| Lugar ng pinagmulan: | Shandong, China |

| Pangalan ng Brand: | jinzheng |

| Numero ng Modelo: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grade1、Grade3、Grade4、Grade6、Grade7、Grade8、Grade9、Grade10、Grade11 |

| Sertipikasyon: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| Minimum Order Quantity: | 1 tonelada |

| Presyo: | $650/ton |

| Packaging Details: | Standard ng Pagpapakita sa Export (Sa mga bundle Nylon bags, kaso ng kahoy o ayon sa kinakailangan) |

| Delivery Time: | 15-20 araw |

| Payment Terms: | FOB 30% T/T, 70% bago ang pag-shipping |

| CIF 30% bayad ng hara at ang balanse ay babayaran bago gumawa ng pag-shipping | |

| o Irrevocable 100% L/C sa paningin | |

| Kakayahang Suplay: | 2000 Ton/Tons per Month |

Mabilis na Detalye:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984,tubong walang sikid,Tubong Carbon at Alloy Steel para sa Mekanikal na Gamit

Ang tubo ng mababang temperatura A333 ay madalas gamitin sa petrokimika, likas na gas, kimika, elektrisidad, pagsisigaw at iba pang mga larangan. Ang malawak na sakop ng mga aplikasyon nito ay maayos at maanghang, Ginagamit ito sa mga pipa ng transmisyong langis at likas na gas, petrokimikang kagamitan, mga pipa ng sistema ng aircon, cooler, generator ng buhawi, pati na rin sa mekanikal na pagproseso, presyo na kapus-palad, paggawa ng boiler, pangkalakhan na strukturang bakal, malalaking lugar, sentrong pang-exhibit, lifting na makina, paggawa ng barko, storage shelves, dekorasyon, transportasyon na faciliti, paggawa ng paliparan, supot ng tulay, suporta sa mina, tatlong-dimensyonal na parking, panlabas na adverting, fitness equipment, Paggawa ng sasakyan at iba pang industriya.

Kailangang Kimikal

| Element | Pormulasyon, % | ||||||||

| Berkado 1A | Berkado 3 | Berkado 4 | Berkado 6A | Berkado 7 | Grado 8 | Berkado 9 | Berkado 10 | Berkado 11 | |

| Karbono, max | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Ang manganese | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 max | 0.90 max | 0.40-1.06 | 1.15-1.50 | 0.60 Max |

| Berilyo, maks | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Sulphur, maks | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Mga silicon | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 min | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 max |

| Nikel | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 Max | 35.0 -37.0 |

| Kromium | - | - | 0.44-1.01 | - | - | - | - | 0.15 max | 0.50 max |

| Copper | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 max | - |

| Aluminyo | - | - | 0.04-0.30 | - | - | - | - | 0.06 max | - |

| Vanadium, max | - | - | - | - | - | - | - | 0.12 | - |

| Columbium, max | - | - | - | - | - | - | - | 0.05 | - |

| Molybdenum, max | - | - | - | - | - | - | - | 0.05 | 0.50 max |

| Cobalt | - | - | - | - | - | - | - | - | 0.50 max |

Mga Requiro ng Tensile

| Berkado 1 | Berkado 3 | Berkado 6 | Berkado 7 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Lakas ng pagpapalo, minPalatandaan ng pagpapalo, min | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Longitudinal | Transwerse | Ang mga pang-habang | Transwerse | Ang mga pang-habang | Transwerse | Ang mga pang-habang | Transwerse | |

| Paghaba sa loob ng 2 in. o 50mm, (o 40). min, %: Pangunahing pinakamababang paghaba para sa mga dingding na 5/16 in. (8 mm) at higit pa sa madikdik, pruwebang strip at para sa lahat ng maliit mga sukat na itinutulak sa buong seksyon kung pamantayan na bilog na 2-into o 50-mm gage haba o mas maliit na sukat ng proporsyon subok na may gage na haba tumbasan sa 4D (apat beses ang diyametro) ay ginagamitSa mga pagsubok ng tirahan, isang deduksyon para sa bawat 1/32 in. [0.8 mm] babaw sa biyak na kalat nang humahaba sa 5/16 in. (8 mm) mula sa pangunahing minimum na pagtaas ng sumusunod na porsiyento |

35 28 1.75B | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| Grado 8 | Berkado 9 | Berkado 10 | Berkado 11 | |||||

| psi | MPa | psi | MPa | psi | MPa | psi | MPa | |

| Lakas ng pagpapalo, minPalatandaan ng pagpapalo, min | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Longitudinal | Transwerse | Ang mga pang-habang | Transwerse | Ang mga pang-habang | Transwerse | Ang mga pang-habang | ||

| Paghaba sa loob ng 2 in. o 50mm, (o 40). min, %: Pangunahin minimum na pagtaas para sa mga pader na 5/16 in. (8 mm) at higit pa sa kalakahan, strip tests. at para sa lahat ng maliit na laki na itinestong sa buong bahagi Kapag standard round 2-in. o 50-mm gage haba o proporsyonal na mas maliit na laki ng test specimen na may ang gage haba na katumbas ng 4D (apat beses ang diyametro) ay ginagamit Para sa strip tests, isang deduksyon para sa bawat 1/32 in. [0.8 mm] babaw sa kalakahan ng pader mula sa 5/16 in. (8 mm) mula sa basic minimum pagtaas ng sunod na porsentaheng |

22 16 1.25B | --- --- --- | 28 --- 1.50B | --- --- --- | 22 16 1.25B | --- --- --- | 18A --- --- | |

Paglalarawan

1. Maikling introduksyon ng produkto

Ang low-temperature seamless steel pipe ay pangunahing ginagamit sa petroleum, kemikal, natural gas at coal bilang mga materyales ng ethylene, propylene, urea, synthetic ammonia, N-P-K compound fertilizer at farmasiyang industriya para sa paglilinis, pagsasalinaw, desulfurization at degrease produksyon, pati na rin ang paggawa ng cryogenic equipment, ultra-low temperature storage, transportasyon ng ultra-low temperature liquefied gas pipeline at pipe components. Ang internasyonal na sistema ng low-temperature seamless steel pipe ay kinakatawan ng ASTM A333/A333M-2011 (doroonhin na US standard), na maaaring gamitin sa mababang temperatura hanggang -196℃. Sa kasalukuyan, ang produksyon at pagtanggap ng low-temperature seamless steel pipe sa buong mundo ay halos gumagamit ng US standard, at ang lokal na disenyo ay umuukol din sa US standard. Sa walong klase ng US standard na cryogenic pipe, ang Gr.6 ay madalas gamitin sa petro-kemikal na industriya at sa pag-uubat ng likido sa mababang temperatura at malamig na rehiyon, at ang taunang demand sa US at Europe market ay higit sa 20,000 t.

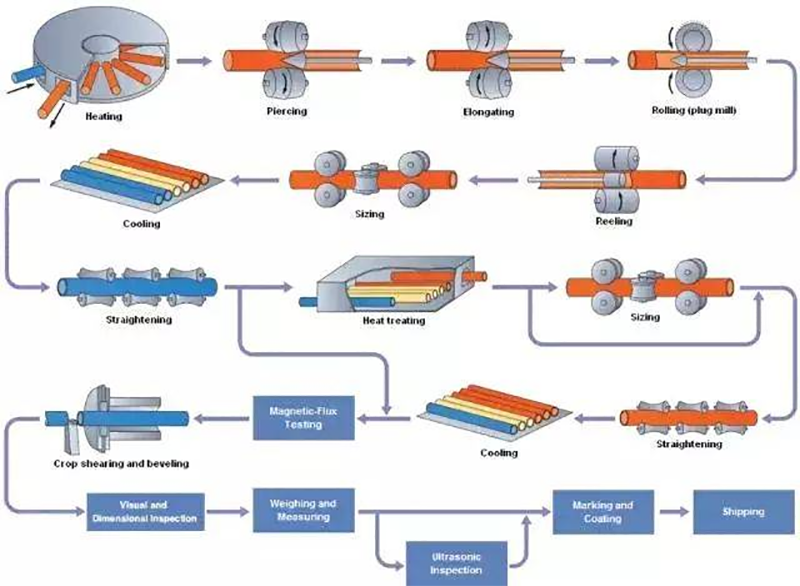

2. Proseso ng paggawa

Paggawa - Ginagawa ang mga tube sa pamamagitan ng mga proseso ng pagweld na seamless o hindi nagdadagdag ng filler metal. Ang antas 4 ay gagamitin ang proseso ng seamless.

Paggamot sa init

Dapat ipormalan ang lahat ng seamless at naiweld na mga pipe upang kontrolin ang kanilang microstructure sa pamamagitan ng isa sa mga sumusunod na paraan.

Pagkakaroon ng pagsasanay na pantay na hindi bababa sa 1500F (815℃) para sa positibong pagsasanay, at pagkatapos ay paglilito o paglilito sa chamber ng kontroladong hangin ng oxygen furnace.

Ang pipa ng bakal ay binubuklod at binabawas muli sa isang wastong temperatura ng tempering tulad ng tinukoy ng steel mill. Ang muling pagsasanay ng pipa ay maayos na kontrolado ang prutas ng pagproseso ng init, kaya nakontrol ang operasyong temperatura ng hot forming sa loob ng saklaw ng temperatura ng hot forming mula 1550 hanggang 1750F (845-945 ° C), at pagkatapos ay ini-init sa kontroladong gas oxygen furnace na may temperatura na hindi bababa sa 1550 (845 ° C). Ang paraan na ito ay lamang ayaptable para sa mga proseso ng tube na walang sinturon.

Itratramo at ibinabawi sa wastong temperatura ng tempering ayon sa pagtukoy ng fabrica.

Kapag itinakda sa order, ang sample ay dapat gupitin mula sa test block na mayroong tiyak na kalat, na kinukuha mula sa steel pipe ng heat treated stone, at dapat alisin ang stress. Ang test block ay babarilin nang paulit-ulit patungo sa tinukoy na temperatura, iimbulis sa temperatura na ito para sa tinukoy na oras, at kung sakali't ma-init muli hanggang hindi umuubos sa 600F (315°C). Ang test block ng grado 8 na steel pipe ay dapat hawakan o tubig-lamig sa pinakamababang rate ng paglilito na 300F/hour (165℃/h) patungo sa temperatura na hindi umuubos sa 600F (315℃).

3. Ang pangunahing brand o klase ng produkto

ASTM A333-Grade1、Grade4、Grade6、Grade7、Grade9、Grade10

ASTM A334-Grade1、Grade6、Grade7、Grade9

API 5CT80、L80-1、L803Cr、P110

4. Mga pamantayan ng pagsasaayos ng produkto

GSTM 8333、 GSTM 8334、 API SPEC 5CT (9th)

5. Katangian ng produkto

Ang kompanya ay resistente sa mababang temperatura at walang vascular, ang paggamit ng mababang sulip at mababang fosporo na malinis na bakal at kalsipikasyon treatment, maaaring maubos ang mababang temperatura brittle ng bakal, ipabuti ang impact toughness ng mga produkto. Mayroong 0 "-100C cooling tank ang kompanya, na maaaring magbigay ng mababang temperatura impact test pribadong pansinin upang makamit ang kalidad at estabilidad ng produkto.

6. Gamit ng produktong kapaligiran

Ginagamit ang mga cryogenic tube na A333 at A334 para sa -45-195C klase ng cryogenic lele vessel pipes at cryogenic heat exchanger pipes. Maaari din itong gamitin para sa mga pipe na transportasyon ng likido sa mababang temperatura na kapaligiran. Ang API5CT na maaangkop sa mababang temperatura na casing ay pangunahing ginagamit para sa pag-uusap ng mga bakwit sa napakalumang lugar. Ang steel pipe ay maaaring gamitin sa napakalumang temperatura, ngunit mayroon ding mataas na lakas, korosyon-resistensya, mabuting proseso at kakayahan sa pagsisiwelas. Ang mga katangian na ito ang nagiging sanhi kung bakit malawak ang paggamit ng A333GR.6 low temperature steel pipe sa mga industriyal na larangan tulad ng langis, natural gas, at kimika.

7. Alcance ng produktong spepsifikasi

Labas na diyametro: 16mm~323.9mm; Laktos ng pader: 2.0mm~40.0mm

Mga aplikasyon:

Madalas gamitin sa petrokimiko, likas na gas, kimika, elektrikong kapangyarihan, pagsisilaw at iba pang mga larangan. Ang malawak na sakop ng kanyang gamit, maayos, Sa langis, transmisyong pipa ng likas na gas, petrokemikal na kagamitan, pipa ng sistema ng aircon, cooler, generator ng bapor, subalit ginagamit din sa mekanikal na proseso, presyo ng kapus-palad, paggawa ng boiler, steel na estraktura ng gusali, malalaking lugar, sentrong pang-exhibit, bulok na makina, pamamaripok, storage na balindig, dekorasyon, transportasyong facilidad, pagsasaayos ng paliparan, suporta ng tulay, suporta ng mina, tatlong-dimensional na parkingan, panlabas na adhiking, fitness na kagamitan, paggawa ng sasakyan at iba pang industriya

Mga Espesipikasyon:

Pantayan ng seamless na tubo

| API SPEC 5L | |||

| Pangalan ng Produkto | Pamantayan ng Tagapagpaganap | Dimensyon (mm) | Steel Code / Steel Grade |

| Mga Pipa ng Linya | API 5L | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| Ang mga ito ay dapat na may mga sumusunod na mga katangian: | |||

| Pangalan ng Produkto | Pamantayan ng Tagapagpaganap | Dimensyon (mm) | Steel Code / Steel Grade |

| Casing | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubing | API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Pangalan ng Produkto | Pamantayan ng Tagapagpaganap | Dimensyon (mm) | Steel Code / Steel Grade |

| Itim at Hot-Dipped Zinc-Coated Seamless Tansong mga Tubo | Ang ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Seamless Carbon Steel Pipes para sa Mataas na Temperatura Service | Astm a106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Seamless Cold-Drawn Maiikling Carbon Steel Heat-Exchanger at Condenser Tubes | ASTM A179 | ø10.3~426x WT1.0~36 | Low carbon steel |

| Seamless Carbon Steel Boiler Tubes para sa Mataas na Presyon | ASTM A192 | ø10.3~426 x WT1.0~36 | Low carbon steel |

| Walang-sambalang Gulong na Nakalawak ng Malamig na Talahib na Tubo para sa Heat-Exchanger at Condenser | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Walang-sambalang Tubo ng Matamis na Carbon para sa Boiler at Superheater | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Walang-sambalang Tubo ng Ferritic & Austenitic na Talahib para sa Boiler, Superheater, at Heat-Exchanger | Astm a213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Bulubol na Carbon at Alloy Steel para sa Mekanikal na Tubing | Ang ASTM A333 | ø1/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Bulubol at Nasusumang Carbon Steel Pipes at Alloy Steel Pipes para sa Gamit sa Maikling Temperatura | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Bulubol na Cold-Drawn Carbon Steel Feedwater Heater Tubes | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Pangalan ng Produkto | Pamantayan ng Tagapagpaganap | Dimensyon (mm) | Steel Code / Steel Grade |

| Mga Tubo ng Steel na Seamless para sa Taas na Temperatura | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Mga Tubo ng Steel na Seamless | DIN 1629\/ DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Mga Tubo ng Steel na Seamless | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Mga Tubo ng Plastik na Walang Sikid para sa Estruktural na Layunin | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| Pangalan ng Produkto | Pamantayan ng Tagapagpaganap | Dimensyon (mm) | Steel Code / Steel Grade |

| Mga Tubo ng Plastik na Walang Sikid para sa Estrukturang Pang-Makinang | BS 970 | ø10~762x WT1.0~120 | Carbon Steel |

| Mga Tubo ng Plastik na Walang Sikid para sa Boiler at Heat Exchangers | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Kalakihan ng Pagkakataon:

1. Mababang timbang.

Ang parameter ay 1/5 ng kwadrado na bakal, kaya't mas mabuting pag-aaruga at liwanag na pagganap, mas madali sa pag-uulat kaysa sa kwadrado na bakal, at ang timbang nito ay lamang 1/5 ng kwadrado na bakal.

2. Resistensya sa karumihan at taas na temperatura.

May mabuting resistensya sa korosyon at mataas na temperatura, mas mabuti kaysa sa kwadrado na bakal, A333 resistensya sa asido, alkali, asin at kapaligiran ng atmospera sa korosyon, resistensya sa mataas na temperatura, mabuting resistensya sa pagnanakbo at pagkapagod, hindi kinakailangang magkaroon ng regular na pamamahala, maaaring maabot ang epektibong takda ng serbisyo ng higit sa 15 taon.

3, walang deformasyon at anti-static.

May mabuting katangian ng antistatic, mas mabuti kaysa sa pangkalahatang tubo ng bakal, mabuting elastisidad ang mga seamless pipes, muli gamitin sa makinarya at equipment, walang memorya, walang deformasyon, at antistatic, may malaking katangian ng mekanikal ang seamless pipes, madali ang pagproseso, etc.

Ang aming mapagkaibigan na koponan ay mahilig na makarinig mula sa iyo!