| Tempat Asal: | Shandong, China |

| Nama Brand: | $560-600/TON |

| Nombor Model: | A106/A53GRB API5L/Q195,Q235,Q275,Q355,Q345,SAE1010/1020,1045,dll |

| Penyeliaan: | API, CE, Bsi, RoHS, SNI, BIS, tisi, KS, JIS, GS, ISO9001 |

| Kuantiti Pesanan Minimum: | 1tan |

| Harga: | $560/TON |

| Butir-butir Pemakanan: | Piawaian Pemakanan Eksport (Dalam gandingan, beg-beg nilon, kotak kayu atau mengikut permintaan) |

| Masa Penghantaran: | 3-7hari |

| Syarat Pembayaran: | FOB 30%T/T, 70% sebelum penghantaran |

| CIF 30% pembayaran awal dan baki dibayar sebelum membuat penghantaran | |

| atau L/C 100% Irrevocable pada pandangan | |

| Kemampuan Bekalan: | 10000 Ton/Tons sebulan |

Perihalan:

Paip keluli berlumut dibahagikan kepada paip keluli berlumut panas dan paip keluli berlumut sejuk

Paip galvanis hot dip

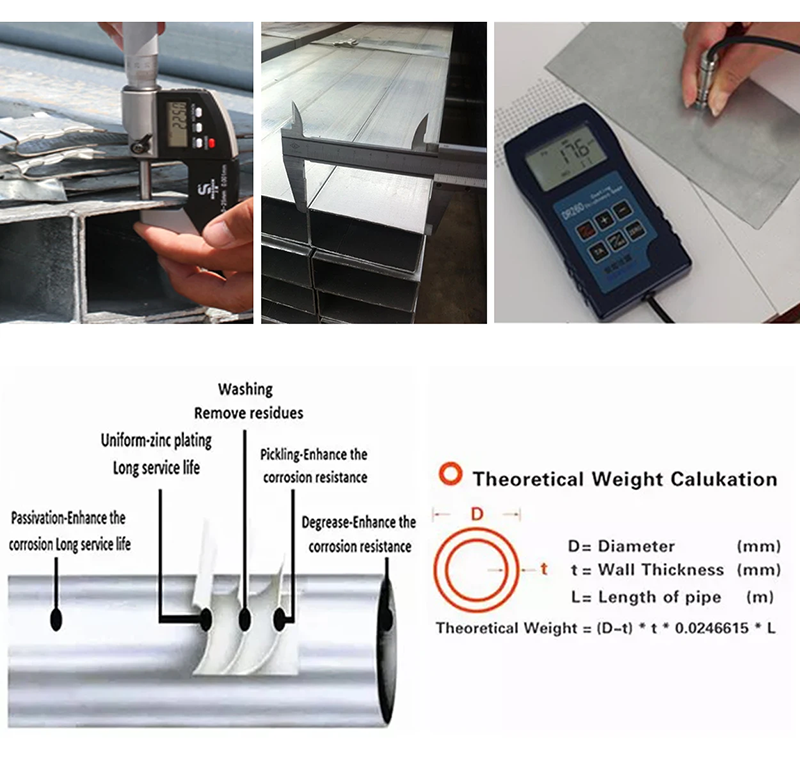

Logam cecair itu bertindak balas dengan matriks keluli untuk menghasilkan lapisan alloy, dengan itu menyatukan substrat dan lapisan plating. Galvanizing celup panas adalah untuk membasuh paip keluli terlebih dahulu, untuk mengeluarkan oksida keluli di atas permukaan paip keluli, selepas basuhan, ia dicuci oleh larutan air klorida amonium atau klorida zink atau larutan air campuran klorida amonium dan klorida zink, dan kemudian diberi. Tangki plating celup panas. Galvanizing celup panas mempunyai kelebihan pelapisan seragam, daya ikat kuat dan jangka hayat panjang. Kebanyakan proses di utara menggunakan jalur berlumut untuk melilitkan timah secara langsung

Paip galvanis dingin

Galvanisasi dingin adalah elektrogalvanisasi. Kuantiti galvanis sangat kecil, hanya 10-50g/m2, dan ketahanan karatnya jauh lebih buruk daripada paip galvanis hot-dip. Pengeluar paip galvanis biasa, untuk memastikan kualiti, kebanyakan tidak menggunakan elektrogalvanis (pelapisan sejuk). Hanya syarikat kecil dengan peralatan kecil dan peralatan lama yang menggunakan keluli elektrogalvanis, tentulah harga mereka agak lebih murah. Dalam rumah baru dibina, penggunaan paip keluli galvanis sejuk sebagai paip air dilarang.

Perbezaan antara galvanis hot-dip dan galvanis sejuk

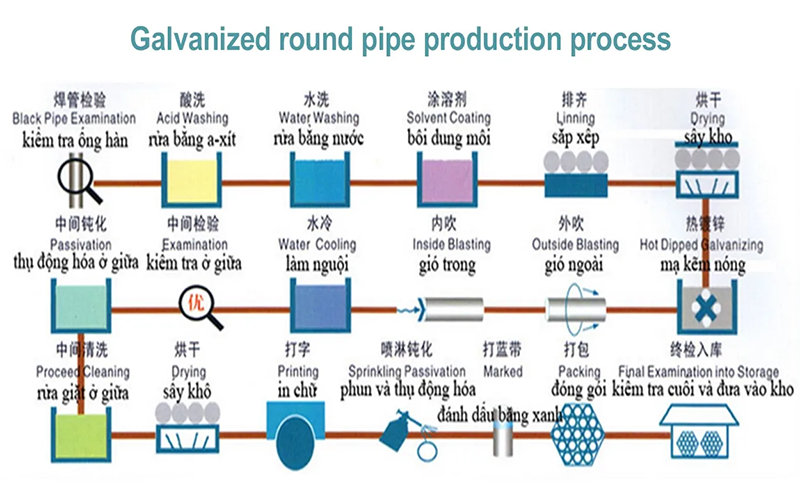

Proses galvanis hot-dip:

Benda kerja penyucian lemak → mencuci → asidifikasi → mencuci → mengeringkan celup peleburan pra-pemanasan hot dip galvanized → menyejukkan → penyempurnaan → membilas → mengeringkan → ujian pasif

Proses galvanis sejuk:

Pembersihan kimia → mencuci → elektrolisis air panas air panas → mencuci → mencuci → galvanis besi korosif kuat → mencuci → mencuci → ringan → → mencuci → pengeringan pasivasi

Kelebihan paip galvanis adalah seperti berikut:

Pertama, permukaan paip galvanis selepas digalvanis dengan celupan panas boleh dilindungi, dan di dalam rongga paip atau sudut mana-mana lapisan lain sukar untuk memasuki, tetapi zinc boleh dengan mudah menutupi keseluruhan, membuatkan keseluruhan paip galvanis boleh dilindungi.

Kedua, selepas paip diberi galvanis, ketahanan terhadap impak dan sifat anti-keluruhannya sangat baik, kerana nilai keras lapisan seng lebih besar daripada kerasnya keluli, oleh itu ketahanan terhadap impak dan keluruhannya selepas pencelupan panas adalah cukup baik. Selain itu, kelebihan terbesar galvanis adalah bahawa lapisan seng di sudut akan menjadi lebih tebal dengan ketangkasan dan ketahanan keluruh yang baik, manakala pelapis lain sering kali menjadi paling nipis dan sukar dibina di sudut ini, maka ia rentan kepada kerosakan.

Spesifikasi:

| l Penerangan | l Paip Bersepadu Dengan Galvanis | |

| l Gred Keluli | l Astm a53 Gr.B / ASTM A106 | |

| l Piawai | l ASTM A106/A106M;ASTM A53/A53M;API 5L;GB/T 8163-2008;GB/T 8162-2008;BS1387, BS1139,EN39, EN1139, ASTM A53, JIS G3444 | |

| l Bahan | l A106 Grade A,A106 Grade B,A106 Grade C,A53 Grade A,A53 Grade B,API 5L Grade B,10#,20#,45# | |

| l Permukaan | l Penyelaman panas; Elektro penyelaman; Kaedah yang diminta oleh pelanggan | |

| l Jenis | l 1. Dicat sebelumnya (zinc: 60-120G/M2) l 2. Diselam panas dengan zinc (zinc: 120-500G/M2) l 3. Diselam sejuk dengan zinc (zinc: 10-50G/M2) | |

| saiz L | l Ketebalan dinding | l 1-22mm |

| Diameter Luar | 21.3mm-610mm | |

| l Masa penghantaran | l Penghantaran pantas atau mengikut kuantiti pesanan. | |

| l Pakej | l Pakej eksport piawai yang sesuai untuk pengangkutan laut, atau mengikut permintaan. | |

| l Permohonan | l Menghantar bendalir; penyokongan struktur; HVAC; industri minyak dan gas; peralatan industri | |

| l Hubungi | l Jika anda ada sebarang soalan, sila rasa percuma untuk menghubungi saya. | |

| l Saiz bekas | l 20ft GP:5898mm(Panjang)x2352mm(Lebar)x2393mm(Tinggi) 24-26CBMl l 40ft GP:12032mm(Panjang)x2352mm(Lebar)x2393mm(Tinggi) 54CBMl l 40ft HC:12032mm(Panjang)x2352mm(Lebar)x2698mm(Tinggi) 68CBM |

|

Perincian ringkas:

1.gi paip, Paip Bulat Keluli Galvanised Dalam Mandi Panas, Paip Keluli Galvanised Tube,welded gi steel pipe,gi steel tube

2.Paip keluli bulat galvanis dalam mandi panas (HDG), digunakan secara meluas dalam pelbagai jenis industri dan kawasan pembinaan di seluruh dunia.

Paip galvanis dingin adalah galvanis elektrik, kuantiti galvanis sangat kecil, hanya 10-50g/m2, ketahanan terhadap karatnya jauh berbeza dengan paip galvanis panas.

Ia boleh digunakan dalam pembinaan, mesin-mesin, tambang batu bara, industri kimia, elektrik, kenderaan keretapi, perindustrian automotif, lebuh raya, jambatan, bekas, kemudahan sukan, mesin pertanian, mesin minyak, mesin penyiasatan dan industri pengeluaran lain-lain.

| Ciri Kimia % | |||||||||

| Gred A | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Gred B | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.3 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Gred C | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Ciri-ciri Mekanikal | |||

| Gred A | Gred B | Gred C | |

| Kekuatan Tarik | 330 | 415 | 485 |

| Kekuatan Hasil | 205 | 240 | 275 |

Penerangan:

Paip las berlapis galvanium merujuk kepada jenis paip keluli yang telah dilapisi dengan lapisan zink melalui proses yang dipanggil galvanization.

Proses galvanization melibatkan pencelupan paip keluli ke dalam bak zink cecair, yang membentuk lapisan pelindung pada permukaan paip.

Tujuan paip las berlapis galvanium adalah untuk memberi ketahanan terhadap kerosakan dan memperpanjang umur paip. Lapisan zink bertindak sebagai halangan di antara keluli dan persekitaran sekeliling, melindungi paip daripada karat dan bentuk kerosakan lain.

Ini menjadikan paip las berlapis galvanium sesuai untuk pelbagai aplikasi, terutamanya dalam industri di mana paparan kepada kelembapan atau bahan kerosakkan adalah biasa.

Beberapa kelebihan utama paip las berlapis galvanis termasuk:

1. Perlawanan terhadap kerosakan: Lapisan seng memberikan perlawanan kerosakan yang cemerlang, menjadikan paip galvanis sesuai untuk aplikasi luar dan bawah tanah.

2. Kekuatan: Gabungan keluli dan lapisan seng meningkatkan kekuatan dan keawetan paip, membolehkannya

menahan keadaan keras dan penggunaan berat.

3. Kecekapan kos: Paip las berlapis galvanis secara amnya lebih murah berbanding alternatif lain yang tahan kerosakan, menjadikannya pilihan yang kos-cekap untuk pelbagai projek.

4. Pemasangan mudah: Paip las berlapis galvanis relatif mudah dipasang kerana saiz standard dan kesesuaian mereka

dengan penyambung dan pengelek yang biasa digunakan.

5. Keluwesan: Paip las berlapis galvanis tersedia dalam pelbagai saiz dan ketebalan, menjadikannya sesuai untuk julat aplikasi yang luas, termasuk plombing, pembinaan, pertanian, dan projek industri.

Perlu diingat bahawa paip las galvanis mempunyai kehadiran. Dengan masa, lapisan seng mungkin akan rosak atau terkelupas,

terutamanya dalam persekitaran yang sangat kerosakkan. Oleh itu, pemeriksaan dan pemeliharaan secara berkala adalah perlu untuk memastikan perlindungan paip terus berjaya.

Selain itu, apabila bekerja dengan paip las galvanis, penting untuk mengambil langkah keselamatan yang betul, seperti menggunakan

peralatan pelindung peribadi yang sesuai dan memastikan ventilasi yang baik, kerana proses galvanis boleh melepaskan gas yang mungkin berbahaya jika diserap.

Aplikasi:

binaan, mesin, tambang batu bara, industri kimia, kuasa elektrik, kenderaan rel, industri automotif, lebuh raya, jambatan, bekas, kemudahan sukan, mesin pertanian, mesin petroleum, mesin penyiasatan dan industri pembuatan lain-lain.

Spesifikasi:

| Paip Keluli Bundar Galvanis | |||||||||

| Piawai:API 5L,API 5CT,ASTM A53,ASTM A500,GB9711.1 Kegunaan:Untuk digunakan dalam membawa gas, air, dan minyak untuk industri minyak dan gas asli dan digunakan untuk tujuan paip keluli struktur. Gred Paip Keluli Utama: GR.A, GR.B, GR.C, Q195, Q235B, Q345B dan sebagainya. |

|||||||||

| Inci | OD (mm) | Ketebalan Dinding Piawai | |||||||

| SCH 10WT (mm) | SCH 20WT (mm) | SCH 40WT (mm) | SCH 60WT (mm) | SCH 80WT (mm) | SCH 100WT (mm) | SCH 160WT (mm) | XXS (mm) | ||

| 1/4” | 13.7 | 2.24 | 3.02 | ||||||

| 3/8” | 17.1 | 2.31 | 3.2 | ||||||

| 1/2” | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.5 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.7 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.7 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

| 30" | 762 | 7.92 | 12.7 | ||||||

| 32" | 813 | 7.92 | 12.7 | 17.48 | |||||

| 34" | 863 | 7.92 | 12.7 | 17.48 | |||||

| 36" | 914 | 7.92 | 12.7 | 19.05 | |||||

| 38" | 965 | ||||||||

| 40" | 1016 | ||||||||

| 42" | 1066 | ||||||||

| 44" | 1117 | ||||||||

| 46" | 1168 | ||||||||

| 48" | 1219 | ||||||||

Kelebihan Berbanding Pasukan:

Kami mempunyai kelebihan harga yang kompetitif dan penghantaran tepat masa dalam bekalan paip keluli tanpa jahitan, tidak hanya untuk pelanggan berjumlah besar, tetapi juga menerima pesanan pelanggan untuk reka bentuk peribadi contoh, spesifikasi dan keperluan pakej.

Pasukan ramah kami ingin mendengar dari anda!