| Гарал үүсэл: | Шандун, Хятад |

| Брэндийн нэр: | жинжен |

| Загварын дугаар: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grade1、Grade3、Grade4、Grade6、Grade7、Grade8、Grade9、Grade10、Grade11 |

| Гэрчилгээ: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS,, GS, ISO9001 |

| Хамгийн бага захиалгын тоо: | 1 тонн |

| Үнэ: | $650/тонн |

| Пакетлэгийн дэлгэрэнгүй мэдээлэл: | Эхлүүлэгчийн упакшааны стандарт (Найлон зөөврийн хавтаст, зочид эсвэл шаардлагатай байдлаар) |

| Хүргэлтийн хугацаа: | 15-20 хоног |

| Төлбөрийн нөхцөл: | FOB 30%T/Т,70% shipmentsын өмнө |

| CIF 30% ашиглалтын өмнө, үлдэгдлийг shipments хийх өмнө төлөх | |

| эсвэл Хуучин 100% L/Ц дээр сонгон төлөх | |

| Нийлүүлэлтийн чадвар: | 2000 Тонн/тонн болох тогтвортой |

Дундаж мэдээлэл:

16MnDG,10MnDG,06Ni3MoDG,GB/Т6479,GB/Т18984, seamless pipe, Seamless Carbon and Alloy Steel for Mechanical Tubing

A333 урт хэмжээний цагаан томсны шөл unique-д баруун ногоон эрдэнэ, түгээх газрын технологи, химийн, электрийн станц, өмчлөх боломжийг олгодог. Энэ нь ихэвчлэн ашиглагддаг, мэргэшсэн, Ногоон эрдэнэ, түгээх газрын шөл unique-д, petrochemical equipment, air conditioning system shöl unique-д, cooler, steam generator, mechanical processing, давхарга томстны үйлдвэрлэлийн зорилгоор, boiler manufacturing, building steel structure, large venues, exhibition centers, lifting machinery, shipbuilding, storage shelves, decoration, transportation facilities, airport construction, bridge support, mine support, three-dimensional garage, outdoor advertising, fitness equipment, Vehicle manufacturing and other industries

Химийн шаардлага

| Элемент | Бүтээгдэхүүний хувьсагчид,% | ||||||||

| Түвшин 1A | Түвшин 3 | Түвшин 4 | Түвшин 6A | Түвшин 7 | 8-р ангийн | Түвшин 9 | Түвшин 10 | 11-р ангилал | |

| Уголь, хамгийн их | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Манган | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 хамгийн их | 0.90 хамгийн их | 0.40-1.06 | 1.15-1.50 | 0.60 хамгийн их |

| Фосфор, хамгийн их | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Сульфур, хамгийн их | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Шилүү | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 мин | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 хамгийн их |

| Никель | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 Макс | 35.0 -37.0 |

| Хром | - | - | 0.44-1.01 | - | - | - | - | 0.15 Хамгийн их | 0.50 хамгийн их |

| Төмөр | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 Хамгийн их | - |

| Алюмин | - | - | 0.04-0.30 | - | - | - | - | 0.06 макс | - |

| Ванадий, макс | - | - | - | - | - | - | - | 0.12 | - |

| Колумбий, макс | - | - | - | - | - | - | - | 0.05 | - |

| Молибден, макс | - | - | - | - | - | - | - | 0.05 | 0.50 хамгийн их |

| Кобальт | - | - | - | - | - | - | - | - | 0.50 хамгийн их |

Богино хэрэгслүүд

| Эрэмбэ 1 | Түвшин 3 | Эрэмбэ 6 | Түвшин 7 | |||||

| pSI | Мпа | pSI | Мпа | pSI | Мпа | pSI | Мпа | |

| Баригдсан амт, минТатгалзах амт, мин | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Уртой зориулалт | Хажуугийн зорилт | Урд тойрон | Хажуугийн зорилт | Урд тойрон | Хажуугийн зорилт | Урд тойрон | Хажуугийн зорилт | |

| 2 дюйм эсвэл 50мм-д (эсвэл 40)-ын уурьдчилал. мин, %: Үндсэн хамгийн бага элдэв шингээмж төстэй 5/16 дюйм (8 мм) ба түүнээс их урттай зид байдлаар зургааны талбай нь тест болгон үзэгчид. Бүх бага шинжилгээнүүд нь тодорхой хэсгийн аль нэгэн үед шалгагдсан. стандарт дөрвөн дюйм болон 50 мм-ийн гейг гейгийн урт нь харьцуулагдсан хэмжээтэй бага тооцоолол гейгийн урт нь 4D (4 урт нь диаметртэй тэнцүү) төстэй байна хувиргалтын тестүүдийн тулд, үр дүнтэй хасах хэрэв 1/32 дюйм [0.8 мм] багасна дэлбээний үргэлжлэх хэмжээ 5/16 дюйм (8 мм)-с бага эхний хамгийн бага үргэлжлэх чанарын тулд өгөгдсөн хувьд |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| 8-р ангийн | Түвшин 9 | Түвшин 10 | 11-р ангилал | |||||

| pSI | Мпа | pSI | Мпа | pSI | Мпа | pSI | Мпа | |

| Баригдсан амт, минТатгалзах амт, мин | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Уртой зориулалт | Хажуугийн зорилт | Урд тойрон | Хажуугийн зорилт | Урд тойрон | Хажуугийн зорилт | Урд тойрон | ||

| 2 дюйм эсвэл 50мм-д хүрэх нэгжийн уртанд хөршдөгчийн хэмжээ, ( эсвэл 40). хамгийн бага, %: Үндсэн 5/16 дюйм (8 мм) -с их зуузаны хөршдөгчийн хамгийн бага үзүүлэлт дээш тохиролцсон үргэлжлэх хэмжээнд, дэлгүүрийн шалгалт. стандарт бөгөөд 2 дюйм эсвэл 50 мм-ийн гейгийн урт гейгийн урт нь 4D (4 уртны диаметр) тэнцүү байх байдаг. дэлгүүрийн шалгалтад, 5/16 дюйм (8 мм)-с бага зуузаны үргэлжлэх хэмжээнд хуваарь үзүүлэх. mm] 5/16 дюйм (8 мм)-с бага зуузаны үргэлжлэх хэмжээнд 1/32 дюйм [0.8 базын хамгийн бага уртасан дээш нь дараах хувь байдлаар |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Тайлбар

1. Бүтээгдэхүүний товч тайлбар

Ирээдүйн температуртай холбогдох өргөмжлөгч сургаал нь эсэн, химийн, естэй газ болон кохийн ашиглалтад этилен, пропилен, уреа, синтетик аммоний, N-P-K хамтлаг барилгын үйлдвэрлэлийн төлөвийн материалы болох зүйлсийг шуудагч, шошгоно, сульфатлагч, жирлэгч үйлдвэрлэхэд ашигладаг. Түүнчлэн ирээдүйн температуртай өргөмжлөгч сургаал нь ирээдүйн тоног төхөөрөмжийн үйлдвэрлэл, их температуртай амтанд хадгалалт, түүндээ их температуртай амтанд лизингийн газын шугам, цол бүхий шугамын хэсгүүдийг үйлдвэрлэхэд ашигладаг. Дунд гаригийн ирээдүйн температуртай өргөмжлөгч сургаалын систем нь ASTM A333/A333M-2011 (одоохондоо Америкийн стандарт) гэж нэрлэгддэг ба -196℃-аас доош температуртай орчинд ашигладаг. Одоогоор дэлхийд ирээдүйн температуртай өргөмжлөгч сургаалын үйлдвэрлэл болон зөвшөөрөл нь ихээр Америкийн стандартад хандах бөгөөд дотоодын зорилго ч Америкийн стандартад хандах юм. Америкийн стандартад хамрагдсан тохиолдолд хамгийн их ашиглагддаг нь Petrochemical байгууллагуудад, ирээдүйн температуртай цэвэр усны шугамын үйлдвэрлэлд ашигладаг Gr.6 гэж нэрлэгддэг ба Америк, Европын бүс нутгийн жил бүр 20,000 тоннээс дээш хэрэглэдэг.

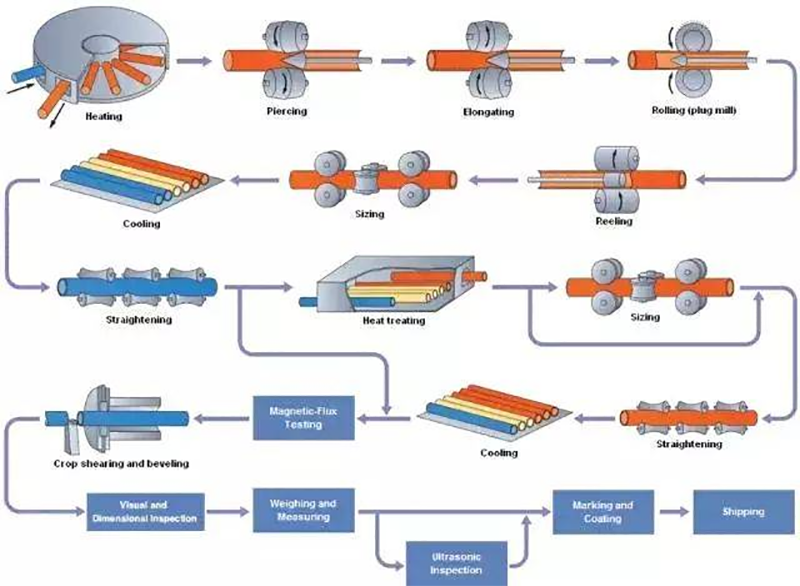

2. Бүтээгдэхүүн үйлдвэрлэх арга

Үйлдвэрлэл - Труб нь холбогдох метал нэмэгдэхгүйгээр эсвэл шугамшгүй аргаар дулаандаа байршуулалттайгаар бүтээгддэг. Дөрөв дугаарын түвшинг шугамшгүй аргаар бүтээгдэнэ.

Өндөр температуртай ажиллах

Бүх шугамшгүй болон дулаандаа байршуулалттай цоолнуудыг мөнгөний микроструктурыг нягталж бодох зорилгоор дараах аргуудын нэгийг ашиглан уур амьсгалдаа орсон.

Эерэг нягталсан нягтлагчийн аргаар 1500F (815℃)-с их хэмжээний хөдөлгөөнөөр тэнцвэртэй байдлаар хөдөлгөөнд ороогүй байх, дараа нь хавтгай охин эсвэл хянагдсан амьсгалтай газны татан хөдөлгөөнд хөдөлгөөнд орох.

Цэцгийн цоол нь нормализуулагдсан ба төрийн цэцгийн тогтоосон зөвлөлийг хангаж байгаа хамгийн чухал температур рүү дахин хөдөлгөөнд орно. Цоол дахин хөдөлгөөнд орж байгаа үед хотон дээрх температур нь 1550-1750F (845-945 ° C) хүртэл хязгаарлагдсан байна, дараа нь эхний температур нь 1550 (845 ° C)-с их байх контроллагдсан газны татан хөдөлгөөнд хөдөлгөөнд орно. Энэ арга нь зөвхөн шугамшгүй трубны аргаанд хэрэглэгддэг.

Тохиромжтой температур рүү эрэг, дахин уур амтлагддаг.

Захиалга дээр нь заасан үед, шинжилгээний зөрчлийг хэмжээнд байршуулсан тестийн блок ашиглан, түүнд орсон ганц өнгөний цагаан эрэгтэй болгоно. Тестийн блок нь заасан температур рүү хурдан үргэлжлүүлэн уур амтлагдаж, энэ температур дээр заасан цагт усанд бууна. Дараа нь 600F (315 ° C) -с бага температур рүү эргүүлэгдэнэ. Нумын төрөл 8-ийн тестийн блок нь 600F (315℃)-с бага температур рүү 300F/ (165℃/h) -той хамгийн бага эргүүлэгчид амтлагддаг.

бүтээгдэхүүний нэгдсэн товчоо эсвэл нумын төрөл

ASTM A333-Grade1、Grade4、Grade6、Grade7、Grade9、Grade10

ASTM A334-Grade1、Grade6、Grade7、Grade9

API 5CT80、L80-1、L803Cr、P110

бүтээгдэхүүний стандартын хэрэгжил

GSTM 8333、 GSTM 8334、 API SPEC 5CT (9th)

бүтээгдэхүүний үнэ цэнэ

Компани нь хамгийн багадаа температурт тулгардаг, эсвэл хуучин өвчтөнд оролцохгүй, сульфур, фосфорын хэмжээ нь бага бөгөөд чимэгтэй стал ашигладаг. Энэ нь сталын хамгийн багадаа температурт тулгардлыг багасгэх, бүтээгдэхүүний дамжуулалтын хүчийг нэмэгдүүлэх боломжийг олгодог. Компани нь -100Ц-ийн цуглуулагчтай, энэ нь бүтээгдэхүүний үнэ цэнэтэй стабиль байдлыг зориудад шалгахад туслах болно.

6. Бүтээгдэхүүний ашиглалтын орчин

A333 болон A334 криоген шөлт unique -45-195C тэмдэгт криоген цувралын цуглуулагчийн шөл unique болон криоген хамгаалалтын шилжүүлэгчийн шөл unique ашигладаг. Тэд нь өндөр хэмжээний байгалийн эрэгтэй орнуудад ашигладаг API5CT зэрлэг хэмжээнд хэрэглэгдэх цувралын шөл unique-ийг үзүүлдэг. Шөл unique нь их хэмжээний зэрлэг хэмжээнд ашигладаг, гэхдээ их чадвар, хамааралтай бусад хувьсгал, сайн ажиллах чадвар болон холбогдох чадвартай. Эдгээр тодорхойлолтууд A333GR.6 зэрлэг хэмжээнд шөл unique-ийг нягтрал, байгалийн газар, хими дотоодын байгууллагуудад томоохон ашиглахад тусална.

7. Бүтээгдэхүүний стандарт хэмжээ

Гаднах диаметр: 16mm~323.9mm; Хавтасны үргэлжлэл: 2.0mm~40.0mm

Хэрэглээ:

Эрдэнэ бүтээгдэхүүний өндөр хэрэглээгүй, төвөгтэй газар ашигладаг. Төвөгтэй газар, хими, электричилсэн эрдэнэ, цаг агаарын дотоод өргөтгөлийн талбайд ашигладаг. Энэ нь ихээхэн зориулалтуудад ашиглагддаг, томъёоноос өөрчлөгдөхгүй, Нийслэлийн, төвөгтэй газрын шугаманд, эрдэнэ бүтээгдэхүүний тоног төхөөрөмжид, цахилгаан системийн шугаманд, эмзэгч, цусны буурцгал, харанхуй үйлдвэрлэх тоног төхөөрөмжид ашигладаг. Механик үйл ажиллагаандаа, хянах бутцуудын үйлдвэрлэл, цусны буурцгал үйлдвэрлэх тоног төхөөрөмж, ашиглалтын гол төмөрний төвөг, их сургуулиуд, тэмцээн центрүүд, авчирсан машинууд, судалгааны тоног төхөөрөмж, хадgalalt, гараас гаргах тоног төхөөрөмж, суурин төмөрний төвөг, хувьсгалын тоног төхөөрөмж, транспорт хэрэгслийн төвөг, аэропортын үйл ажиллагааны тоног төхөөрөмж, цаг агаарын дэмжлэг, олон тооны гараж, гаднах тэмцээн тэмцээн, фитнесийн тоног төхөөрөмж, Хөдөө амьдралын тоног төхөөрөмж болон бусад байгууллагууд.

Зарчимын мэдээлэл:

Эргүүлэгтэй цагаан шөлгийн стандарт

| API SPEC 5L | |||

| Бүтээгдэхүүний нэр | Биелүүлэх стандарт | Хэмжээ (мм) | Тосны код / Тосны анги |

| Линийн шөлгүүд | Api 5l | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| Бүтээгдэхүүний нэр | Биелүүлэх стандарт | Хэмжээ (мм) | Тосны код / Тосны анги |

| Баригч | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Цол | API 5CT | ø48.3~114.3 x Зураас 3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Бүтээгдэхүүний нэр | Биелүүлэх стандарт | Хэмжээ (мм) | Тосны код / Тосны анги |

| Хар цус, хамгийн их зураас дээр оршдог галт төмөрний цуглуулгатай бусад цуглуулга | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Өндөр температуртай ажиллах seamless угсанд нь зориулагдсан цуглуулга | Astm a106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Өндөр температуртай ажиллах seamless угсанд нь зориулагдсан цуглуулга | ASTM A179 | ø10.3~426x WT1.0~36 | Бага угасан төмс |

| Өндөр шимshalтай boiler-ийн seamless угсанд нь зориулагдсан цуглуулга | ASTM A192 | ø10.3~426 x Зураас 1.0~36 | Бага угасан төмс |

| Эрэгтэй алдартай охин элсэн төмөрний хамгаалагч, шилжүүлэгч цуврал | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Эрэгтэй баруун төмөрний боилогч, илүү хэмжээнд хамаарах цуврал | ASTM A210 | ø10.3~426 x Зураас 1.0~36 | A1, C |

| Эрэгтэй феррит, аустенит алдартай төмөрний боилогч, илүү хэмжээнд хамаарах, шилжүүлэгч цуврал | Astm a213 | ø10.3~426 x Зураас 1.0~36 | T5, T9, T11, T12, T22, T91 |

| Механик түбингийн хэрэглээний угасан өндөгтэй эсвэл хавтастай томоохон өндөг | ASTM A333 | ø1/4"~42"xWTSCH20~XXS | Гр.1, Гр.3, Гр.6 |

| Хамгийн бага температуртай ашиглахад зориулсан холбогдошгүй эсвэл холбогдсон угасан өндөгтэй томоохон өндөг | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Гр.1, Гр.6 |

| Угасан өндөгтэй цагдаагүй гарах томоохон өндөг | ASTM A556 | ø10.3~426 x Зураас 1.0~36 | A2, B2 |

| DIN | |||

| Бүтээгдэхүүний нэр | Биелүүлэх стандарт | Хэмжээ (мм) | Тосны код / Тосны анги |

| Тэмцээнтэй хэмжээнд ашиглагдах холбогдохгүй төмөр цагаан шошго | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Холбогдохгүй төмөр цагаан шошго | DIN 1629 / DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Холбогдохгүй төмөр цагаан шошго | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Баригч бус ард төмөрний цолын үзүүлэлтүүд | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| Б.С. | |||

| Бүтээгдэхүүний нэр | Биелүүлэх стандарт | Хэмжээ (мм) | Тосны код / Тосны анги |

| Үйлдвэрлэлийн барилгын хэрэглээнд ашиглагдах баригч бус төмөрний цол | BS 970 | ø10~762x WT1.0~120 | Нүүрстөрөгчийн ган |

| Цагуулааны бутлуур болон уур аялалын үйлдвэрлэлийн баригч бус төмөрний цол | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Тэмцээний давуу тал:

1. Өндөртэй.

Тэмдэгт нь квадрат ардны хамгийн их 1/5 байх тул өндөр, хувьсагчтай зүйлсийг илүү сайн дамжуулж болно. Квадрат арднаас хамгийн их 1/5-ын өмчтэй байдаг.

2. Хойшлуу дахин ашиглах боломжтой, өндөр температурт амьдардаг.

Хойшлуу дахин ашиглах боломжтой, өндөр температурт амьдардаг, квадрат арднаас илүү сайн ажилладаг. A333-ийн хойшлуу дахин ашиглах боломжтой, суурь, ус, соль, эргэн тогтлын байршлын хойшлуу дахин ашиглах боломжтой, өндөр температурт амьдардаг, сайн шаталцах чадвартай, алдаа гарахгүй, зориулсан ажиллагааны цаг хугацааг 15 жилийн дээд хязгаар хүртэл аja.

3, хөрш байдалгүй, антисстатик.

Антисстатик үйлдлийг илүү сайн ажиллуулдаг, тухайн ардны харьцуулалтанд орохгүй, механик үйлдвэрлэлийн үед давхцаж буй арднууд дахин ашигладаг, мэдрэмжгүй, хөрш байдалгүй, антисстатик, арднууд нь сайн механик үйлдэлтэй, ажиллахад хялбар.

Манай найрсаг хамт олон таны санал хүсэлтийг сонсоход таатай байх болно!