| Tempat Asal: | Shandong, China |

| Nama Brand: | jinzheng |

| Nombor Model: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grade1、Grade3、Grade4、Grade6、Grade7、Grade8、Grade9、Grade10、Grade11 |

| Penyeliaan: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| Kuantiti Pesanan Minimum: | 1 tan |

| Harga: | $650/ton |

| Butir-butir Pemakanan: | Piawai Pemakanan Eksport (Dalam genggaman beg nilon, kotak kayu atau mengikut permintaan) |

| Masa Penghantaran: | 15-20hari |

| Syarat Pembayaran: | FOB 30%T/T, 70% sebelum penghantaran |

| CIF 30% pembayaran awal dan baki dibayar sebelum membuat penghantaran | |

| atau L/C 100% Irrevocable pada pandangan | |

| Kemampuan Bekalan: | 2000 Ton/Tons sebulan |

Perincian ringkas:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,pipca tanpa jahitan,Pipca Karbon dan Keluli Kekaluan untuk Tabung Mekanikal

Pipca keluli suhu rendah A333 digunakan secara meluas dalam petrokimia, gas asli, kimia, kuasa elektrik, pemanasan dan bidang lain. Ia mempunyai julat aplikasi yang luas, fleksibel, dalam paip penghantaran minyak dan gas asli, peralatan petrokimia, sistem penyejukan, penyejuk, penjana uap, juga digunakan dalam pemprosesan mekanikal, bekas tekanan, pembuatan ketuhar, struktur keluli binaan, tempat besar, pusat pameran, kraf angkat, pembinaan kapal, rak storan, dekorasi, kemudahan pengangkutan, pembinaan lapangan terbang, penyokong jambatan, sokongan tambang, garaj tiga dimensi, iklan luaran, peralatan kesihatan, pembuatan kenderaan dan industri lain.

Kebutuhan Kimia

| Unsur | Komposisi,% | ||||||||

| Gred 1A | Gred 3 | Gred 4 | Gred 6A | Gred 7 | Gred 8 | Gred 9 | Gred 10 | Gred 11 | |

| Karbon,maks | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Mangan | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 maks | 0.90 maks | 0.40-1.06 | 1.15-1.50 | 0.60 maks |

| Fosforus, maks | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Sulfur, maks | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Silikon | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 minit | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 maks |

| Nikel | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 maks | 35.0 -37.0 |

| Kromium | - | - | 0.44-1.01 | - | - | - | - | 0.15 max | 0.50 maks |

| Tembaga | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 max | - |

| Aluminium | - | - | 0.04-0.30 | - | - | - | - | 0.06maks | - |

| Vanadium, maks | - | - | - | - | - | - | - | 0.12 | - |

| Columbium, maks | - | - | - | - | - | - | - | 0.05 | - |

| Molybdenum, maks | - | - | - | - | - | - | - | 0.05 | 0.50 maks |

| Kobalt | - | - | - | - | - | - | - | - | 0.50 maks |

Kebutuhan Tarikan

| Kelas 1 | Gred 3 | Gred 6 | Gred 7 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Kekuatan tarik, minKekuatan leleh, min | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Longitudina | Transwerse | Lonjitudinal | Transwerse | Lonjitudinal | Transwerse | Lonjitudinal | Transwerse | |

| Pemanjangan dalam 2 in. atau 50mm, (atau 40). min, %: Pemanjangan asas minimum untuk dinding 5/16 in. (8 mm) dan lebih tebal dalam ketebalan, ujian jalur. dan untuk semua yang kecil saiz diuji dalam segmen penuhApabila piawai bulat 2-inch. atau panjang jangka 50-mm saiz yang lebih kecil secara proporsional contoh ujian dengan panjang jangka sama dengan 4D (4 kali diameter) adalah digunakanUntuk ujian jalur, pengurangan untuk setiap 1/32 inch [0.8 mm] penurunan dalam ketebalan dinding di bawah 5/16 inch (8 mm) dari elongasi minimum asas daripada peratusan berikut |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| Gred 8 | Gred 9 | Gred 10 | Gred 11 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Kekuatan tarik, minKekuatan leleh, min | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Longitudina | Transwerse | Lonjitudinal | Transwerse | Lonjitudinal | Transwerse | Lonjitudinal | ||

| Pemanjangan dalam 2 in. atau 50mm, (atau 40). min, %: Asas pemanjangan minimum untuk dinding 5/16 in. (8 mm) dan lebih tebal dalam ketebalan, ujian jalur dan untuk semua saiz kecil yang diuji penuh dalam seksyen. Apabila piawai bulat 2-in. atau spesimen ujian 50-mm janggut panjang atau saiz yang lebih kecil secara proporsional dengan janggut bersamaan dengan 4D (4 kali diameter) adalah digunakan Untuk ujian jalur, pengurangan untuk setiap 1/32 in. [0.8 mm] penurunan dalam ketebalan dinding di bawah 5/16 in. (8 mm) dari pemanjangan minimum asas peratusan berikut |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Penerangan

1. Pendahuluan ringkas produk

Paip keluli tanpa sambungan suhu rendah terutamanya digunakan dalam minyak, kimia, gas asli dan batubara sebagai bahan mentah etilena, propilena, urea, amonia sintetik, baja N-P-K komposit dan industri farmasi mencuci, pemurnian, pengeluaran sulfur dan lemak, serta pembuatan peralatan suhu rendah, storan suhu sangat rendah, pengangkutan paip gas cecair suhu sangat rendah dan komponen paip. Sistem paip keluli tanpa sambungan suhu rendah antarabangsa diwakili oleh ASTM A333/A333M-2011 (disebutkan sebagai piawai AS), yang sesuai untuk persekitaran suhu rendah sehingga -196℃. Pada masa kini, pengeluaran dan penerimaan paip keluli tanpa sambungan suhu rendah di seluruh dunia banyak menggunakan piawai AS, dan reka bentuk dalam negara juga merujuk kepada piawai AS. Diantara sembilan gred paip cryogenik piawai AS, Gr.6 meluas digunakan dalam industri petrokimia dan pengangkutan bendalir dalam kawasan suhu rendah dan sejuk, dan permintaan tahunan di pasaran AS dan Eropah adalah lebih daripada 20,000 t.

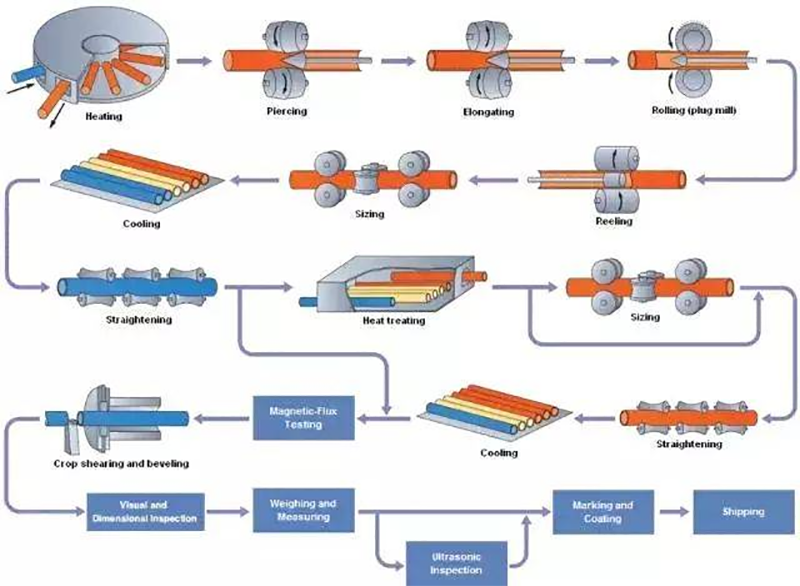

2. Proses pembuatan

Pengeluaran - Tiub dibuat melalui proses penyuduan yang tidak bersepadu atau tidak menambah logam pengisi. aras 4 harus dibuat daripada proses tanpa sambungan.

Rawatan haba

Semua paip tanpa sambungan dan disambungkan mesti dikenakan rawatan haba untuk mengawal mikrostruktur mereka oleh salah satu kaedah berikut.

Dipanaskan secara seragam kepada sekurang-kurangnya 1500F (815℃) untuk rawatan haba positif, kemudian didinginkan dengan udara atau didinginkan dalam bilik penyejukan ketuh angin oksigen yang dikawal.

Paip keluli dinormalkan dan dipanaskan semula kepada suhu penapisan yang sesuai seperti yang ditentukan oleh kilang keluli. Penyaman semula paip mengawal pemprosesan panas dengan baik, supaya suhu operasi pembentukan panas dikawal di dalam julat suhu pembentukan panas 1550 hingga 1750F (845-945 ° C), dan kemudian didinginkan dalam ketuh angin oksigen yang dikawal dengan suhu permulaan sekurang-kurangnya 1550 (845 ° C). Kaedah ini hanya sesuai untuk proses paip tanpa jahitan.

Ia diperlakukan dan dipanaskan semula kepada suhu penyeragam yang sesuai seperti yang ditentukan oleh kilang.

Apabila dinyatakan dalam pesanan, contoh akan dipotong daripada blok ujian ketebalan, yang diambil daripada paip keluli batu yang telah dikenakan rawatan panas, dan harus dilepaskan tekanannya. Blok ujian akan dipanaskan secara bertahap kepada suhu yang ditentukan, diberi kelembapan pada suhu ini untuk masa yang ditentukan, dan kemudian didinginkan kepada suhu tidak lebih tinggi daripada 600F (315 ° C). Blok ujian paip keluli gred 8 harus didinginkan dengan udara atau air pada kadar penyejukan minimum 300F / (165℃ / jam) kepada suhu tidak lebih tinggi daripada 600F (315℃).

3. Jantina utama atau gred keluli produk

ASTM A333-Grade1、Grade4、Grade6、Grade7、Grade9、Grade10

ASTM A334-Grade1、Grade6、Grade7、Grade9

API 5CT80、L80-1、L803Cr、P110

4. Piawaian pelaksanaan produk

GSTM 8333、 GSTM 8334、 API SPEC 5CT (9th)

5. Ciri-ciri produk

Kompani itu tahan terhadap suhu rendah dan tidak berpipa, penggunaan keluli kekalkan sulfur rendah dan fosfor rendah serta rawatan penakalan boleh mengurangkan kecederaan suhu rendah pada keluli, meningkatkan keteguhan impak produk. Kompani mempunyai tangki pendinginan 0 "-100C, yang boleh menjalankan ujian impak suhu rendah secara berpandukan untuk memastikan kualiti dan kestabilan produk.

6. Lingkungan penggunaan produk

Paip cryogenik A333 dan A334 digunakan untuk paip kapal lele kelas -45 hingga -195C dan paip penukar haba cryogenik. Ia juga boleh digunakan sebagai paip pengangkutan bendalir dalam persekitaran suhu rendah. Paip pelindung API5CT yang tahan suhu rendah terutamanya digunakan untuk menggali sum dalam kawasan yang sangat sejuk. Paip keluli boleh digunakan pada suhu sangat rendah, tetapi juga mempunyai kekuatan tinggi, ketahanan terhadap kerosakan, keupayaan proses yang baik dan kebolehan penyambungan. Ciri-ciri ini membuat paip keluli suhu rendah A333GR.6 digunakan secara meluas dalam bidang perindustrian seperti minyak, gas alam, kimia dan lain-lain.

7. Julat spesifikasi produk

Diameter luaran: 16mm~323.9mm; Ketebalan dinding: 2.0mm~40.0mm

Aplikasi:

Largely digunakan dalam petrokimia, gas asli, kimia, elektrik, pemanasan dan bidang lain. Julat aplikasi yang luas, fleksibel, Dalam paip penghantaran minyak dan gas asli, peralatan petrokimia, paip sistem penyejuk udara, penyejuk, penjana uap, juga digunakan dalam pemprosesan mesin, bekas tekanan, pembuatan boiler, struktur keluli binaan, tempat besar, pusat pameran, kawalan mesin, pembinaan kapal, rak storan, dekorasi, kemudahan pengangkutan, pembinaan lapangan terbang, penyokong jambatan, penyokong lombong, garaj tiga dimensi, iklan luar, peralatan fitness, Pembuatan kenderaan dan industri lain3

Spesifikasi:

Piawai paip keluli tanpa sambungan

| API SPEC 5L | |||

| Nama Produk | Piawaian Eksekutif | Dimensi (mm) | Kod Keluli / Gred Keluli |

| Paip Garis | Api 5l | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| Nama Produk | Piawaian Eksekutif | Dimensi (mm) | Kod Keluli / Gred Keluli |

| Casing | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubing | API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Nama Produk | Piawaian Eksekutif | Dimensi (mm) | Kod Keluli / Gred Keluli |

| Paip Keluli Tanpa Sambungan Berwarna Hitam dan Dilapisi Zink Hot-Dipped | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Paip Keluli Karbon Tanpa Sambungan untuk Perkhidmatan Suhu Tinggi | Astm a106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Paip Pengurangan Panas dan Tabung Penyahangin Keluli Karbon Rendah Tanpa Sambungan Ditarik Dingin | ASTM A179 | ø10.3~426x WT1.0~36 | Keluli karbon rendah |

| Paip Ketel Keluli Karbon Tanpa Sambungan untuk Tekanan Tinggi | ASTM A192 | ø10.3~426 x WT1.0~36 | Keluli karbon rendah |

| Tiub Penukar Haba dan Penyuling Selanggang Keluli Perantaraan Ditarik Dingin Tanpa Sambungan | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Tiub Ketuh Karbon Tengah untuk Ketel dan Superheater | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Tiub Ketuh Keluli Feritik & Austenitik Perpaduan untuk Ketel, Superheater & Penukar Haba | Astm a213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Karbon Tanpa Sambungan dan Keluli Baja untuk Paip Mekanikal | ASTM A333 | ø1/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Paip Karbon Tanpa Sambungan & Bersepadu untuk Penggunaan Suhu Rendah | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Paip Pemanas Air Umpan Keluli Karbon Ditarik Dingin Tanpa Sambungan | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| Bersuara | |||

| Nama Produk | Piawaian Eksekutif | Dimensi (mm) | Kod Keluli / Gred Keluli |

| Tiub Keluli Tanpa Sambungan untuk Suhu Tertinggi | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Tiub Keluli Tanpa Sambungan | DIN 1629 \/ DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Tiub Keluli Tanpa Sambungan | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Paip Keluli Tanpa Sambungan untuk Kegunaan Struktur | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| Nama Produk | Piawaian Eksekutif | Dimensi (mm) | Kod Keluli / Gred Keluli |

| Tiub Keluli Tanpa Sambungan untuk Struktur Mesin | BS 970 | ø10~762x WT1.0~120 | Keluli Karbon |

| Tiub Keluli Tanpa Sambungan untuk Ketuhar dan Penukar Haba | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Kelebihan Berbanding Pasukan:

1. Berat ringan.

Parameter ini adalah 1/5 daripada keluli segi empat, jadi ia mempunyai prestasi berat dan ringan yang lebih baik, lebih ringan daripada keluli segi empat, dan beratnya hanya 1/5 daripada keluli segi empat.

2. Tahan kerosakan dan suhu tinggi.

Ia mempunyai ketahanan kerosakan yang baik dan tahan suhu tinggi, lebih baik daripada keluli segi empat, A333 tahan kepada kerosakan asid, alkali, garam dan persekitaran atmosfera, tahan suhu tinggi, ketahanan terhadap impak dan keletihan yang baik, tidak memerlukan penyelenggaraan secara berkala, tempoh perkhidmatan yang efektif boleh mencapai lebih dari 15 tahun.

3, tiada deformasi dan anti-statik.

Ia mempunyai sifat anti-statik yang baik, lebih baik daripada paip keluli biasa, paip tanpa selembaran mempunyai elastisiti yang tinggi, boleh digunakan semula dalam peralatan mekanikal, tiada ingatan, tiada deformasi, dan anti-statik, paip tanpa selembaran mempunyai sifat mekanikal yang cemerlang, mudah diproses, dll.

Pasukan ramah kami ingin mendengar dari anda!