| Место происхождения: | Шаньдун, Китай |

| Название бренда: | jinzheng |

| Номер модели: | 16MnDG, 10MnDG, 09DG, 09Mn2VDG, 06Ni3MoDG, ASTM A333-Grade1, Grade3, Grade4, Grade6, Grade7, Grade8, Grade9, Grade10, Grade11 |

| Сертификация: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| Минимальное количество заказа: | 1 тонна |

| Цена: | $650/тонна |

| Подробности упаковки: | Стандарт упаковки для экспорта (В пучках, полиамидные мешки, деревянные ящики или по требованию) |

| Время доставки: | 15-20 дней |

| Условия оплаты: | FOB 30% T/T, 70% перед отправкой |

| CIF 30% предоплата, остаток должен быть оплачен до отправки | |

| или Ирревокабельный аккредитив 100% при получении документов | |

| Способность поставки: | 2000 Тонн/месяц |

Быстрая деталь:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984, бесшовная труба, Бесшовная углеродистая и легированная сталь для механических труб

Труба из низкотемпературной стали A333 широко применяется в нефтехимической, природногазовой, химической, электростанциях, отоплении и других областях. Ее применение разнообразно и гибко: в нефтяных и газовых трубопроводах, нефтехимическом оборудовании, системах кондиционирования воздуха, охладителях, парогенераторах, а также используется в машинообработке, давлениых емкостях, котельном производстве, строительной стальной конструкции, крупных объектах, выставочных центрах, подъемных механизмах, судостроении, складских полках, отделке, транспортных сооружениях, строительстве аэропортов, опорах мостов, многоуровневых гаражах, наружной рекламе, спортивном оборудовании, производстве автомобилей и других отраслях.

Химические требования

| Элемент | Состав, % | ||||||||

| Марка 1A | Марка 3 | Класс 4 | Марка 6A | Марка 7 | 8 класс | Марка 9 | Марка 10 | Марка 11 | |

| Углерод, макс | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Магний | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 макс | 0.90 макс | 0.40-1.06 | 1.15-1.50 | 0.60 Макс |

| Фосфор, макс | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Сера, макс | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Кремний | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 мин | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 макс |

| Никель | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 Макс | 35.0 -37.0 |

| Хром | - | - | 0.44-1.01 | - | - | - | - | 0.15 макс | 0.50 макс |

| Медь | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 макс | - |

| Алюминий | - | - | 0.04-0.30 | - | - | - | - | 0.06 макс | - |

| Ванадий, макс | - | - | - | - | - | - | - | 0.12 | - |

| Колумбий, макс | - | - | - | - | - | - | - | 0.05 | - |

| Молибден, макс | - | - | - | - | - | - | - | 0.05 | 0.50 макс |

| Кобальт | - | - | - | - | - | - | - | - | 0.50 макс |

Требования к растяжению

| 1 класс | Марка 3 | Класс 6 | Марка 7 | |||||

| фунт-сил на квадратный дюйм | МПа | фунт-сил на квадратный дюйм | МПа | фунт-сил на квадратный дюйм | МПа | фунт-сил на квадратный дюйм | МПа | |

| Предел прочности на растяжение, мин Предел упругости, мин | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Долгitudинальное | Transwerse | Продольная | Transwerse | Продольная | Transwerse | Продольная | Transwerse | |

| Деформация при растяжении в 2 дюйма или 50 мм, (или 40). мин, %: Основное минимальное удлинение для стен толщиной 5/16 дюйма (8 мм) и более в толщину, тесты полос. И для всех малых размеров, испытанных в полном сечении, когда стандартный круглый 2-дюймовый или 50-миллиметровый измеритель длина или пропорционально меньший размер испытательный образец с длиной измерительного участка равной 4D (4 умножить на диаметр) используется для испытаний полос, вычет для каждого 1/32 дюйма [0,8 мм] уменьшения в толщине стенки ниже 5/16 дюйма (8 мм) от базового минимального удлинения следующего процента |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| 8 класс | Марка 9 | Марка 10 | Марка 11 | |||||

| фунт-сил на квадратный дюйм | МПа | фунт-сил на квадратный дюйм | МПа | фунт-сил на квадратный дюйм | МПа | фунт-сил на квадратный дюйм | МПа | |

| Предел прочности на растяжение, мин Предел упругости, мин | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Долгitudинальное | Transwerse | Продольная | Transwerse | Продольная | Transwerse | Продольная | ||

| Деформация в 2 дюйма или 50 мм, (или 40). мин, %: Основная минимальная деформация для стен толщиной 5/16 дюйма (8 мм) и более по толщине, полосовые испытания. И для всех малых размеров, испытанных в полном сечении, когда стандартный круг 2 дюйма или 50 мм рабочей длины или пропорционально меньшего размера образца с рабочей длиной, равной 4D (4 диаметра), используется. Для полосовых испытаний, вычет за каждый 1/32 дюйма [0.8 мм] уменьшения толщины стенки ниже 5/16 дюйма (8 мм) от базового минимального удлинения следующий процент |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Описание

1. Краткое описание продукта

Труба бесшовная низкотемпературная主要用于 нефтяной, химической, природного газа и угля отраслях как сырье для производства этилена, пропилена, мочевины, синтетического аммиака, N-P-K комплексных удобрений и фармацевтической промышленности для процессов мойки, очистки, десульфуризации и обезжиривания. Также она используется в производстве криогенного оборудования, сверхнизкотемпературных складских помещений, транспортировке сверхнизкотемпературных жидкостей и трубопроводных компонентов. Международная система низкотемпературных бесшовных стальных труб представлена стандартом ASTM A333/A333M-2011 (далее называемым американским стандартом), который применим в условиях температуры до -196℃. В настоящее время производство и приемка низкотемпературных бесшовных стальных труб во всем мире в основном осуществляется по американскому стандарту, и внутренний дизайн также ссылается на этот стандарт. Среди девяти марок американского стандарта криогенных труб, Gr.6 широко применяется в нефтехимической промышленности и транспортировке жидкостей в условиях низких температур и холодных районов, а годовой спрос на них на американском и европейском рынках превышает 20,000 т.

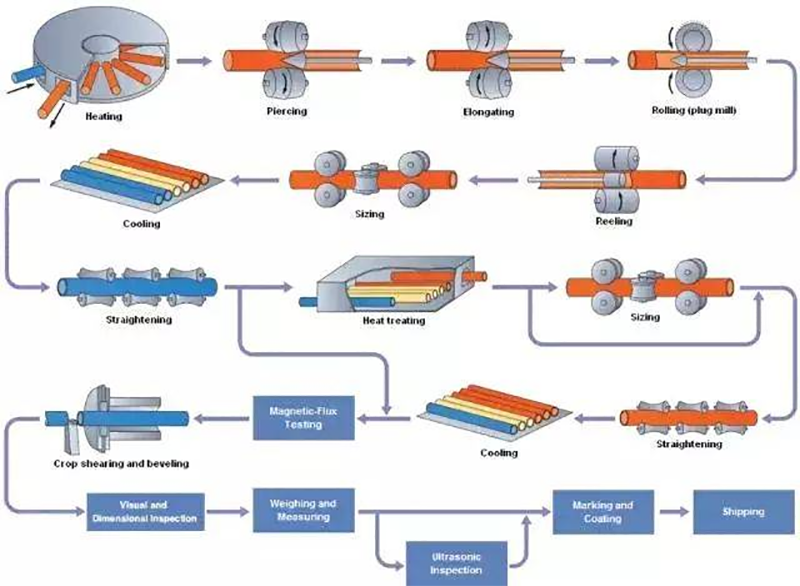

2. Процесс производства

Производство - Трубы изготавливаются методом сварки, который может быть бесшовным или не добавлять наполнительный металл. Уровень 4 должен изготавливаться по бесшовной технологии.

Термическая обработка

Все бесшовные и сварные трубы должны подвергаться термической обработке для контроля их микроструктуры одним из следующих методов.

Равномерно нагреваются до температуры не менее 1500F (815℃) для положительной термообработки, а затем охлаждаются на воздухе или в охлаждающей камере печи с контролируемым содержанием кислорода в воздухе.

Стальная труба нормализуется и повторно нагревается до подходящей температуры отпуска, определяемой сталелитейным заводом. Хороший контроль повторного нагрева трубы обеспечивает контроль температуры горячей обработки в пределах диапазона горячей формовки от 1550 до 1750F (845-945 °C), а затем охлаждается в печи с контролируемым газом кислорода с начальной температурой не менее 1550F (845 °C). Этот метод применим только для бесшовных процессов.

Его обрабатывают и повторно нагревают до подходящей температуры отпуска, определенной заводом.

При указании в заказе образец должен быть вырезан из испытательного блока заданной толщины, который берется из стальной трубы тепловой закалки, и должен быть подвергнут снятию напряжения. Испытательный блок должен постепенно нагреваться до указанной температуры, увлажняться при этой температуре в течение указанного времени, а затем охлаждаться до температуры, не превышающей 600F (315 ° C). Испытательный блок труб из стали марки 8 должен быть охлажден на воздухе или водой с минимальной скоростью охлаждения 300F/ (165℃/ч) до температуры, не превышающей 600F (315℃).

3. Основной бренд или марка стали продукта

ASTM A333-Grade1, Grade4, Grade6, Grade7, Grade9, Grade10

ASTM A334-Grade1, Grade6, Grade7, Grade9

API 5CT80, L80-1, L803Cr, P110

4. Нормативные стандарты продукции

GSTM 8333, GSTM 8334, API SPEC 5CT (9th)

5. Особенности продукта

Компания устойчива к низким температурам и не содержит сосудистых образований. Использование стали высокой чистоты с низким содержанием серы и фосфора, а также проведение кальцификационной обработки может эффективно снижать хрупкость стали при низких температурах и повышать ударную вязкость продукции. У компании есть бак охлаждения на 0 "-100°C, который позволяет проводить пакетные низкотемпературные ударные испытания для обеспечения качества и стабильности продукции.

6. Условия использования продукта

Криогенные трубы A333 и A334 используются для труб криогенных сосудов класса -45 до -195°C, а также для труб криогенных теплообменников. Они также могут использоваться для транспортировки жидкости в условиях низких температур. Надежная обсадная колонна API5CT主要用于 extremely холодных районах для бурения скважин. Стальная труба может использоваться при экстремально низких температурах, но также обладает высокой прочностью, коррозионной стойкостью, хорошими технологическими свойствами и свариваемостью. Эти характеристики делают криогенную трубу A333GR.6 широко используемой в нефтяной, газовой, химической и других промышленных отраслях.

7. Диапазон спецификаций продукта

Внешний диаметр: 16 мм ~ 323,9 мм; Толщина стенки: 2,0 мм ~ 40,0 мм

Применение:

Широко применяется в нефтехимической, газовой, химической, электростанционной отраслях, а также в системах отопления и других сферах. Широкий спектр применения, гибкость. Используется в трубопроводах для транспортировки нефти и природного газа, в нефтехимическом оборудовании, системах кондиционирования воздуха, охладителях, парогенераторах, а также в механической обработке, производстве сосудов под давлением, котельном оборудовании, строительных стальных конструкциях, крупных помещениях, выставочных центрах, подъемном оборудовании, судостроении, складских полках, отделке, транспортных средствах, аэропортах, мостовых опорах, горнодобывающей промышленности, многоуровневых гаражах, наружной рекламе, фитнес-оборудовании, производстве автомобилей и других отраслях.

Спецификации:

Стандарты бесшовной стальной трубы

| API SPEC 5L | |||

| Название продукта | Исполнительный стандарт | Размер (мм) | Код стали / Марка стали |

| Трубопроводы линейные | Api 5l | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| Название продукта | Исполнительный стандарт | Размер (мм) | Код стали / Марка стали |

| Обрамление | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Рукав | API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Название продукта | Исполнительный стандарт | Размер (мм) | Код стали / Марка стали |

| Черные и оцинкованные горячим методом бесшовные стальные трубы | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Бесшовные углеродистые стальные трубы для работы при высоких температурах | Astm a106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Бесшовные холоднодеформированные низкоуглеродистые стальные трубки для теплообменников и конденсаторов | ASTM A179 | ø10.3~426x WT1.0~36 | Сталь с низким содержанием углерода |

| Бесшовные углеродистые стальные трубки для котлов высокого давления | ASTM A192 | ø10.3~426 x WT1.0~36 | Сталь с низким содержанием углерода |

| Бесшовные холоднотянутые трубки из легированной стали для теплообменников и конденсаторов | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Бесшовные трубы из средней углеродистой стали для котлов и перегревателей | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Бесшовные ферритовые и аустенитовые легированные стальные трубы для котлов, перегревателей и теплообменников | Astm a213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Бесшовная углеродистая сталь и легированная сталь для механических труб | ASTM A333 | ø1/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Бесшовные и сварные углеродистые стальные трубы и легированные стальные трубы для использования при низких температурах | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Бесшовные холоднотянутые углеродистые стальные трубы подогревателя питательной воды | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Название продукта | Исполнительный стандарт | Размер (мм) | Код стали / Марка стали |

| Бесшовные стальные трубы для высоких температур | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Seamless стальные трубы | DIN 1629 / DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Seamless стальные трубы | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Гладкие стальные трубы для конструкционных целей | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| Бс. | |||

| Название продукта | Исполнительный стандарт | Размер (мм) | Код стали / Марка стали |

| Гладкие стальные трубы для машинной конструкции | BS 970 | ø10~762x WT1.0~120 | Углеродистая сталь |

| Гладкие стальные трубы для котлов и теплообменников | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Конкурентное преимущество:

1. Легкий вес.

Параметр составляет 1/5 от квадратной стали, поэтому у него лучше показатели веса и легкости, он легче, чем квадратная сталь, и его вес составляет только 1/5 от веса квадратной стали.

2. Сопротивление коррозии и высоким температурам.

У него хорошая устойчивость к коррозии и высоким температурам, лучше, чем у квадратной стали. A333 сопротивляется коррозии в кислой, щелочной, солевой среде и атмосферных условиях, устойчив к высоким температурам, обладает хорошим сопротивлением удару и усталости, не требует регулярного обслуживания, эффективный срок службы может достигать более 15 лет.

3, нет деформации и антистатические свойства.

У него хорошие антистатические свойства, лучше, чем у обычных стальных труб. Бесшовные трубы имеют высокую эластичность, могут использоваться повторно в механическом оборудовании, без памяти, без деформации и антистатические. Бесшовные трубы обладают отличными механическими свойствами, легко обрабатываются и т.д.

Наша дружелюбная команда будет рада услышать от вас!