| Place of Origin: | Liaocheng, China |

| Brand Name: | Jinzheng |

| Model Number: | ASTM A312, ASTM A213, etc |

| Certification: | CE, BIS, JIS, GS, ISO9001 |

| Minimum Order Quantity: | 1 ton |

| Price: | 2000-6000 USD per ton |

| Packaging Details: | INTERNATIONAL STANDARD PACKING |

| Delivery Time: | |

| Payment Terms: | T/T, Lc at sight |

| Supply Ability: | 3000 tons per month |

Quick Detail:

Stainless steel seamless pipes are a remarkable innovation in the field of piping solutions. With their exceptional characteristics and wide-ranging applications, they have become an indispensable choice for various industries. Unlike ordinary seamless pipes, stainless steel seamless pipes offer a host of advantages that set them apart.

Description:

Unmatched Characteristics:

Stainless steel seamless pipes are renowned for their exceptional corrosion resistance, making them ideal for applications in demanding environments. They exhibit remarkable strength, durability, and high-temperature resistance, ensuring reliable performance even under extreme conditions. Additionally, their smooth internal surface minimizes friction, facilitating the efficient flow of fluids or gases.

Versatile Applications:

The versatility of stainless steel seamless pipes makes them a preferred choice across diverse industries. Their corrosion resistance makes them suitable for applications in chemical processing plants, oil and gas refineries, and marine environments. They are widely used in the construction of infrastructure, such as bridges and buildings, as well as in the automotive, aerospace, and pharmaceutical industries. Furthermore, stainless steel seamless pipes find extensive use in the food and beverage industry, ensuring the integrity and safety of processing systems.

Common Specifications and Manufacturing Processes:

Stainless steel seamless pipes are available in a wide range of specifications to meet various requirements. Commonly used specifications include different grades of stainless steel, such as 304, 316, 321, and 904L, with varying sizes and wall thicknesses. These pipes are manufactured through a meticulous process that involves hot extrusion or piercing of a solid billet. This method ensures the absence of seams, resulting in a seamless pipe with uniform thickness and excellent structural integrity.

Stringent Testing and Quality Assurance:

To ensure the highest quality standards, stainless steel seamless pipes undergo rigorous testing procedures. Common testing items include dimensional inspection, mechanical properties evaluation, chemical composition analysis, and non-destructive testing. These tests guarantee that the pipes meet or exceed industry specifications, providing customers with reliable and safe products.

Applications of ASTM-Compliant Stainless Steel Seamless Pipes:

Our manufacturing capabilities encompass ASTM A312-compliant austenitic stainless steel pipes, designed to excel in demanding environments. These pipes are widely utilized in industries such as chemical processing, oil and gas, pharmaceuticals, and food processing. We can also manufacture stainless steel pipes compliant with ASTM A213 standards, tailored specifically for heat exchanger applications. These pipes, available in both ferritic and austenitic grades, are engineered to meet the stringent requirements of heat transfer systems in industries such as power generation, chemical processing, and HVAC. Our ASTM A213-compliant stainless steel pipes provide exceptional thermal conductivity, corrosion resistance, and durability, ensuring optimal performance and longevity in heat exchange applications. In addition to austenitic and ferritic stainless steel pipes, we specialize in the production of duplex stainless steel seamless pipes, known for their exceptional strength, corrosion resistance, and versatility. Our duplex stainless steel pipes, meeting ASTM A790 and ASTM A789 standards, find extensive use in industries requiring superior resistance to corrosion, such as offshore oil and gas exploration, chemical processing, and desalination plants. These pipes offer a unique combination of high strength and excellent corrosion resistance, making them the preferred choice for challenging and aggressive environments.

Specifications:

| Product Name | Executive Standard | Dimension | Steel Code / Steel Grade |

| Seamless Austenitic Stainless Steel Pipes | ASTM A312/A312M, ASME SA312/SA312M | OD: 1/4"~20" |

TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| WT: SCH5S~SCH80S | |||

| Seamless Austenitic Stainless Steel Tubing for General Service |

ASTM A269, ASME SA269 | OD: 6.0~50.8mm | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| Seamless Austenitic Alloy-Steel Boiler, Super Heater and Heat-Exchanger Tubes |

ASTM A213/A213M, ASME SA213/SA213M | OD: 6.0~50.8mm | TP304, TP304L, TP304H, TP310, TP310S, TP316, TP316L, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H |

| WT: 0.8~10.0mm | |||

| Seamless Duplex Stainless Steel Tubing for General Service |

ASTM A789 / A789M | OD: 19.0~60.5mm | S31803, S32205, S32750 |

| WT: 1.2~5.0mm | |||

| Seamless Duplex Stainless Steel Pipes | ASTM A790 / A790M | OD: 3/4"~10" | S31803, S32205, S32750 |

| WT: SCH5S~SCH80S | |||

| Seamless Stainless Steel Mechanical Tubing | ASTM A511 | OD: 6.0~50.8mm | MT304, MT304L, MT304H, MT310, MT310S, MT316, MT316L, MT317, MT317L, MT321, MT321H, MT347 |

| WT: 1.8~10.0mm | |||

| Seamless Stainless Steel Tubes for Pressure Purposes |

EN 10216, DIN 17456, 17458 | OD: 6.0~530.0mm | 1.4301, 1.4307, 1.4541, 1.4401, 1.4404, 1.4571, 1.4878, 1.4432, 1.4462 |

| WT: 0.8~34.0mm |

Competitive Advantage:

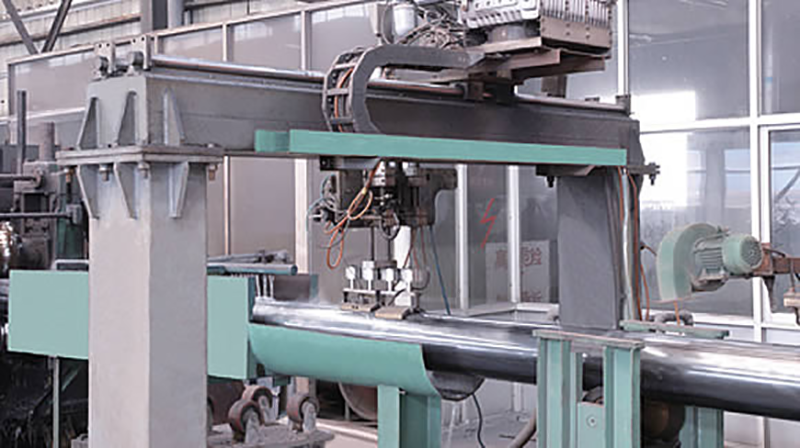

We boast a significant competitive edge in the industry, primarily attributed to our large-scale production capacity, extensive inventory, diverse production lines, and substantial investments in environmental protection.

Large Production Scale: With a robust and expansive production scale, we have the capability to meet the demands of diverse markets and clients. Our large-scale operations ensure timely delivery and consistent supply, fostering strong partnerships with our customers.

Extensive Inventory: Our substantial inventory is a testament to our commitment to meeting customer needs promptly. This allows us to respond swiftly to orders and adapt to fluctuating market demands, enhancing our reputation for reliability and customer satisfaction.

Diverse Production Lines: Our rich array of production lines enables us to manufacture a wide range of stainless steel seamless pipes, catering to various specifications and industry requirements. This versatility positions us as a one-stop solution provider for our clients, offering them a comprehensive selection of high-quality products.

Environmental Protection Investment: Recognizing the importance of sustainability, we have significantly increased our investments in environmental protection measures. By implementing eco-friendly technologies and sustainable practices throughout our production processes, we strive to minimize our environmental footprint and contribute to a greener, more responsible industry.

Our friendly team would love to hear from you!