| Place of Origin: | Shandong, China |

| Brand Name: | Changshengda(CSD) |

| Model Number: | Q195/Q235/Q345 SS400 |

| Certification: | API, CE, GS, ISO9001 |

| Minimum Order Quantity: | 20 tons |

| Price: | 545USD/TON-680USD/TON |

| Packaging Details: | 1.Standard Marine packing |

| 2.According to customer requirements | |

| Port: | Shanghai, Tianjin, Qingdao ports, you can specify other ports according to your needs. |

| Delivery Time: | 8-14days |

| Payment Terms: | L/C,T/T |

| Supply Ability: | 100000tons/month |

| Material: | ERW:Q235, Q345, 20#, J55, X42~65, etc. |

| LASW:Q195,Q235,Q345B,X42,X52,X60,S355JRH,S355J0H,S355J2H etc |

Description:

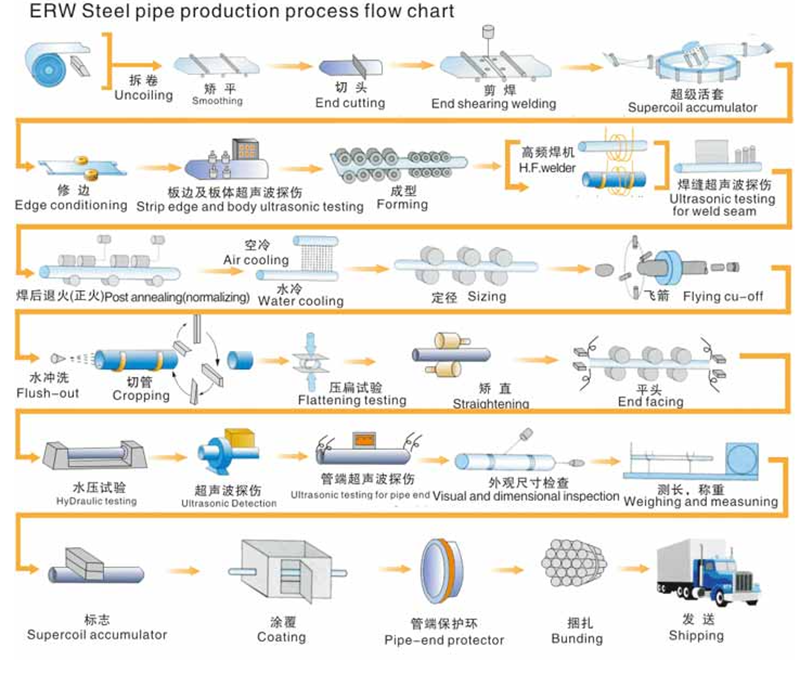

Straight seam high frequency (ERW) is divided into two forms: induction welding and contact welding according to different welding methods. It uses hot-rolled wide coils as raw materials and undergoes pre-bending, continuous forming, welding, heat treatment, sizing, straightening, cutting, etc. Compared with the spiral process, it has the advantages of shorter welds, high dimensional accuracy, uniform wall thickness, good surface quality, and high pressure resistance. However, the disadvantage is that it can only produce thin-walled pipes of small and medium diameters, and gray spots and lack of fusion are prone to occur at the welds. , Groove corrosion defects. At present, the most widely used fields are city gas, crude oil and refined oil transportation, etc.

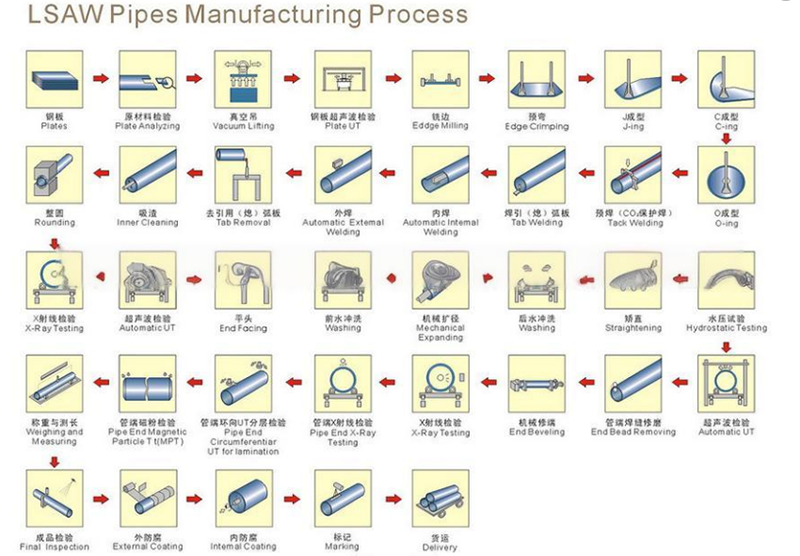

Straight seam submerged arc (LSAW) is produced by using a single medium-thick plate as raw material, pressing (rolling) the steel plate in a mold or forming machine, and using double-sided submerged arc welding and diameter expansion. Its finished product specifications range is wide, the toughness, plasticity, uniformity and density of the weld are good, and it has the advantages of large pipe diameter, thick pipe wall, high pressure resistance, low temperature resistance and strong corrosion resistance. When constructing high-strength, high-toughness, and high-quality long-distance oil and gas pipelines, most of the required steel pipes are large-diameter, thick-walled straight seam submerged arc pipes. According to API standards, in large-scale oil and gas transmission pipelines, straight-joint submerged arc is the only designated applicable pipe type when passing through Class 1 and Class 2 areas such as alpine zones, seabed, and densely populated urban areas.

According to different molding methods, it can be divided into:

UOE steel pipe: After the single steel plate is pre-bent at the edge, it undergoes processes such as U forming, O forming, internal welding, external welding, and mechanical cold expansion.

JCOE steel pipe: that is, pre-welding, forming, and cold expansion after welding according to "J-C-O-E"

HME steel pipe: formed by mandrel rolling method according to "C-C-O", welded and then cold expanded.

Specifications:

| ERW PIPE | |

| ASTM | ASTM A53 B, ASTM A178, ASTM A252 GR.2, A500, ASTM A513 |

| EN | EN 10204/10217 S235JR,S275JR,S355,S355JR,S355J2H |

| API | API 5L X42/46/52/56/60/70 |

| Carbon steel | ASTM A671,ASTM A672 |

| Alloy steel | ASTM A691 |

| OD | 1/2" -24" (21.3mm-610mm) |

| WT | 1.65mm-20mm |

| Application | Line Pipe ; OCTG (Oil Country Tubular Goods);Round Structural Pipe; Coating Pipe. |

| LSAW PIPE | |||

| Standard | ASTM 53 ;API Spec 5L;ASTM A252-89; EN10217, EN10219 | ||

| Steel Grades | API 5L: GR A, GR B, X42, X46, X56, X60, X65, X70ASTM A252 GR 1, GR 2, GR 3ASTM A53: GR A, GR B, GR C, GR DBS 4360: Grade 43, Grade 50EN: S275, S275JR, S355JRH, S355J2H |

||

| Application | Used for oil/gas/water;Transmission;Engineering;Offshore projects. | ||

| Usage | OD(mm) | WT(mm) | LENGTH(m) |

| Roller pipe | 1200-3800(47.24”-150”) | 12-120 (1/2”- 4.7”) | <=3.2 |

| for Construction(Pipe Piles) | 350-1600(14”- 63”) | 6-60 (1/4” -2.36”) | 6-12 |

| Oil &gas pipeline | 406-1524(16”- 60”) | 6-40 (1/4”-1.57”) | 8-12.1 |

| Addition to above specification, the pipes can be produced according to customer’s requirements. | |||

Quick Detail:

Description:

Low pressure fluid conveying straight seam steel pipe

Diameter: 219mm~508mm

Wall thickness: 6mm~20mm

Standard: GB/T 3091-2008

Material: L245~L690, Q235, etc.

Applications: Suitable for straight seam welded steel pipes used in the transportation of low-pressure fluids such as water, gas, air, and heating steam and other structures.

American standard straight seam welded steel pipe

Diameter: 219mm~406mm

Wall thickness :6mm~14mm

Standard: ASTM

Material: GrA GrB

Applications: Mainly used in water conservancy projects, oil and gas industry, chemical industry, electric power industry, agricultural irrigation, urban construction, etc.

Straight seam steel pipes for oil casing and oil pipes

Diameter 219mm~508mm

Wall thickness 6mm~20mm

Standard API-5CT

Material H40, J55, N80, P110

Application: Oil casing and tubing.

American standard spiral welded steel pipe

Diameter 219mm~3520mm

Wall thickness 5mm~26mm

Standard ASTM

Material Gr.A, Gr.B, Gr.C, Gr.1~Gr.11

Application: Mainly used in pile pipes for water conservancy projects, oil and gas industry, chemical industry, electric power industry, agricultural irrigation, urban construction, etc.

Straight seam pipeline steel pipes for oil and gas transportation

Diameter 219mm~508mm

Wall thickness 6mm~20mm

Standard API-5L

Material Gr.B, X42~X100

Application: Used for oil and natural gas transportation.

Competitive Advantage:

The company has selected internationally advanced technology and equipment: such as W-FF molding, solid-state high-frequency induction welding, ultrasonic flaw detection, magnetic flux leakage detection, and high-end testing instruments: such as metallographic analysis, Vickers hardness tester, impact testing machine, spectrometer Analyzers, universal testing machines and other equipment. Since its establishment, it has obtained various international certifications and honorary qualifications: such as API 5L, API5CT, ISO9002-2000 pressure pipeline production license, industrial product production license, China Petroleum and Petrochemical Membership Certificate, China Quality Product Certificate, etc. Products are exported to South America, North America, the European Union, Southeast Asia and other places. It has been well received by customers all over the world for many years.

Our friendly team would love to hear from you!