| Ҷойи воридшавӣ: | Шандонг, Ҷунгитуи |

| Номи бренд: | ҷинжинг |

| Шомораи модел: | 16MnDG, 10MnDG, 09DG, 09Mn2VDG, 06Ni3MoDG, ASTM A333-Grade1, Grade3, Grade4, Grade6, Grade7, Grade8, Grade9, Grade10, Grade11 |

| Сертификат: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| Сабоки замини фаровӣ: | 1 тон |

| Нарх: | $650/тонна |

| Тафсилоти пакетbandi: | Стандарт упаковки для экспорта (В пучках, нейлоновые мішоки, деревянные ящики или по требованию) |

| Вақти тахлифи: | 15-20 кун |

| Шартҳои пулпурдани: | FOB 30%T/Т,70% пеш арзиши |

| CIF 30% аванс ва баланс дар суроғи арзиши шипмент | |

| ё немудори 100% L/Ц дар интизом | |

| Қобилияти таmin кунандагӣ: | 2000 Тонна/Тоннҳо дар маҳ |

Ҷозиёҳои хурд:

16MnDG,10MnDG,06Ni3MoDG,GB/Т6479,GB/Т18984,тубинг без швов, Безшовный углеродистый и сплав стали для механических труб

Лаваҳи температури пайдошти сармург (A333) дар бисмургии маъмура дар садоҳои шимия, гази табиъӣ, шимия, барқ, ғармкунӣ ва дигар садоҳо истифода мешавад. Феълпазирӣши ҳамчунин муфид аст, дар лаваҳи тарафзаниги газ ва намаки табиъӣ, ташкили шимия, системаи климатизасии хонагӣ, лаваҳҳои тарафзаниги системаяд, сухандозҳо, парсозҳо, ва ҳамچунин дар зербастии механикӣ, сосудҳои фишанда, созми кӯб, сактсозӣ, марказҳои бузург, центрҳои нümайиш, таксимоти баромад, судоборӣ, захираи тарафзаниги, ташвир, транспортӣ ташвир, сотобондии аэропорт, пӯшиш, онгошти додами, гаражи салосалӣ, рекламаи берунӣ, тадбирёфтаи фитнес, ва сотобории рӯҳорои транспортӣ ва дигар саноатҳо истифода мешавад.

Талабҳои шимия

| Унсур | Тарکиб,% | ||||||||

| Дарجة 1A | Дарجة 3 | Дарجة 4 | Дарجة 6A | Дарجة 7 | Дарجة 8 | Дарجة 9 | Синф 10 | Синф 11 | |

| Углерод, макс | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Манган | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 макс | 0.90 макс | 0.40-1.06 | 1.15-1.50 | 0.60 макс |

| Фосфор, макс | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Сульфур, макс | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Силикон | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 мин | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 макс |

| Никел | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 макс | 35.0 -37.0 |

| Хром | - | - | 0.44-1.01 | - | - | - | - | 0.15 макс | 0.50 максимум |

| Маса | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 макс | - |

| Алуминий | - | - | 0.04-0.30 | - | - | - | - | 0.06 макс | - |

| Ванадий, макс | - | - | - | - | - | - | - | 0.12 | - |

| Колумбий, макс | - | - | - | - | - | - | - | 0.05 | - |

| Молибден, макс | - | - | - | - | - | - | - | 0.05 | 0.50 максимум |

| Кобальт | - | - | - | - | - | - | - | - | 0.50 максимум |

Талабҳои кушандагӣ

| Сотиш 1 | Дарجة 3 | Сотиш 6 | Дарجة 7 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Муқовими дарaja, минДастурӣ дарaja, мин | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Узунӣ | Тарозӣ | Равеши хориҷӣ | Тарозӣ | Равеши хориҷӣ | Тарозӣ | Равеши хориҷӣ | Тарозӣ | |

| Диҳиш узуншавӣ дар 2 инч ё 50мм, (ё 40). мин, %: Асасӣ диҳиш узуншавӣ барои дарвазахо 5/16 инч (8 мм) ва бистар аст масофи, санчахтҳои полоса ва барои ҳамаи чӣракӣ сизмаҳои мутаалиф ба таван рӯйхаткунӣ шудааст мағьори донгории 2 инчи ё 50 мм масофи улчоби кучактар аз ин аст санчахтҳои испити барои улчобкунӣ ки масофиаш баробар бо 4D (чарobarи диаметр) аст истефода мешавад. Барои санчахтҳои полоса, тахфиф барои ҳар 1/32 инчи [0.8 мм] камшудаи масофи дар зер 5/16 инчи (8 мм) аз маҳдудияти минимали кушодагӣ базнависи мешавад аз дар баробар фиصلӣ |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| Дарجة 8 | Дарجة 9 | Синф 10 | Синф 11 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Муқовими дарaja, минДастурӣ дарaja, мин | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Узунӣ | Тарозӣ | Равеши хориҷӣ | Тарозӣ | Равеши хориҷӣ | Тарозӣ | Равеши хориҷӣ | ||

| Дарозӣ дар 2 инч ё 50мм, (ё 40). мин, %:Асосӣ дарозии камина барои дарвазҳои 5/16 инч (8 мм) ва бистар дар намуд, санҷишҳои шахт. ва барои хамаи аз CascadeTypeҳои кучак санҷидه шуда секшни пуркабути. Когذар рунди стандартӣ 2 инч ё 50мм гаҷ утӯлӣ ё андаزагирӣ кучактар аз инч 16/5 ё 8мм бо утӯлӣ баравори 4D (4 маротибайе диаметр) истефода мешавад барои санҷишҳои шахт, тағйир додани ҳар 1/32 инч [0.8 мм] камшидани намуди дарваза зеринч 16/5 (8мм) аз дарозии асосии камина пурсентум |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Тавсиф

1. Муқовиати кисои продукт

Лавҳи сард бе-жудаи сталӣ пайп асосан дар нефть, шимия, гази табиъӣ ва уголь як чанд хамчун этелен, пропилен, уреа, синтетик аммиак, ҳамлакии N-P-K ва саноати даромади дарозӣ шуид, пуршудани, дарозишавии сульфур ва дарозишавии жир дар таҷрибаҳои истифода мешавад, ваҳам дар сазоандагии ташкили сард, анбари сард ба фарқи сард, транспортии гази сард лавҳа ва компонентҳои пайп. Дастори дунёи системасард бе-жудаи сталӣ пайп аз ASTM A333/A333M-2011 (пеш аз ин ба вазн Америкаи стандарт нисбат додан мешавад), ки ба мohити сард та -196℃ мободаст. Халиқоти истифода ва пахши пайпҳои сард бе-жуда дар дунё бештар аз стандарди Америка истифода мебаранд, ва тағйироти даромади дахилӣ низ ба стандарди Америка нисбат додан мебаранд. Дар навъҳои тохиршудаи standardUserDefaultsи Америкаи пайпҳои сард, Gr.6 дар саноати нефть ва шимия ва ҳамчун ҷорӣ транспортии дар мohитҳои сард ва холок карда шуда истифода мешавад, ва талаби соли омӯзишӣ дар бозорҳои Америка ва Европа зиёд аз 20,000 тон мебошад.

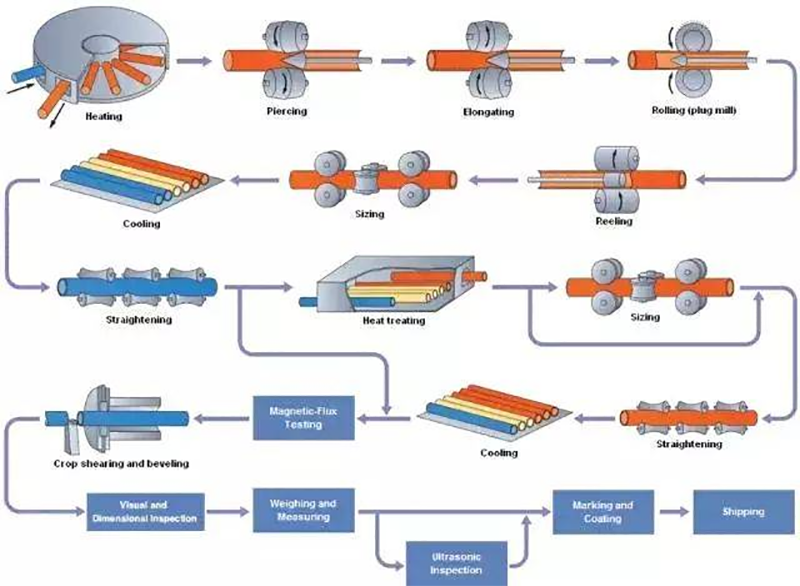

2. Процесси таъминот

Таъминот - Ластонҳо барои таъминот дар процессҳои чаркашӣ созида мешаванд, ки беъдоди ҷиштӣ ё бе қўшидан металли ҷиштӣ аст. Сатҳ 4 бояд дар процесси беъдодӣ созида шавад.

Илтимоси гормии

Ҳамаи ластонҳои беъдодӣ ва чаркашӣ бояд дар гормии илтимос карда шаванд, барои рӯйхаткунӣ дар баробари микроструктура аз як аз роҳҳои зерин:

Беъдоди ғайри муайян ба температуре камтар аз 1500F (815℃) горм карда шавад ва пас аз ин бояд дар хаваи обури гурм карда шавад ё дар камераяи сузиши хаваи мосбат сузӣ карда шавад.

Ластони сталӣ нормализ карда мешавад ва бояд дубори температуреи мунасеби табдил карда шавад, ки дар сталкӯҳи сталӣ таъкид карда мешавад. Дубори температуреи горими дар процесси горими дар температуреи 1550-1750F (845-945 ° C) низ карда мешавад, ва пас аз ин дар фурнуси сузиши хаваи контролшуда бо температуреи асосӣ камtar аз 1550 (845 ° C) сузӣ карда мешавад. Ин роҳ фақат барои процессҳои ластони беъдодӣ мосляк аст.

Бароятиро ба ҳал карда мешавад ва барои температури муодиле кӯмактарин дарҷаи температурӣ, ки аз фабрика таъйин шудааст, дубор гرم карда мешавад.

Агар дар вазифа нусхаи тағирёфтае маълум бошад, нусхагирӣ бояд аз блоки санчидани толаъи, ки аз чоби гормандии сурхшуда гирифта шудааст, кор карда шавад ва бояд таъсирпذīрӣ шавад. Блоки санчидани бояд дар температураро муқайеса карда шавад, дар ин температура барои вақти муоддиле ташвиш карда шавад ва пас аз ин соат дохил карда шавад ва дар температуре зерин аз 600F (315 ° C) сух карда шавад. Блоки санчидани дар дарجةи 8 чоби гормандӣ бояд сух карда шавад ё су карда шавад барои намуди сухшудаи минимали 300F/ (165℃/h) дар температуре зерин аз 600F (315℃).

3. Бранди асосӣ ё дарҷаи чоби продукт

ASTM A333-Grade1, Grade4, Grade6, Grade7, Grade9, Grade10

ASTM A334-Grade1, Grade6, Grade7, Grade9

API 5CT80, L80-1, L803Cr, P110

4. Стандарти иҷрои продукт

GSTM 8333, GSTM 8334, API SPEC 5CT (9th)

5. Хосияти продукт

Ширкит аз сардии писин мудири мекунад, ва бе дарахти худро доред, истифода аз сталҳои сифатвара бо сулиф ва фосфор писин ва туррӣ шимидани ва ҳамчунин оброботкаи кальцийи, мумкин аст ки зiyorати сардии сталро кам кунад ва хушхондагии импактӣ зобоҳои махсулотро баланд кунад. Ширкит 0 "-100C чашмаи сурадор дорад, ки мумкин аст импакт сард ро дар такорори зобаҳо иҷро намояд ва сифат ва стабильӣёни махсулотро таъмин кунад.

6. Муҳити истифодабарии махсулот

Луиҳои A333 ва A334 барои пайплойҳои леди дар дараҷаи температури -45-195C истифода мешаванд, ки барои пайплойҳои леди ва пайплойҳои заминбахши леди истифода шудаанд. Ин луиҳо метавонанд барои пайплойҳои транспорткунандаи суичӣ дар мohитҳои сарсаре истифода шаванд. Кейсинги сарсаремӯдои API5CT асосан барои зоршавӣ дар ноҳотҳои сарсаре истифода мешавад. Луиҳо метавонанд дар температури сарсаре истифода шаванд, ва онҳо ҳамча даражаи зуррӣ, мухоммасзудагӣ, функсиядороӣ хуб ва зудтабдилдороӣ доранд. Ин хусусиятҳо ингилоби истифодашавии луиҳои сарсаремӯди A333GR.6 дар маъмурийатҳои нефть, газ, шimiё ва дигар мақолаҳои саноатӣ расонанд.

7. Дастори гувohnomi калонтар

Диаметри берун: 16мм~323.9мм; Зуҳори дар: 2.0мм~40.0мм

Истифодаҳо:

Барояд аз навбати петрохими, газеҳои табиъӣ, шimiё, барқ, ғори зист ва саршомора дигар истифода мешавад. диапазони истифодабарии ун ҷустуҷӯст, мунсебати он мешоб. Дар линияҳои транспортирувандагии нефть ва газ табиъӣ, ташкилотҳои петрохими, линияҳои системи хавошуда, сушидағир, парвардоҳо, парварди пар, ва ҳамچунин дар маҳфозоти механикӣ, контейнерҳои фишанда, сазовоби курси, сталлий структура, марказҳои ихтимолӣ, марказҳои нümуш, такъирёб кардан машина, судо, анبارҳои дахилшавӣ, тахрир, таъминоти транспортӣ, сотони аэропорт, таҳийи мост, пихр, гаражи салосалӣ, рекламаи берун, тадбиркорӣ ташкилот, ва ташкилоти таъмироти машина ва дигар саноатҳо истифода мешавад.

Ҷустуҷӯҳо:

Стандарти чалак будани лулавӣ сталӣ

| API SPEC 5L | |||

| Номи продукт | Стандарти иҷро | Миқёси (mm) | Коди стал / Дарجةи стал |

| Линияҳои лулавӣ | API 5L | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| Номи продукт | Стандарти иҷро | Миқёси (mm) | Коди стал / Дарجةи стал |

| Чашма | API 5CT | ø114~219 х WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Чубука | API 5CT | ø48.3~114.3 х WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Номи продукт | Стандарти иҷро | Миқёси (mm) | Коди стал / Дарجةи стал |

| Чорхӯрд ва дар зинч ғалтакшуда пайпҳои сталурӣ бе шовад | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Пайпҳои сталурӣ карбонӣ бе шовад ба лаъли гӯманд | ASTM A106 | ø10.3~1200xWT1.0~150 | Гурӯҳ B, Гурӯҳ C |

| Лавҳаҳои таромодӣ ва лавҳаҳои конденсатор аз стал карбонии паст карбонӣ бе шовӣ сармада | ASTM A179 | ø10.3~426x WT1.0~36 | Стал карбонии паст карбонӣ |

| Лавҳаҳои стал карбонии бе шовӣ baraи котлҳои таромодӣ дар фишрӯи боланд | ASTM A192 | ø10.3~426 x WT1.0~36 | Стал карбонии паст карбонӣ |

| Лавҳаҳои таромодӣ ва конденсатор аз стал карбонии мутавосطӣ бе шовӣ сармада | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Лавҳаи беъдод аз чалаки карбонӣ барои котлот ивазгӯшт ва суперхиттер | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Лавҳаи беъдод аз чалаки феритӣ ва аустенитӣ барои котлот ивазгӯшт, суперхиттер ва лавҳаи гузаштан дарменат | ASTM A213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Лавҳаи беъдод аз чалаки карбонӣ ва аллойи барои механикӣ | ASTM A333 | ø1/4"~42"xWTSCH20~XXS | Гр.1, Гр.3, Гр.6 |

| Лавҳаи беъдод ва лавҳаи зулоли челикӣ ва лавҳаи ахбории челикӣ барои истифодаи дар температури пуштак | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Гр.1, Гр.6 |

| Лавҳаи беъдоди челикӣ барои тубҳои гормандозӣ | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Номи продукт | Стандарти иҷро | Миқёси (mm) | Коди стал / Дарجةи стал |

| Лавҳаи челикӣ беъдод барои температури баланд | DIN 17175 | ø10~762 х WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Тубҳои фолидашавӣ аз чалак | DIN 1629 \/ DIN 2391 | ø13.5~762 х WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Тубҳои фолидашавӣ аз чалак | DIN 2440 | ø13.5~165.1 х WT1.8~4.85 | St33.2 |

| Ластоҳои сталӣ бе шовуъ дар мақсади сактсозӣ | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| Bs | |||

| Номи продукт | Стандарти иҷро | Миқёси (mm) | Коди стал / Дарجةи стал |

| Ластоҳои сталӣ бе шовуъ дар тағйирёбии дастгири | BS 970 | ø10~762x WT1.0~120 | Чалбаф карбонӣ |

| Ластоҳои сталӣ бе шовуъ дар чанг ва мубдилони гармия | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Фойдаи конкурентӣ:

1. Сабк ваҳид.

Параметр аз нозд ба шакл қуллӣ, барои он хубтар аст, сабктар аз қуллӣ, ваҳид, ваҳид аз нозд ба шакл қуллӣ 1/5 аст.

2. Муқовим ба корозия ва гурмсозии.

Ба корозия муқовимати хуб дорад ва гурмсозии, хубтар аз қуллӣ, A333 муқовимат ба зурат, кишт, намак ва корозияи атмосферӣ, гурмсозии, муқовимати хуб дорад ва фарги муқовимат, нахостемони регулярӣ надорад, мудати корӣ дар баробари 15 сол аст.

3, безформӣ ва антистатик.

Муқовимати антистатикӣ хуб дорад, хубтар аз пайпҳои обињ, пайпҳои беъдафторӣ бо эластичӣ баланд, бармегардонии механикиӣ, безформӣ ва антистатик, пайпҳои беъдафторӣ хусусиятҳои механикиӣ хуб доранд, содом ва сулӯхӣ раҳгоштааст ва гир.

Ҷамъиятимиз дуستдор ва беҳтар аст ки аз шумо хабар дошта бошад!