| Plaats van oorsprong: | Shandong, China |

| Merknaam: | jinzheng |

| Modelnummer: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grade1、Grade3、Grade4、Grade6、Grade7、Grade8、Grade9、Grade10、Grade11 |

| Certificering: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| Minimale bestelhoeveelheid: | 1 ton |

| Prijs: | $650/ton |

| Verpakkingsdetails: | Exportverpakkingsstandaard (In bundels Nylon zakken, houten dozen of zoals vereist) |

| Leveringstijd: | 15-20 dagen |

| Betaalvoorwaarden: | FOB 30%T/T, 70% voor verzending |

| CIF 30% voorschot en de rest te betalen voor verzending | |

| of Onherroepelijk 100% L/C tegen zicht | |

| Leveringscapaciteit: | 2000 Ton/Tons per Maand |

Een snelle detail:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,mootloze buis, Mootloze koolstalen en legeringen voor mechanische buizen

A333 lage temperatuurstaalbuis wordt breed toegepast in de petrochemische, aardgas, chemische, elektriciteits-, verwarmings- en andere sectoren. Het heeft een breed toepassingsgebied, is flexibel en wordt gebruikt in olie- en aardgasleidingen, petrochemische apparatuur, airconditioning-systemen, koelpijpen, stoomgeneratoren, maar ook in mechanische verwerking, drukvaten, ketelbouw, bouw van staalconstructies, grote evenementenlocaties, tentoonstellingscentra, hijsmachines, scheepvaart, opslagrekken, inrichting, vervoersmiddelen, luchthaveninfrastructuur, bronsupporten, driedimensionale parkeergarages, buitenreclame, fitnessapparatuur, voertuigbouw en andere industrieën.

Chemische eisen

| Elementen | Samenstelling, % | ||||||||

| Klasse 1A | Klasse 3 | Klasse 4 | Klasse 6A | Klasse 7 | 8e graad | Klasse 9 | Klasse 10 | Klasse 11 | |

| Koolstof, max | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Andere | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 max | 0.90 max | 0.40-1.06 | 1.15-1.50 | 0.60 Max |

| Fosfor, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Zwavel, max | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Silicium | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 min | 013- 0,32 | 0,13 0,32 | - | 0,10-0,35 | 0.35 max |

| Nikkel | - | 3,18- 3,82 | 0,47-0,98 | - | 2,03 2 57 | 8,40 9,60 | 1,60 2,24 | 0.25 Max | 35,0 -37,0 |

| Chromium | - | - | 0,44-1,01 | - | - | - | - | 0.15 max | 0.50 max |

| Koper | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 max | - |

| Aluminium | - | - | 0.04-0.30 | - | - | - | - | 0.06 max | - |

| Vanadium, max | - | - | - | - | - | - | - | 0.12 | - |

| Columbium, max | - | - | - | - | - | - | - | 0.05 | - |

| Molybdeen, max | - | - | - | - | - | - | - | 0.05 | 0.50 max |

| Kobalt | - | - | - | - | - | - | - | - | 0.50 max |

Trekdichtheidseisen

| Klasse 1 | Klasse 3 | Categorie 6 | Klasse 7 | |||||

| psi | Mpa | psi | Mpa | psi | Mpa | psi | Mpa | |

| Treksterkte, min Vervormingssterkte, min | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Lengterichting | Transversaal | Langeafstands | Transversaal | Langeafstands | Transversaal | Langeafstands | Transversaal | |

| Uitrekking in 2 inch of 50mm, (of 40). min, %: Basisminimum uitrekking voor wanden van 5/16 inch (8 mm) en dikker in dikte, baantests en voor alle kleine maten getest in volledige sectie wanneer standaard rond 2-in. of 50-mm meetlat lengte of proportioneel kleinere maat proefmonster met de meetlengte gelijk aan 4D (4 keer de diameter) is gebruikt voor bandtests, een aftrek voor elke 1/32 in. [0,8 mm] afname in wanddikte onder 5/16 in. (8 mm) van de basisminimum uitrekking van het volgende percentage |

35 28 1,75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| 8e graad | Klasse 9 | Klasse 10 | Klasse 11 | |||||

| psi | Mpa | psi | Mpa | psi | Mpa | psi | Mpa | |

| Treksterkte, min Vervormingssterkte, min | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Lengterichting | Transversaal | Langeafstands | Transversaal | Langeafstands | Transversaal | Langeafstands | ||

| Uitrekking in 2 in. of 50mm, (of 40). min, %: Basis minimale uitrekking voor wanden van 5/16 in. (8 mm) en dikker in dikte, strip tests. en voor alle kleine maten getest in volle doorsnede wanneer standaard rond 2-inch of 50-mm meetlengte of proportioneel kleinere formaat proefmonster met de meetlengte gelijk aan 4D (4 keer de diameter) wordt gebruikt Voor strip tests, een aftrek voor elke 1/32 inch [0,8 mm] afname in wanddikte onder 5/16 inch (8 mm) van de basis minimum uitrekking van de volgende percentage |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Beschrijving

1. Product korte introductie

Lage-temperatuur naadloze staalbuizen worden voornamelijk gebruikt in de olie-, chemische-, aardgas- en steenkoolindustrie als grondstoffen voor ethyleen, propyleen, ureum, kunstmest (N-P-K), en de farmaceutische industrie voor reiniging, zuivering, desulfurisatie en ontvettingsproductie, evenals voor de productie van koudeapparatuur, ultralage temperatuuropslag, transport van ultrakoude vloeibare gasleidingen en buisonderdelen. Het internationale systeem van lage-temperatuur naadloze staalbuizen wordt vertegenwoordigd door ASTM A333/A333M-2011 (hieronder aangeduid als de Amerikaanse norm), dat geschikt is voor een lage temperatuuromgeving tot -196℃. Momenteel gebruiken de meeste producenten en accepteert de wereldwijde productie van lage-temperatuur naadloze staalbuizen de Amerikaanse norm, en ook het binnenlandse ontwerp verwijst naar de Amerikaanse norm. Onder de negen typen van de Amerikaanse norm voor cryogeen leidingsysteem wordt Gr.6 breed toegepast in de petrochemische industrie en voor vloeistoftransport in gebieden met lage temperaturen en koude omstandigheden, en de jaarlijkse vraag op de Amerikaanse en Europese markt bedraagt meer dan 20.000 ton.

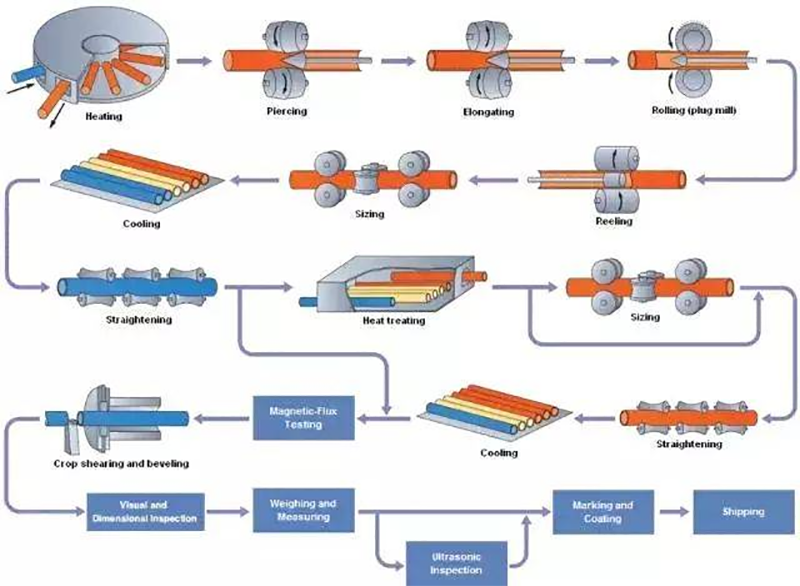

2. Productieproces

Productie - Buizen worden gemaakt door smeewerkprocessen die naadloos zijn of geen vullingsmetaal toevoegen. Niveau 4 moet worden gemaakt met een naadloos proces.

Warmtebehandeling

Alle naadloze en gesmeede buizen moeten worden geheat behandeld om hun microstructuur te beheersen door een van de volgende methoden.

Gelijkmatig verhit tot minimaal 1500F (815℃) voor positieve heatbehandeling, en daarna luchtkoeling of koelen in de koorkamer van de gecontroleerde luchtoxigenoven.

De stalen buis wordt genormaliseerd en opnieuw verhit tot een geschikte temperatuur zoals bepaald door de staalfabriek. Het herverhitten van de buis controleert goed het warme bewerken, zodat de werktemperatuur van het warmvormen binnen het warmvormbereik van 1550 tot 1750F (845-945 °C) wordt gehouden, en daarna wordt gekoeld in de gecontroleerde gasoxigenoven met een begin temperatuur van minimaal 1550 (845 °C). Deze methode is alleen geschikt voor niet-gezewe buisprocessen.

Het wordt behandeld en opnieuw verhit tot de juiste temperatuur zoals bepaald door de fabriek.

Indien in de bestelling aangegeven, moet de steekproef worden afgenomen uit het dikteproefstuk, dat wordt genomen uit de stalen buis van de hittebehandelde steen, en moet spanningsspanning ondergaan. Het proefstuk moet geleidelijk worden verhit tot de gespecificeerde temperatuur, op deze temperatuur vochtig worden gehouden voor de gespecificeerde tijd, en vervolgens gekoeld worden tot een temperatuur niet hoger dan 600F (315 ° C). Het proefstuk van kwaliteit 8 staalbuis moet lucht- of waterkoeling ondergaan met een minimale koelsnelheid van 300F/ (165℃/h) tot een temperatuur niet hoger dan 600F (315℃).

3. Het hoofdmerk of staalsorte van het product

ASTM A333-Grade1、Grade4、Grade6、Grade7、Grade9、Grade10

ASTM A334-Grade1、Grade6、Grade7、Grade9

API 5CT80、L80-1、L803Cr、P110

4. Productimplementatie normen

GSTM 8333、 GSTM 8334、 API SPEC 5CT (9th)

5. Productkenmerk

Het bedrijf is bestand tegen lage temperaturen en niet-vasculair, het gebruik van laagsulfuur- en laagfosforhoogzuivere staal en calcificatietherapie kan effectief de lage temperatuur broosheid van staal verminderen, de impacttaaiheid van producten verbeteren. Het bedrijf heeft 0 "-100C koeltanks, waarmee er batchsgewijs een lage temperatuur impacttest uitgevoerd kan worden om de kwaliteit en stabiliteit van de producten te garanderen.

6. Productgebruikomgeving

De kryogeen buizen A333 en A334 worden gebruikt voor -45 tot -195C klasnkryogene leele vaatbuizen en kryogene warmteomsetterbuizen. Ze kunnen ook worden gebruikt voor vloeistoftransportbuizen in lage temperatuur omgevingen. De API5CT laagtemperatuur bestendige hulsing wordt voornamelijk gebruikt voor boren in extreem koude gebieden. De staalpijpen kunnen worden gebruikt bij extreem lage temperaturen, maar hebben ook hoge sterkte, corrosiebestendigheid, goede bewerkbaarheid en schaafbaarheid. Deze kenmerken maken dat de A333GR.6 laagtemperatuurstaalpijp breed wordt toegepast in olie-, aardgas-, chemische en andere industriële velden.

7. Product specificatie bereik

Buitendiameter: 16mm~323.9mm; Wanddikte: 2.0mm~40.0mm

Toepassingen:

Widely used in petrochemische, aardgas, chemische, elektriciteits-, verwarmingssectoren en andere velden. Zijn brede toepassingen, flexibel, In olie- en aardgasvoerbuizen, petrochemische apparatuur, airconditioning systeemleidingen, koelers, stoomgeneratoren, maar ook gebruikt in mechanische verwerking, drukvaten, ketelbouw, bouw van staalstructuren, grote evenementenlocaties, tentoonstellingscentra, hijsmachines, scheepsbouw, opslagplanken, decoratie, transportmiddelen, luchthaveninfrastructuur, bronsupporten, mijnsupporten, driedimensionale parkeergarages, buitenreclame, fitnessapparatuur, voertuigbouw en andere industrieën3

Specificaties:

Normen voor naadloze stalen buis

| API SPEC 5L | |||

| Productnaam | Uitvoeringsnorm | Afmeting (mm) | Staalcode / Staalklasse |

| Leidingbuizen | Api 5l | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API-SPEC 5CT | |||

| Productnaam | Uitvoeringsnorm | Afmeting (mm) | Staalcode / Staalklasse |

| Behuizing | Api 5ct | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Buis | Api 5ct | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Productnaam | Uitvoeringsnorm | Afmeting (mm) | Staalcode / Staalklasse |

| Zwarte en warm-galvaniseerde naadloze staalbuizen | Astm a53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Naadloze koolstalen buizen voor hoge temperatuurtoepassingen | Astm a106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Naadloze koudgetrokken laagkoolstalen warmte-omzetter- en condensatorbuisjes | ASTM A179 | ø10.3~426x WT1.0~36 | Lage-koolstalen |

| Naadloze koolstalen ketelbuizen voor hoge druk | ASTM A192 | ø10.3~426 x WT1.0~36 | Lage-koolstalen |

| Naadloze koudgetrokken tussenliggende legeringsstalen warmte-uitwisselaar- en condensatorbuizen | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Naadloze medium-koolstofstaal ketel- en superheaterbuizen | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Naadloze ferritische & austenitische legeringsstalen ketel-, superheater- en warmte-uitwisselaarbuizen | Astm a213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Naadloze koolstalen en legeringen voor mechanische buizen | Astm a333 | ø1/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Naadloze en gelaste koolstalen en legeringsstalen buizen voor gebruik bij lage temperaturen | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Naadloze koudgetrokken koolstalen voedwaterverwarmeerbuis | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Productnaam | Uitvoeringsnorm | Afmeting (mm) | Staalcode / Staalklasse |

| Naadloze Staalbuizen voor Verhoogde Temperatuur | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Naadloze Staalbuizen | DIN 1629 \/ DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Naadloze Staalbuizen | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Naadloze Staalbuizen voor Structuurdoeleinden | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| Bs | |||

| Productnaam | Uitvoeringsnorm | Afmeting (mm) | Staalcode / Staalklasse |

| Naadloze Staalbuizen voor Machineconstructies | BS 970 | ø10~762x WT1.0~120 | Koolstofstaal |

| Naadloze Staalbuizen voor Ketels en Warmtewisselaars | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Concurrerend voordeel:

1. Lichte gewicht.

De parameter is 1/5 van het vierkante staal, dus heeft het een betere gewichtsprestatie en lichtprestatie, lichter dan vierkant staal, en zijn gewicht is slechts 1/5 van vierkant staal.

2. Corrosie- en hoge temperatuur weerstand.

Het heeft goede corrosie-weerstand en hoge temperatuur weerstand, beter dan vierkant staal, A333 corrosie-weerstand tegen zuur, base, zout en atmosferische omgeving corrosie, hoge temperatuur weerstand, goed impactweerstand en vermoeiingsweerstand, heeft geen regelmatige onderhoud nodig, effectieve dienstleven kan meer dan 15 jaar duren.

3, geen deformatie en antistatisch.

Het heeft goede antistatische eigenschappen, beter dan gewone stalen buizen, naadloze buizen hebben hoge elasticiteit, herbruikbaar in mechanische apparatuur, geen geheugen, geen deformatie, en antistatisch, naadloze buizen hebben uitstekende mechanische eigenschappen, gemakkelijk te bewerken, etc.

Ons vriendelijke team hoort graag van u!