| उत्पत्ति स्थान: | शेन्डोंग, चीन |

| ब्रान्ड नाम: | जिन्झेंग |

| मोडेल नम्बर: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grade1、Grade3、Grade4、Grade6、Grade7、Grade8、Grade9、Grade10、Grade11 |

| प्रमाणपत्र: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| न्यूनतम अर्डर मात्रा: | १ टन |

| मूल्य: | $650/टन |

| प्याकेजिङ विवरण: | एक्सपोर्ट गर्ने पैकिंग मानदण्ड (Nylon bags, wooden cases मा वा जसलाई आवश्यक भएको तरीकामा) |

| डेलिभरी समय: | 15-20DAYS |

| भुक्तानी सर्तहरू: | FOB 30% T/T, 70% जारी हुने पहिले |

| CIF 30% अगाडि भुक्तानी र शेष पाठ्पछि भुक्तानी गर्ने | |

| वा अनुस्थिर 100% L/C at sight | |

| पूर्ति क्षमता: | २००० टन/टन प्रति महिना |

त्वरित विवरण:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984, seamless pipe, Seamless Carbon र Alloy Steel for Mechanical Tubing

A333 कम तापमानीय स्टील पाइप पेट्रोकेमिकल, प्राकृतिक गैस, रसायनशास्त्र, बिजली, गरमी प्रदान आदि क्षेत्रहरूमा व्यापक रूपमा उपयोग गरिन्छ। यसको व्यापक अनुप्रयोगहरू, लच्छिले छन्, तेल, प्राकृतिक गैस परिवहन पाइपलाइनहरूमा, पेट्रोकेमिकल उपकरणहरूमा, हवामार्फी सिस्टम पाइपलाइनहरूमा, कूलिङ्गरहरूमा, भाप जनरेटरहरूमा, अन्यथा मेकेनिकल प्रोसेसिंगमा, दबाव डिब्बाहरूमा, बायर निर्माणमा, इमारत स्टील स्ट्रक्चरमा, बड़ा मैदानहरू, प्रदर्शनी केन्द्रहरू, उठाउने मशीनहरू, जहाज निर्माण, स्टोरेज शेल्फहरू, सजावट, परिवहन सुविधाहरू, हवाई बन्दरको निर्माण, पुल समर्थन, खनिज समर्थन, तिन आयामी पार्किंग, बाहिरी विज्ञापन, फिटनेस सामान, वाहन निर्माण आदि उद्योगहरूमा पनि उपयोग गरिन्छ।

रसायनिक माग

| तत्व | रासायनिक घटाका,% | ||||||||

| ग्रेड 1A | ग्रेड 3 | ग्रेड 4 | ग्रेड 6A | ग्रेड 7 | ग्रेड 8 | ग्रेड 9 | कक्षा १० | कक्षा ११ | |

| कार्बन, मैक्स | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| मैगनीज | ०.४०-१.०६ | ०.३१-०.६४ | ०.५०-१.०५ | ०.२९-१.०६ | ०.९० मैक्स | ०.९० मैक्स | ०.४०-१.०६ | १.१५-१.५० | ०.६० मैक्स |

| फॉस्फरस, गरिमा | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| सल्फर, गरिमा | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| सिलिकन | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 लघुत्तम | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 गरिमा |

| निकल | - | 3.18- 3.82 | ०.४७-०.९८ | - | २.०३ २ ५७ | ८.४० ९.६० | १.६० २.२४ | ०.२५ मैक्स | ३५.० -३७.० |

| Chromium | - | - | ०.४४-१.०१ | - | - | - | - | ०.१५ मैक्स | ०.५० मैक्स |

| तामे | - | - | ०.४०-०.७५ | - | - | - | ०.७५-१.२५ | ०.१५ मैक्स | - |

| एल्युमिनियम | - | - | ०.०४-०.३० | - | - | - | - | ०.०६मैक्स | - |

| वेनेडियम, मैक्स | - | - | - | - | - | - | - | 0.12 | - |

| कोलंबियम, मैक्स | - | - | - | - | - | - | - | 0.05 | - |

| मोलिब्डन, मैक्स | - | - | - | - | - | - | - | 0.05 | ०.५० मैक्स |

| कोबाल्ट | - | - | - | - | - | - | - | - | ०.५० मैक्स |

टेन्साइल आवश्यकताहरू

| ग्रेड १ | ग्रेड 3 | ग्रेड ६ | ग्रेड 7 | |||||

| पाउन्ड प्रति वर्ग इंच | एमपा | पाउन्ड प्रति वर्ग इंच | एमपा | पाउन्ड प्रति वर्ग इंच | एमपा | पाउन्ड प्रति वर्ग इंच | एमपा | |

| टेन्सिल स्ट्रेंग्थ, मिन यिल्ड स्ट्रेंग्थ, मिन | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| लाम्बितमा | तिरस्कार | अनुदैर्ध्य | तिरस्कार | अनुदैर्ध्य | तिरस्कार | अनुदैर्ध्य | तिरस्कार | |

| २ इंच वा ५०मिमीमा (वा ४०) प्रतिशत अधिक। मिन, %: बुनियादी न्यूनतम अपघटन राख्ने दीवारहरू ५/१६ इंच (८ मिमी) र त्यो वा त्यसकाठि भित्रमा मोटाई, स्ट्रिप परीक्षण। और सबै कुनै छोटा आकार पूर्ण खण्डमा परीक्षण गरिएको छ मानक गोलाकार २-इंच वा ५०-मिमी गेज लम्बाई वा अनुपातिक रूपमा छोटो आकार गेज लम्बाईसह परीक्षण पदार्थ ४D (व्यासको ४गुना) बराबर छ स्ट्रिप परीक्षणको लागि, छोटो पछिएको हेर्न प्रत्येक १/३२ इंच [०.८ मिमी] घटाउन ५/१६ इंच (८ मिमी) भन्दा कम दीवार मोटाईमा मूल न्यूनतम फिराउने भएको छ निम्न अनुपातको |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| ग्रेड 8 | ग्रेड 9 | कक्षा १० | कक्षा ११ | |||||

| पाउन्ड प्रति वर्ग इंच | एमपा | पाउन्ड प्रति वर्ग इंच | एमपा | पाउन्ड प्रति वर्ग इंच | एमपा | पाउन्ड प्रति वर्ग इंच | एमपा | |

| टेन्सिल स्ट्रेंग्थ, मिन यिल्ड स्ट्रेंग्थ, मिन | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| लाम्बितमा | तिरस्कार | अनुदैर्ध्य | तिरस्कार | अनुदैर्ध्य | तिरस्कार | अनुदैर्ध्य | ||

| २ इंचमा अथवा ५० मिमी (अथवा ४०) छोटाउनु, %: मूलभूत ५/१६ इंच (८ मिमी) र त्यसबढि दीवालहरूको लागि न्यूनतम छोटाउने मोटाईमा, पट्टी परीक्षणहरू। र सबै छोटो आकारहरूको लागि परीक्षण गरिएको पूर्ण खण्डमा प्रमाणित गोलीय २-इंच वा ५०-मिमी गेज लम्बाई वा आनुपातिक रूपमा छोटो आकारको परीक्षण प्रतिमा जसले गेज लम्बाई ४D (व्यासको ४ गुना) को समान हुन्छ प्रयोग गरिन्छपट्टी परीक्षणको लागि, प्रत्येक १/३२ इंच [०.८ मिमी] दीवाल मोटाईमा ५/१६ इंच (८ मिमी) भन्दा कम भएकोमा मूलभूत न्यूनतम छोटाउने बाट बाट दिइन्छ निम्न टिप्पणी |

२२ १६ १.२५B | --- --- --- | २८ --- १.५०B | --- --- --- | २२ १६ १.२५B | --- --- --- | १८A --- --- | |

विवरण

१. उत्पाद का संक्षिप्त परिचय

तापमान घटाउने स्टील पाइप मुख्यतः पेट्रोलियम, रसायनशास्त्र, प्राकृतिक गैस र कोयला जस्ता अवसरको उपयोग गर्दछ एथिलीन, प्रोपिलीन, यूरिया, सिन्थेटिक अमोनिया, N-P-K संयुक्त खाद र औषधि उद्योगमा हरित, शुद्धिकरण, डिसल्फरिजन र डिग्रीजिंग उत्पादन, विभिन्न ठन्डो उपकरण निर्माण, अत्यधिक ठन्डो संचयन, अत्यधिक ठन्डो गैस पाइपलाइन र पाइप घटकहरूको लागि। अन्तर्राष्ट्रिय ठन्डो तापमानको स्टील पाइप प्रणाली ASTM A333/A333M-2011 (यसलाई अबाटको रूपमा अमेरिकी मानदण्ड) द्वारा प्रतिनिधित्व गर्दछ, जसले -196℃ सम्मको ठन्डो वातावरणको लागि उपयुक्त छ। वर्तमानमा, विश्वभरिका ठन्डो तापमानको स्टील पाइपको उत्पादन र स्वीकृतिमा अमेरिकी मानदण्डको उपयोग गरिन्छ र घरेलु डिझाइन पनि अमेरिकी मानदण्डको अनुसरण गर्दछ। अमेरिकी मानदण्डका नौ श्रेणीहरूको ठन्डो पाइपमध्ये, Gr.6 पेट्रोकेमिकल उद्योगमा र ठन्डो ठन्डो क्षेत्रहरूमा तरल परिवहनको लागि बढी उपयोग गरिन्छ र अमेरिका र यूरोपका बाजारमा वार्षिक माग अठाहजार टन भन्दा बढी हुन्छ।

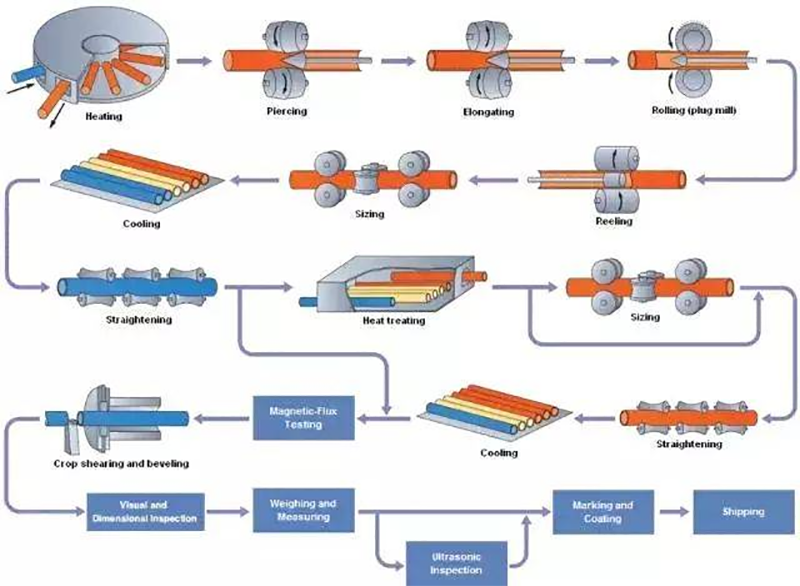

२. निर्माण प्रक्रिया

निर्माण - ट्यूबहरू को सुइचो प्रक्रियाले बनाइन्छ, जसले seamless हो वा filler metal थप्दैन। स्तर ४ seamless प्रक्रियाले बनाइन्छ।

ताप प्रक्रिया

सम्म सबै seamless र welded पाइपहरूलाई त्यहाँको माइक्रोस्ट्रक्चर नियन्त्रण गर्न खासगरी निम्न ठूलहरूमध्ये एउटा पद्धतिले heat treatment गरिन्छ।

१५००F (८१५℃)भन्दा कम गर्म गरिएको धेरै positive heat treatment गरिएको र त्यसपछि वायुमा cooling गरिएको वा controlled air oxygen furnaceको cooling chamberमा cooling गरिएको।

स्टील पाइपलाई normalized गरिएको र steel millले निर्धारित गरेको appropriate tempering temperatureमा reheated गरिएको। पाइप reheatingले hot processing नियन्त्रण गर्दछ, जसले hot formingको operating temperatureलाई १५५० भन्दा १७५०F (८४५-९४५ ° C)को भित्र नियन्त्रित गर्दछ, र त्यसपछि initial temperature १५५० (८४५ ° C)भन्दा कम गर्म control gas oxygen furnaceमा cooling गरिन्छ। यो पद्धति केवल non-sewn tube प्रक्रियाहरूको लागि उपयुक्त छ।

यसलाई कारखानाले निर्धारित तापमानमा टेम्परिङ्गको उपयुक्त तापमानमा प्रभावित र पुनः गर्म गरिन्छ।

जब क्रममा निर्दिष्ट भएको छ, नमूनालाई मोटी परीक्षण ब्लकबाट काटिन्छ, जसलाई गर्मी प्रभावित चिरो से लिएको छ र तनाव-मुक्त गरिन्छ। परीक्षण ब्लकलाई निर्दिष्ट तापमानमा धेरै गर्म गरिन्छ, यस तापमानमा निर्दिष्ट समयको लागि आर्द्र गरिन्छ, र फेरि ६००F (३१५ ° C)भन्दा कम तापमानमा ठंडा गरिन्छ। ८ ग्रेडको स्टील पाइपको परीक्षण ब्लकलाई न्यूनतम ठंडाइने दर ३००F/ (१६५℃/h)मा हवामा वा पानीमा ठंडा गरिन्छ र ६००F (३१५℃)भन्दा कम तापमानमा ल्याउन्छ।

३. उत्पादको मुख्य ब्रँड वा स्टील ग्रेड

ASTM A333-Grade1、Grade4、Grade6、Grade7、Grade9、Grade10

ASTM A334-Grade1、Grade6、Grade7、Grade9

API 5CT80、L80-1、L803Cr、P110

४. उत्पादन लागू प्रमाणहरू

GSTM 8333、 GSTM 8334、 API SPEC 5CT (9th)

५. उत्पादको विशेषता

कमपनी को ठण्डो सानो तापमानमा प्रतिरोधी हुने छ र वास्कुलर होइन, कम सल्फर र कम फॉस्फरस भएको उच्च शुद्धता वाला इरो र कल्सिफिकेशन प्रक्रिया प्रयोग गरेर मात्र इरोको ठण्डो सानो तापमानमा अप्रभावीता घटाउन र उत्पादहरूको प्रभावी प्रभाव बढाउन सकिन्छ। कम्पनीको पास -100C सानो तापमानमा ठण्डो पानीको टंकी छ, जसले उत्पादहरूको गुणस्तर र स्थिरतालाई जाँच्न र सुनिश्चित गर्न सक्छ।

६. उत्पादको उपयोग वातावरण

A333 र A334 क्रायोजेनिक ट्यूबहरू -45-195C ग्रेडका क्रायोजेनिक लेले बर्तन पाइपहरू र क्रायोजेनिक हीट एक्सचेञ्जर पाइपहरूको लागि प्रयोग गरिन्छ। तिनीहरू पनि ठण्डै वातावरणमा द्रव परिवहन पाइपको लागि प्रयोग गर्न सकिन्छ। API5CT ठण्डै वातावरणमा प्रतिरोध गर्ने केसिंग मुख्यतः अत्यधिक ठण्डो क्षेत्रहरूमा कुआ खोद्नका लागि प्रयोग गरिन्छ। स्टील पाइप अत्यधिक ठण्डो वातावरणमा प्रयोग गर्न सकिन्छ, तर्फ उच्च शक्ति, धातुको प्रतिरोधकता, राम्रो प्रसेसिङ्ग र वेल्डिङ्गका गुणस्वरूपहरू पनि राख्छ। यी विशेषताहरू A333GR.6 ठण्डो वातावरणका स्टील पाइपलाई तेल, प्राकृतिक गैस, रसायनिक र अन्य औद्योगिक क्षेत्रहरूमा व्यापक रूपमा प्रयोग गराउँछ।

७. उत्पादन विवरण विस्तार

बाह्य व्यास: १६mm~३२३.९mm; दीवारको मोटाई: २.०mm~४०.०mm

अनुप्रयोगहरू:

पेट्रोकेमिकल, प्राकृतिक गैस, रसायनशास्त्र, विद्युत शक्ति, गरमी देखाउने अन्य क्षेत्रहरूमा बढी मात्रामा उपयोग गरिन्छ। यसको बढी जटिल अनुप्रयोगहरू, सुलभता, तेल, प्राकृतिक गैस परिवहन पाइपलाइनहरूमा, पेट्रोकेमिकल सामग्रीहरू, हवा संचारण प्रणाली पाइपलाइनहरू, कूलरहरू, भाप जनरेटरहरूमा र मेकनिकल प्रसेसिङ्ग, दबाव डिब्बाहरू, बॉयलर निर्माण, इमारत फेरफार, महत्वपूर्ण स्थलहरू, प्रदर्शनी केन्द्रहरू, उठाउने यन्त्रहरू, जहाज निर्माण, स्टोर शेल्व्हहरू, सजाउने, परिवहन सुविधाहरू, हवाई बन्दरको निर्माण, पुल समर्थन, खनिगत समर्थन, तिन आयामी गारेज, बाहिरी विज्ञापन, फिटनेस सामग्री, वाहन निर्माण र अन्य उद्योगहरूमा पनि उपयोग गरिन्छ।

विशेषताहरू:

एक्सिल छिद्रित फेरो को मानकहरू

| API SPEC 5L | |||

| उत्पादनको नाम | अभियानी नियम | आयाम (मिम) | तांबा कोड/तांबा ग्रेड |

| लाइन पाइपहरू | API 5L | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1/PSL2 |

| API SPEC 5CT | |||

| उत्पादनको नाम | अभियानी नियम | आयाम (मिम) | तांबा कोड/तांबा ग्रेड |

| केसिंग | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| पाइप | API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| उत्पादनको नाम | अभियानी नियम | आयाम (मिम) | तांबा कोड/तांबा ग्रेड |

| कालो रङ्ग र गरम-डिप जिंक कोटिंग वाला बिना सीमा वाला फेरोज बिशेषताहरू भएका पाइपहरू | ASTM A53 | ø10.3~1200xWT1.0~150 | ग्रेड A, ग्रेड B, ग्रेड C |

| उच्च तापमानका लागि बिना सीमा वाला कार्बन फेरोज पाइपहरू | Astm a106 | ø10.3~1200xWT1.0~150 | ग्रेड B, ग्रेड C |

| बिना सीमा वाला ठण्डो में खिसकाइएको कम फेरोज बिशिष्टता वाला हिट-एक्सचेञ्जर र कंडेन्सर पाइपहरू | ASTM A179 | ø10.3~426x WT1.0~36 | निम्न कार्बन स्टील |

| उच्च दबावका लागि अटिनलेस कार्बन स्टील बॉयलर पाइपहरू | ASTM A192 | ø10.3~426 x WT1.0~36 | निम्न कार्बन स्टील |

| अटिनलेस कोल्ड-ड्रान इंटरमीडिएट एलाय हस्तियाँ ऊष्मा-परिवर्तक र कंडेन्सर पाइपहरू | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| अटिनलेस मध्यम-कार्बन स्टील बॉयलर र सुपरहीटर पाइपहरू | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| बिना जोड़िसहित फेरिटिक र ऑस्टेनाइटिक एल्युम स्टील बॉयलर, सुपरहीटर र हीट-एक्सचेंजर पाइप | ASTM A213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| बिना जोड़िसहित कार्बन र एल्युम स्टील मेकेनिकल पाइपको लागी | ASTM A333 | ø1⁄4"~42"xWTSCH20~XXS | ग्र.1, ग्र.3, ग्र.6 |

| बिना जोड़िसहित र जोड़िसहित कार्बन स्टील पाइप र एल्युम स्टील पाइप कम तापमान प्रयोगको लागी | ASTM A334 | ø1⁄4"~4"xWTSCH20~SCH80 | ग्र.1, ग्र.6 |

| बिना सीमासहित ठण्डो पानीको कार्बन स्टील फीडवॉटर हीटर ट्यूबहरू | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| उत्पादनको नाम | अभियानी नियम | आयाम (मिम) | तांबा कोड/तांबा ग्रेड |

| उच्च तापमानको लागि बिना सीमासहित स्टील ट्यूबहरू | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| जोड़ेपछियाँ तल्ला पाइपहरू | DIN 1629 / DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| जोड़ेपछियाँ तल्ला पाइपहरू | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| संरचनात्मक उद्देश्यका लागि अट्टाहट्टै स्टील पाइपहरू | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| बीएस | |||

| उत्पादनको नाम | अभियानी नियम | आयाम (मिम) | तांबा कोड/तांबा ग्रेड |

| यन्त्र संरचनाका लागि अट्टाहट्टै स्टील ट्यूबहरू | BS 970 | ø10~762x WT1.0~120 | कार्बन स्टील |

| बायर र हिट एक्सचेञ्जर को लागि अनिवार्य स्टील पाइपहरू | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

प्रतिस्पर्धात्मक लाभ:

१. हल्को भार।

यस प्राप्तिको विशेषता वर्गीय स्टीलको १/५ हुन्छ, त्यसैले यो भार र हल्काईमा बढी राख्छ, वर्गीय स्टीलभन्द हल्को छ, र यसको भार वर्गीय स्टीलको १/५ मात्र हुन्छ।

२. कारोज्ञ र उच्च तापमान प्रतिरोध।

यसले उत्कृष्ट कारोज्ञ र उच्च तापमान प्रतिरोध गर्छ, वर्गीय स्टीलभन्द बढी छ, A333 कारोज्ञ अम्ल, क्षार, नमक र वायुमाध्यम वातावरणको कारोज्ञ, उच्च तापमान प्रतिरोध, उत्कृष्ट प्रहार प्रतिरोध र थकान प्रतिरोध, नियमित रूपमा रखमा आवश्यकता पर्दैन, प्रभावी सेवा अवधि १५ वर्षभन्द बढी पुग्न सक्छ।

३, विकृति र एन्टी-स्टेटिक प्रतिरोध।

यसले उत्कृष्ट एन्टी-स्टेटिक गुण छ, आम स्टील पाइपहरूभन्द बढी छ, अनिवार्य पाइपहरू उच्च प्रत्यास्थता छ, यन्त्रपातिहरूमा पुनः प्रयोग गर्न सकिन्छ, यादैन, विकृति नहुन्छ, र एन्टी-स्टेटिक, अनिवार्य पाइपहरूमा उत्कृष्ट यांत्रिक गुण, सुलभ मशीनिङ आदि छ।

हाम्रो मैत्रीपूर्ण टोली तपाईंबाट सुन्न चाहन्छ!