C grade cryogenic lele vessel pipes and cryogenic heat exchanger pipes. They can also be used for fluid transport pipes in low temperature environments. The API5CT low-temperature resistant casing is mainly used for drilling Wells in extremely cold areas.The steel pipe can be used at extremely low temperatures, but also has high strength, corrosion resistance, good process ability and weld ability. These characteristics make the A333GR.6 low temperature steel pipe widely used in oil, natural gas, chemical and other industrial fields.

7. Product specification range

Outside diameter:16mm~323.9mm;Wall thickness:2.0mm~40.0mm

Applications:

Widely used in petrochemical, natural gas, chemical, electric power, heating and other fields. Its wide range of applications, flexible, In oil, natural gas transmission pipelines, petrochemical equipment, air conditioning system pipelines, coolers, steam generators, but also used in mechanical processing, pressure vessels, boiler manufacturing, building steel structure, large venues, exhibition centers, lifting machinery, shipbuilding, storage shelves, decoration, transportation facilities, airport construction, bridge support, mine support, three-dimensional garage, outdoor advertising, fitness equipment, Vehicle manufacturing and other industries3

Specifications:

Standards of seamless steel pipe

| API SPEC 5L | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Line Pipes | API 5L | Ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Casing | API 5CT | Ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubing | API 5CT | Ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Black and Hot-Dipped Zinc-Coated Seamless Steel Pipes | ASTM A53 | Ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Seamless Carbon Steel Pipes for High Temperature Service | ASTM A106 | Ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes | ASTM A179 | Ø10.3~426x WT1.0~36 | Low Carbon Steel |

| Seamless Carbon Steel Boiler Tubes for High Pressure | ASTM A192 | Ø10.3~426 x WT1.0~36 | Low Carbon Steel |

| Seamless Cold-Drawn Intermediate Alloy Steel Heat-Exchanger and Condenser Tubes | ASTM A199 | Ø10.3~426 x 1.0~36 | T5, T22 |

| Seamless Medium-Carbon Steel Boiler and Superheater Tubes | ASTM A210 | Ø10.3~426 x WT1.0~36 | A1, C |

| Seamless Ferritic & Austenitic Alloy Steel Boiler, Superheater & Heat-Exchanger Tubes | ASTM A213 | Ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Seamless Carbon and Alloy Steel for Mechanical Tubing | ASTM A333 | Ø1/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Seamless & Welded Carbon Steel Pipes and Alloy Steel Pipes for Low Temperature Use | ASTM A334 | Ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Seamless Cold-Drawn Carbon Steel Feedwater Heater Tubes | ASTM A556 | Ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Seamless Steel Tubes for Elevated Temperature | DIN 17175 | Ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Seamless Steel Tubes | DIN 1629 / DIN 2391 | Ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Seamless Steel Tubes | DIN 2440 | Ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Seamless Steel Pipes for Structural Purpose | DIN 2393 | Ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| Product Name | Executive Standard | Dimension (mm) | Steel Code / Steel Grade |

| Seamless Steel Tubes for Machine Structure | BS 970 | Ø10~762x WT1.0~120 | Carbon Steel |

| Seamless Steel Tubes for Boiler and Heat Exchangers | BS 3059 | Ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Competitive Advantage:

1. Light weight.

The parameter is 1/5 of the square steel, so it has better weight and light performance, lighter than the square steel, and its weight is only 1/5 of the square steel.

2. Corrosion and high temperature resistance.

It has good corrosion resistance and high temperature resistance, better than square steel, A333 corrosion resistance to acid, alkali, salt and atmospheric environment corrosion, high temperature resistance, good impact resistance and fatigue resistance, does not need regular maintenance, effective service life can reach more than 15 years.

3, no deformation and anti-static.

It has good antistatic properties, better than ordinary steel pipes, seamless pipes are highly elastic, reused in mechanical equipment, no memory, no deformation, and antistatic, seamless pipes have excellent mechanical properties, easy machining, etc.

Our friendly team would love to hear from you!