| Plaats van oorsprong: | Shandong, China |

| Merknaam: | $560-600/TON |

| Modelnummer: | A106/A53GRB API5L/Q195,Q235,Q275,Q355,Q345,SAE1010/1020,1045,enz. |

| Certificering: | API, CE, Bsi, RoHS, SNI, BIS, tisi, KS, JIS, GS, ISO9001 |

| Minimale bestelhoeveelheid: | 1ton |

| Prijs: | $560/TON |

| Verpakkingsdetails: | Exportverpakkingsstandaard (In bundels, Nylon tassen, houten kisten of zoals vereist) |

| Levertijd: | 3-7 dagen |

| Betaalvoorwaarden: | FOB 30%T/T, 70% voor verzending |

| CIF 30% voorschot en de rest te betalen voor verzending | |

| of Onherroepelijk 100% L/C tegen zicht | |

| Leveringscapaciteit: | 10000 Ton per Maand |

Beschrijving:

Een gegalvaniseerde staalbuis wordt onderverdeeld in een warmtegalvaniseerde staalbuis en een koudegalvaniseerde staalbuis

Hot dip galvaniseerde buis

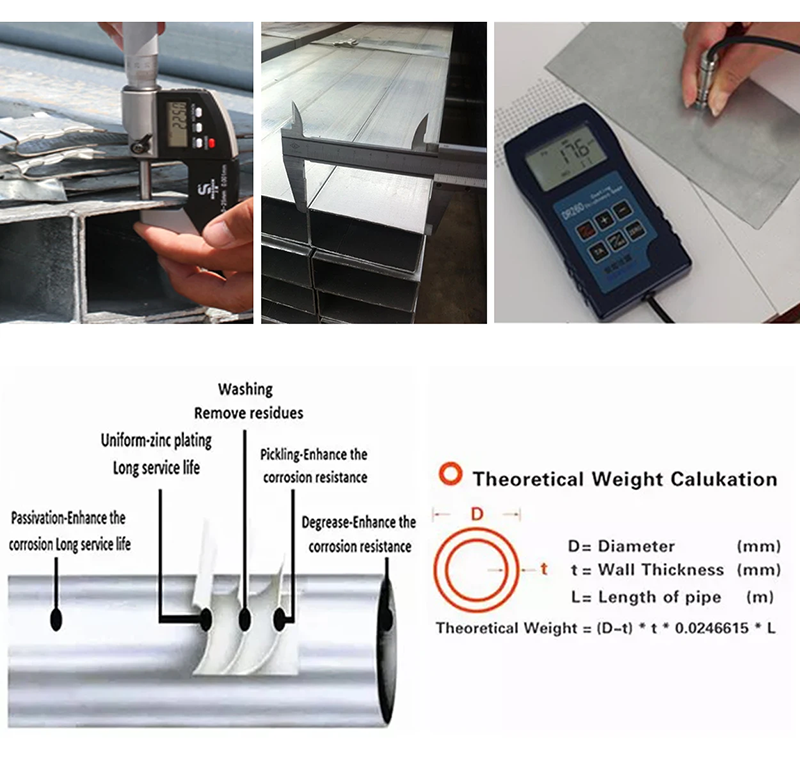

Het vloeibare metaal reageert met een ijzermatrix om een legeringslaag te vormen, waardoor de basis en de galvaniselaag worden verbonden. Warmtegalvaniseren bestaat eruit om eerst de stalen buis in te zuurten, om het ijzeroxid op het oppervlak van de stalen buis te verwijderen. Na het zuurten wordt het gewassen met een ammoniumchloride- of zincchloride-oplossing of een gemengde wateroplossing van ammoniumchloride en zincchloride, en daarna ingevoerd in de warmtegalvanisatiebak. Warmtegalvaniseren heeft de voordelen van een uniforme galvanisatie, sterke hechting en een lange serviceleven. De meeste noordelijke processen gebruiken galvaniseerde linten om direct de zinc te wikkelen.

Koud gegalvaniseerde buis

Koude galvanisering is elektrogalvanisering. De hoeveelheid galvanisering is zeer klein, slechts 10-50g/m2, en de corrosiebestendigheid is veel slechter dan die van warm gedoopte galvaniseringsbuizen. Reguliere galvaniseringsbuisfabrikanten zorgen ervoor dat de kwaliteit wordt gegarandeerd, de meeste gebruiken geen elektrogalvanisatie (koud galvaniseren). Alleen kleine bedrijven met kleine apparatuur en oude apparatuur gebruiken elektrisch galvaniseerd staal, natuurlijk zijn hun prijzen relatief goedkoper. In nieuw gebouwde huizen is het gebruik van koud geëlektrificeerde stalen buizen als watervoorzieningsbuizen verboden.

Verschil tussen hot-dip galvaniseren en koud galvaniseren

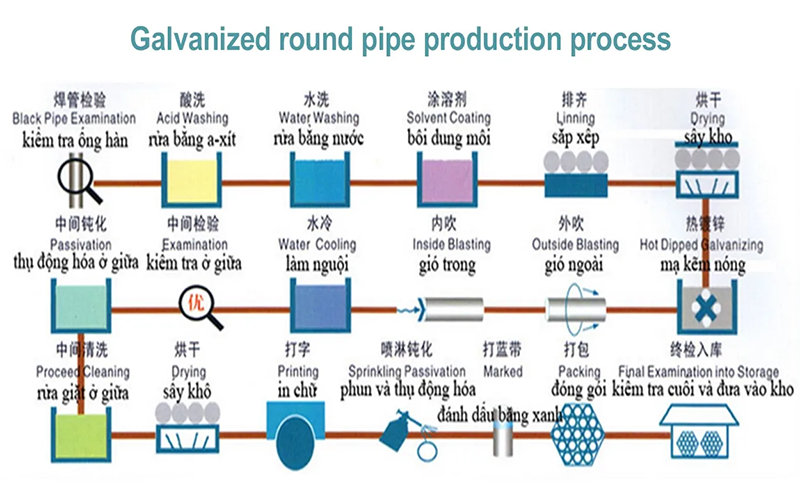

Hot-dip galvaniseringsproces:

Arbeidsstuk ontsmeren → wassen → descalen → wassen → drogen oplossen in solvent voorbewerking preheated hot dip galvaniseren → afkoelen → afwerken → spoelen → drogen → passivering test

Koud-galvaniseringsproces:

Chemische ontvetting → wassen → heet water elektrolyseontvetting → wassen → wassen → sterk corrosief galvaniseren van ijzerlegeringen → wassen → wassen → licht → → wassen → drogen passiveren

Voordelen van galvaniseerde buizen zijn onder andere:

Ten eerste kan de oppervlakte van een galvaniseerde buis na hot dip galvaniseren worden beschermd, en binnenin de holte van de buis of enige andere coating is het moeilijk om in de hoek te komen, terwijl het zink gemakkelijk de bovenkant kan bedekken, waardoor de hele galvaniseerde buis wordt beschermd.

Tweede, na het galvaniseren van een buis wordt de weervastheid en slijtage weerstand erg goed, omdat de hardheid van de zinklaag groter is dan de hardheid van staal, waardoor de weervastheid en slijtage weerstand na het warm-galvaniseren erg goed is. Bovendien is het grootste voordeel van galvaniseren dat de zinklaag in hoeken relatief dikker is en goede taatheid en slijtage weerstand heeft, terwijl andere coatingsoorten vaak in deze hoeken dunner zijn, wat de constructie moeilijker maakt en kwetsbaarder voor beschadiging.

Specificaties:

| l Omschrijving | l Galvaniseerde geweldbuizen | |

| l Staalkwaliteit | l Astm a53 Gr.B / ASTM A106 | |

| l Standaard | l ASTM A106/A106M;ASTM A53/A53M;API 5L;GB/T 8163-2008;GB/T 8162-2008;BS1387, BS1139,EN39, EN1139, ASTM A53, JIS G3444 | |

| l Materiaal | l A106 Klas A,A106 Klas B,A106 Klas C,A53 Klas A,A53 Klas B,API 5L Klas B,10#,20#,45# | |

| l Oppervlakte | l Warm-galvaniseren; Elektro-galvaniseren; Klantgespecificeerde methode | |

| l Type | l 1. Vooraf geverfd (zink: 60-120G/M2)l 2. Warm-gedrenkte galvanisatie (zink: 120-500G/M2)l 3. Koud-gedrenkte galvanisatie (zink: 10-50G/M2) | |

| l Maat | l Wanddikte | l 1-22mm |

| Buitendiameter | 21.3mm-610mm | |

| l Leveringstijd | l Snelle levering of zoals de bestelgrootte. | |

| l Verpakking | l Standaard exportzeewaardige verpakking, of zoals vereist. | |

| l Toepassing | vervoer van vloeistoffen; structurele ondersteuning; HVAC; olie- en gasindustrie; industriële apparatuur | |

| contact | als u vragen heeft, aarzel dan niet om mij te contacteren. | |

| containergrootte | 20ft GP: 5898mm(Lengte)x2352mm(Breedte)x2393mm(Hoogte) 24-26CBMl l 40ft GP: 12032mm(Lengte)x2352mm(Breedte)x2393mm(Hoogte) 54CBMl l 40ft HC: 12032mm(Lengte)x2352mm(Breedte)x2698mm(Hoogte) 68CBM |

|

Een snelle detail:

1.gi buis, Hot Dip Galvanized Round Steel Pipe, Galvanized Steel Pipe Galvanized Tube, geweldde gi staalbuis, gi staaltube

2.Hot dipped galvanized steel round pipe (HDG) wordt wereldwijd gebruikt in verschillende industrieën en bouwgebieden.

Koud gegalvaniseerde buizen zijn elektrogalvaniseerd, met een zeer kleine hoeveelheid galvanisatie, slechts 10-50g/m2, waardoor hun corrosieweerstand sterk verschilt van hot gegalvaniseerde buizen.

Het kan worden gebruikt in de bouw, machinerie, steenkoolmijnbouw, chemische industrie, elektriciteitssector, spoorwegvoertuigen, automobielsector, snelwegen, bruggen, containers, sportfaciliteiten, landbouwmachinerie, olie-industrie, verkenningsmachinerie en andere fabricage-industrieën.

| Chemische eigenschappen % | |||||||||

| Klasse A | |||||||||

| C | Mn | P | S | Ja, ja. | Cr | Cu | Mo | Ik | V |

| 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Klasse B | |||||||||

| C | Mn | P | S | Ja, ja. | Cr | Cu | Mo | Ik | V |

| 0.3 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Klasse C | |||||||||

| C | Mn | P | S | Ja, ja. | Cr | Cu | Mo | Ik | V |

| 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Mechanische eigenschappen | |||

| Klasse A | Klasse B | Klasse C | |

| Treksterkte | 330 | 415 | 485 |

| Vloei Sterkte | 205 | 240 | 275 |

Omschrijving:

Gegalvaniseerd geweld pipe verwijst naar een type staalbuis die is bekleed met een laag zink door middel van een proces genaamd galvanisatie.

Het galvaniseringsproces bestaat uit het dompelen van de staalbuis in een bad van vloeibaar zink, wat een beschermende laag op het oppervlak van de buis vormt.

Het doel van het galvaniseren van gewelde buizen is om corrosiebestandheid te bieden en de levensduur van de buis te verlengen. De zinkbekleding fungeert als een barrière tussen het staal en de omgeving, waardoor de buis wordt beschermd tegen roest en andere vormen van corrosie.

Dit maakt gegalvaniseerde gewelde buizen geschikt voor verschillende toepassingen, vooral in sectoren waar blootstelling aan vocht of corrosieve stoffen normaal is.

Enkele belangrijke voordelen van gelaste galvaniseerde buizen zijn:

1. Corrosiebestendigheid: De zinklaag biedt uitstekende corrosiebestendigheid, waardoor galvaniseerde buizen geschikt zijn voor gebruik in de openlucht en ondergronds.

2. Duurzaamheid: De combinatie van staal en zinklaag verhoogt de sterkte en duurzaamheid van de buis, wat het mogelijk maakt om

strengere omstandigheden en zware gebruik te doorstaan.

3. Kosteneffectief: Gelaste galvaniseerde buizen zijn in het algemeen goedkoper dan andere corrosiebestendige alternatieven, waardoor ze een kosteneffectieve keuze vormen voor verschillende projecten.

4. Eenvoudige installatie: Galvaniseerde gelaste buizen zijn relatief eenvoudig te installeren vanwege hun gestandaardiseerde maten en compatibiliteit

met veelgebruikte aansluitingen en verbindingen.

5. Veelzijdigheid: Galvaniseerde gelaste buizen zijn beschikbaar in verschillende maten en diktes, waardoor ze geschikt zijn voor een breed scala aan toepassingen, inclusief sanitaire installaties, bouw, landbouw en industriële projecten.

Het is belangrijk om te noteren dat gegalvaniseerde gelaste buizen beperkingen hebben. Met de tijd kan de zinklaag afbrokkelen of eraf dragen,

vooral in zeer corrosieve omgevingen. Daarom zijn regelmatige inspecties en onderhoud nodig om de voortdurende bescherming van de buis te waarborgen.

Daarnaast is het belangrijk om bij het werken met gegalvaniseerde gelaste buizen de juiste veiligheidsmaatregelen te nemen, zoals het gebruik van

geschikte persoonlijke beschermingsmiddelen en het zorgen voor voldoende ventilatie, omdat het galvaniseringsproces dampen kan vrijlaten die schadelijk kunnen zijn als ze worden ingeademd.

Toepassingen:

bouw, machinerie, steenkoolmijnbouw, chemische industrie, elektriciteitsproductie, spoorwegvoertuigen, automobieler, snelwegen, bruggen, containers, sportfaciliteiten, landbouwmachinerie, olie-machinerie, verkenningsmachinerie en andere fabricage-industrieën.

Specificaties:

| Gegalvaniseerde Ronde Staalbuis | |||||||||

| Norm: API 5L, API 5CT, ASTM A53, ASTM A500, GB9711.1 Toepassing: Te gebruiken voor het vervoeren van gas, water en petroleum voor olie- en aardgasindustrieën en gebruik voor het doel van structuurstaal buizen Hoofd Staalbuis Kwaliteit: GR.A, GR.B, GR.C, Q195, Q235B, Q345B enzovoort. |

|||||||||

| Inch | OD(mm) | Standaard Wanddikte | |||||||

| SCH 10WT (mm) | SCH 20WT (mm) | SCH 40WT (mm) | SCH 60WT (mm) | SCH 80WT (mm) | SCH 100WT (mm) | SCH 160WT (mm) | XXS (mm) | ||

| 1/4” | 13.7 | 2.24 | 3.02 | ||||||

| 3/8” | 17.1 | 2.31 | 3.2 | ||||||

| 1/2” | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.5 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.7 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.7 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

| 30" | 762 | 7.92 | 12.7 | ||||||

| 32" | 813 | 7.92 | 12.7 | 17.48 | |||||

| 34" | 863 | 7.92 | 12.7 | 17.48 | |||||

| 36" | 914 | 7.92 | 12.7 | 19.05 | |||||

| 38" | 965 | ||||||||

| 40" | 1016 | ||||||||

| 42" | 1066 | ||||||||

| 44" | 1117 | ||||||||

| 46" | 1168 | ||||||||

| 48" | 1219 | ||||||||

Concurrerend voordeel:

Wij bieden scherpe prijzen en betrouwbare leveringstijden voor het aanbieden van naadloze stalen buizen, niet alleen voor grote klanten, maar we accepteren ook op maat gemaakte ontwerpen, specificaties en verpakkingseisen van klanten.

Ons vriendelijke team hoort graag van u!