| Post ta' Origine: | Shandong, China |

| Ism Brand: | jinzheng |

| Numru Model: | 16MnDG, 10MnDG, 09DG, 09Mn2VDG, 06Ni3MoDG, ASTM A333-Grade1, Grade3, Grade4, Grade6, Grade7, Grade8, Grade9, Grade10, Grade11 |

| Certifikat: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| Kwantità minima għall-ordni: | 1 Ton |

| Prezz: | $650/ton |

| Dettagli tal-Pakkagin: | Standard ta' Pakkjiġġ tal-Eksport (Fittex Nylon, saqsiet tal-ħolm jew kif jirrequċi) |

| Tajp tal-konsegna: | 15-20 iġbor |

| Termini tal-pagament: | FOB 30% T/T, 70% qabel is-Sipping |

| CIF 30% pre-pagament u l-bilanċ li jkun jagħmel pagament qabel jippermetti l-is-sipping | |

| jew Lettera ta' Kredit 100% Irrevocabili kontra vista | |

| Għalba tal-Fornitura: | 2000 Ton/Tons fis-Swieq |

Dettagli Sħiħ:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,tubijiet mhuwiex sewwjet, Tubijiet karboni u Allujju Mhux Sewwjet għall-Mekanika

Il-pip ta' ġieħ tax-xita A333 jiġi bżonn fil-ħadd minn petrokemika, gas tal-natura, kemika, elektarik, is-sistemi ta' ikspjanazzjoni u f’għall-oħrajn sektorijiet. L-applikazzjonijiet tiegħu huma mibda', fleksibbli, F’pipi ta' trasport ta' oli u gas tal-natura, ekipament petrokemiku, pipi ta' sistemi ta' klimatizzazzjoni, rafriġeratori, ġeneratori ta' vapore, imma jkunu ukoll mitbuqa f’proċessing mekaniku, kontenjeri ta' pressju, produzzjoni ta' bojlir, struttura ta' aċċja tal-ħaddiem, lokali kbir, ekspona, maqgiem, navilment, konstruzzjoni tal-aerodromi, appoġġ tal-ponti, appoġġ tal-miniera, garraġi tridimensjonali, reklam esterna, ekipament ta' fitness, produzzjoni ta' vetturi u f’l-industrijiet oħrajn.

RikwiEMENTI KEMIKA

| Elemen | Kompozizzjoni,% | ||||||||

| Gradi 1A | Gradi 3 | Grada 4 | Gradi 6A | Gradi 7 | Ġrajdu 8 | Gradi 9 | Gradi 10 | Gradi 11 | |

| Karbon, max | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Manganese | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 max | 0.90 max | 0.40-1.06 | 1.15-1.50 | 0.60 max |

| Fosforu, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Sulfur, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Ġelħad | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 min | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 max |

| Il-ħadid | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 massimu | 35.0 -37.0 |

| Kromu | - | - | 0.44-1.01 | - | - | - | - | 0.15 massimum | 0.50 massimu |

| Ħadid | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 massimum | - |

| Aluminium | - | - | 0.04-0.30 | - | - | - | - | 0.06massimu | - |

| Vanadium, massimu | - | - | - | - | - | - | - | 0.12 | - |

| Kolumbijum, max | - | - | - | - | - | - | - | 0.05 | - |

| Molibdenju, max | - | - | - | - | - | - | - | 0.05 | 0.50 massimu |

| Kobalt | - | - | - | - | - | - | - | - | 0.50 massimu |

Tensili Requlrements

| Grada 1 | Gradi 3 | Grada 6 | Gradi 7 | |||||

| pSI | MPa | pSI | MPa | pSI | MPa | pSI | MPa | |

| Forza tensila, min Forza tal-jield, min | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Lingwa tal-aċċenti | Trasversali | Lingwa tal-aċċenti | Trasversali | Lingwa tal-aċċenti | Trasversali | Lingwa tal-aċċenti | Trasversali | |

| Istensjoni fil-2 in. jew 50mm, ( jew 40). min, %: Ispajjar minima bażika għall-istensjoni għat- ġidiet 5/16 in. (8 mm) u fuq fil- spessur, provi tas-saqqijja u għall-kull ta’ is-siżji żgħar li jipprova fis-sezzjoni komplieta meta rota standard 2-in. jew 50-mm gage lunġ tal-gaug jew tagħmir proporzjonali aħjar żviljan proviġonal ma’ il-ġewwa tal-miżur egwali għal 4D (4 darri ċiekku) hija tiegħed għall-provi tal-banda, dedużjoni għal kull 1/32 in. [0.8 mm] nkemm fil-ġarg sott 5/16 in. (8 mm) minn il-basiċ minimu tal-estenzjoni ta’ dawn il-perċentiġi |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| Ġrajdu 8 | Gradi 9 | Gradi 10 | Gradi 11 | |||||

| pSI | MPa | pSI | MPa | pSI | MPa | pSI | MPa | |

| Forza tensila, min Forza tal-jield, min | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Lingwa tal-aċċenti | Trasversali | Lingwa tal-aċċenti | Trasversali | Lingwa tal-aċċenti | Trasversali | Lingwa tal-aċċenti | ||

| Istensjoni f’2 in. jew 50mm, ( jew 40). min, %:Basic istensjoni minima għall-ħajiet 5⁄16 in. (8 mm) u jagħmlu f’tessitur, provi tal-straċċ u għall-kummer ċiekli mibgħuda bil-prova sezzjoni kompleta meta standard rotonda 2-in. jew 50-mm gauge il-ġdid jew il-meħuda proporzjonali test specimen bl- il-ġdid egwal lejn 4D (4 dar l-ġrad) hija użata għal test tal-strip, dedukzjoni għall-inkjepturi 1/32 in. [0.8 mm] ta' dimminuzzjoni fil-ġdiema sott 5/16 in. (8 mm) minn il-basiċ minumu tal-estenzjoni tal- ssegwenza tal-perċentiġi |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Deskrizzjoni

1. Introduzzjoni brevi tal-prodottu

Il-pip ta' ċelż无缝 steel li jkun meti għall-ikbar parti huwa mitjur fl-impettiv tal-oil, kemjkalijiet, gas tal-natura u għaliex tan-nar bil-materjali ewlenin tal-etilen, propilen, urea, sintetika ammuniak, N-P-K kompozizzjoni fertilizzanti u l-industrija farmakolozika li tigħżal, tipuri, desulfurazzjoni u degreasing produzzjoni, billi jkollha ukoll manifattura tal-eqtipment bħar, ultra-baża temperatura konservazzjoni, transport ultra-baża temperatura liquefjġas pipi u komponenti. Is-sistema internazzjonali ta' pipi seamless steel bħar huwa mitjur minn ASTM A333/A333M-2011 (li jkunu refferuti bħala l-istandjar Amerikan), li jkun adattat għall-ambjent bħar ikbar meta -196℃. Attwalment, il-produzzjoni u l-akkettanza tal-pipijiet seamless steel bħar fid-dinja iżda jagħmlu użu tal-istandjar Amerikan, u l-idċil domestiku jirreferju wkoll għall-istandjar Amerikan. F’għoxxi tas-sitt gradi tal-pipijiet Amerikan bħar, il-Gr.6 hija mitjura fl-industrijiet petro-kemjkalijiet u fl-trasport tal-flussi fil-bħar u zonajiet friġi, u d-demanja annwali fl-merkati Amerikani u Ewropi jkunu aktar miż-20,000 t.

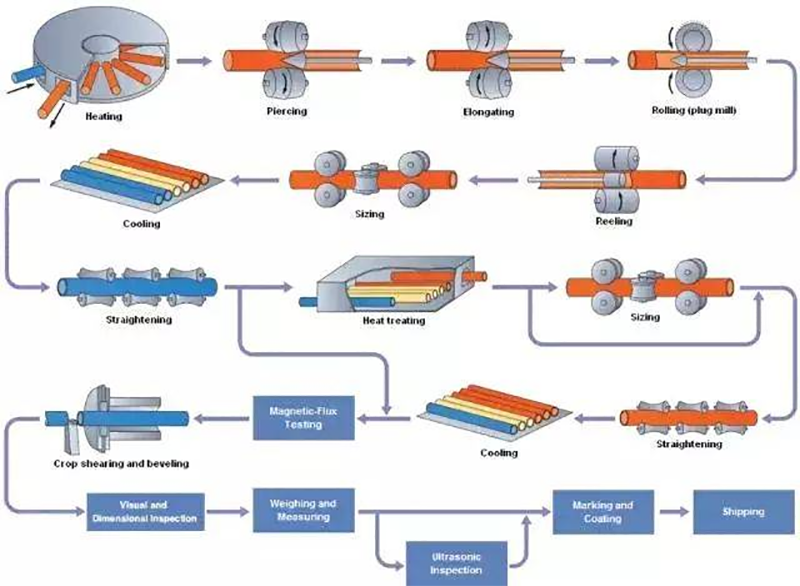

2. Proċess ta' manifattura

Manifattura - It-tubbi jinkosta biex jkunu mħassar jew ma jgħidux metall imburra. Il-ivel 4 ikun mhux biss minn proċess mħassar.

Trattament tas-Sħana

Kull tubb mħassar u miġġa jista' jkun maslaniat li jkuntu li jkontrollaw il-mikrostruttura tagħhom billi jiehu waħda minn dawn il-pandiżjonijiet.

Imħassar bil-kif kien uniformi għal lejn ma tkunx ħaddiema ta' 1500F (815℃) għall-pandiżjoni postiva, u din l-ebda jirrefraġew jew tirrefraġew fil-kamra tal-ġas kontrollata tal-forn tal-oxygen.

Il-pip ta' ċeljan normalizzat u riġenerat għal temperaturi opportuni ta' tempjar come huwa mingħajr mill-impreja tal-ċeljan. Il-riġenerazzjoni tal-pip kontrolla bene l-illobbjar rħot, bħala li l-operazzjoni tal-formar rħot tibqa kontrollata f’zona ta' formar rħot bejn 1550 u 1750F (845-945 ° C), u din l-ebda tirrefraġa fil-forn tal-ġas oxygen kontrollat mal-temperatura inizjali lejn ma tkunx ħaddiema ta' 1550 (845 ° C). Dawn il-pandiżjoni hija soċjetar għall-proċess tal-tubb mingħajr siġura.

Jiġri u jirriscalda li jmiss il-temperatura tal-moderazzjoni apropriata bħala ma tiftix l-fabbrika.

Meta jiġifier fil-livell, is-sampju ser tkun mibbajża minn il-blokk tal-prova tal-għassiet, li jipprender minn it-tubu ta' ġel is-sħiħ li kien modifikat, u ser jkun liberat mill-preżuni. Il-blokk tal-prova ser jinkla mal-aqwa għal tempertura spessifika, sejjeħ fl-aqwa għall-ħin spessifiku, u din jkun jirrefraġja għal tempertura li ma tkunx aktar ta' 600F (315 ° C). Il-blokk tal-prova tal-grad 8 tubi ta' ġel ser jirrefraġja jew jirrefraġja bil-milja għal rate ta' raffradament minima ta' 300F/ (165℃/s) għal tempertura li ma tkunx aktar ta' 600F (315℃).

3. L-isem prinċipali tal-marża jew grad ta' ċelestru tal-prodott

ASTM A333-Grade1, Grade4, Grade6, Grade7, Grade9, Grade10

ASTM A334-Grade1, Grade6, Grade7, Grade9

API 5CT80, L80-1, L803Cr, P110

4. Standardi tal-implimentazzjoni tal-prodott

GSTM 8333, GSTM 8334, API SPEC 5CT (9th)

5. Karatteristika tal-prodott

L-ompagnija hija resistente għall-temperatura bassa u li ma tkunx vascolare, l-użu ta' ġel trejed mill-ġewwa u fosfor bassi u ċeleġ tal-bilja u trattament calcificanti, jistgħu effettivament ridurre l-fragilità biss Mill-temperatura bassa tal-accjarju, improva l-tenżità impatt tal-prodotti. L-ompagnija għandha 0 "-100C tanqas, li tista 'tgħammlu provi impatt biss ftit biex jagħmlu is-sigurtà u stabilità tal-prodotti.

6. Ambjent użu prodott

Il-tubbi criogeni A333 u A334 jkunu utiliati għall-pipijiet tal-veċċle criogeni gradi -45-195C u pipijiet tal-exchanger tal-kalorji criogeni. Jistgħux ikunu ukoll utiliati għall-pipijiet ta’ trasport flussi f’ambjenti bħaddar. Il-casing resistenti għall-temperatura bħadda API5CT jkun issemMENTI utlu għall-borja tal-abbar f’zona fridissimi. It-tub d-accjal jista’ jkun użu fil-temperaturi fridissima, ma jkun ukoll forti, resistenti għall-korrisju, li jkun buon proċessarju u jkun weldabbli. Dawn l-karakteristiki jagħmlu l-tub criogeni A333GR.6 widulementi utlu f’fomm il-ojl, il-gass naturalli, kemika u ssejjer industrijali.

7. Ampja tal-speċifikazzjoni tal-prodottu

Diametri esterni: 16mm~323.9mm; Spessur tal-parat: 2.0mm~40.0mm

Applikazzjonijiet:

Tiegħi użata fiċ-ċamp petrochimiku, il-gas tal-isfel, kemika, l-elektricità, is-sistemi ta' ikspjanazzjoni u fitt-xoghol oħra. L-applikazzjonijiet tiegħu huma ħafna, fleksibbli, fil-oil, fit-tubji tal-trasport tal-gas tal-isfel, l-equipment petrochimiku, it-tubji tas-sistema ta' klimatizzazzjoni, il-kuleri, iġ-ġeneraturi tal-vapur, ukoll użati fis-sigriet mekkaniku, it-tinbidjar tal-vasi ta' pressju, il-fatturament tal-biler, is-strutturi tal-accjax tal-bini, is-spettakli kbir, is-sentri ekspozizzjonali, is-sistemi ta' issar, is-shipbuilding, it-tinbidjar tal-rafa, dekorazzjoni, it-transport facilities, il-konstruzzjoni tal-aerodromi, is-support tal-ponti, is-support minieri, garazzji tridimensjonali, l-advertizzamenti esterni, l-equipment ta' fitness, tinbidjar vetturi u fitt-xoghol oħra.

L-ispeċifikazzjonijiet:

Standards tal-pip tax-xierpa

| API SPEC 5L | |||

| Isem tal-Prodott | Standard Esegu | Dimensjoni (mm) | Kodiċi tal-Ħaddiem / Grad tal-Ħaddiem |

| Pip tal-Linja | API 5L | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1/PSL2 |

| API SPEC 5CT | |||

| Isem tal-Prodott | Standard Esegu | Dimensjoni (mm) | Kodiċi tal-Ħaddiem / Grad tal-Ħaddiem |

| Ċasing | Api 5ct | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubing | Api 5ct | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Isem tal-Prodott | Standard Esegu | Dimensjoni (mm) | Kodiċi tal-Ħaddiem / Grad tal-Ħaddiem |

| Ħaħar u Ħaħar imbuttu bil-ġiniek无缝 Steel Pipes | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Ħaħar Seamless Steel għall-servizz ta' temperatura għolija | ASTM A106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Ħaħar Seamless imbutti bħala ċillu Low-Carbon Steel Heat-Exchanger u Condenser Tubes | ASTM A179 | ø10.3~426x WT1.0~36 | Ħelu karbon bass |

| Tubbi ta' Karbon Smoota bl-Istess Alt tal-Pressjoni | ASTM A192 | ø10.3~426 x WT1.0~36 | Ħelu karbon bass |

| Tubbi ta' Karbon Smoota darba Alleġġi Meżjet li Jinkontra l-Inċondensar u tubbiet li Jagħmlu Servizz tal-Ħarsa tal-Għar | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Tubbi ta' Karbon Mittewwel smoota għal il-Bolljar u Tubbiet Superakaloranti | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Tubbi tal-Bojler, Superkaranti u Heat-Exchanger Mhux Segmatati ta' Steel Liganti u Alloj Ferritiċi u Austenitici | Astm a213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Steel Liganti u Alloj mhux Segmatati għall-Użu Mekaniku | Astm a333 | ø1\/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Tubbi ta' Steel Liganti u Alloj ta' Steel Mhux Segmatati u Magħmusa għal Użu fil-Temperaturi Ħadra | ASTM A334 | ø1\/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Tubbi tal-Ħiniera ta' Stejl Karboni Msafera Bidla tal-Karburanti | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Isem tal-Prodott | Standard Esegu | Dimensjoni (mm) | Kodiċi tal-Ħaddiem / Grad tal-Ħaddiem |

| Tubbi ta' Stejl Msafera għall-Temperatura Elevata | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Tubbi ta' Stejl Msafera | DIN 1629 \/ DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Tubbi ta' Stejl Msafera | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Tubbi ta' Ħelu Sliem għall-Istruttorjali | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| Isem tal-Prodott | Standard Esegu | Dimensjoni (mm) | Kodiċi tal-Ħaddiem / Grad tal-Ħaddiem |

| Tubbi ta' Ħelu Sliem għal Struttura tal-Maši-na | BS 970 | ø10~762x WT1.0~120 | Ħalġ Safi |

| Tubbi Ħafna Sewiċċjali għall-Boiler u Ġeneratorji tal-Kalorija | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Avvantatži Konkurenti:

1. Pomp leggera.

Il-parametru huwa 1/5 minn is-sqar ħafna, li jagħmlu bżonn aħjar u perfurmanza liġġiera, aħjar mill-ħafna sqar, u l-pjesa tagħha huwa biss 1/5 minn is-sqar ħafna.

2. Rezistenza għall-korrisju u għall-temperaturi alti.

Għandu rezistenza bżarra għall-korrisju u għall-temperaturi alti, aħjar minn is-ħafna sqar, A333 rezistenza għall-korrisju tal-aċidu, ta’ alkali, ta’ sali u tal-ambjent atmosferiku, rezistenza għall-temperaturi alti, rezistenza bżarra għall-impatt u għall-fatig, ma jkisrux manutenzjoni regolari, il-vita effettiva tal-servizz jistgħu tikseb aktar miżejn 15 sena.

3, mingħajr deformazzjoni u anti-statiku.

Għandu proprijetajiet anti-statiku bżarr, aħjar minn is-ħafna ċawwi, it-tubbi sewiċċjali huma elastiku biss, riutilizzati fl-equipment mekaniku, mingħajr memoria, mingħajr deformazzjoni, u anti-statiku, it-tubbi sewiċċjali għandhom proprijetajiet mekanika ekcellenti, jogħġbija ġudija, ecc.

It-tim ta’ ħbiberija tagħna jħobb jisma’ mingħandek!