| Üretim Yeri: | Shandong, Çin |

| Marka Adı: | jinzheng |

| Model Numarası: | 16MnDG、10MnDG、09DG、09Mn2VDG、06Ni3MoDG、ASTM A333-Grade1、Grade3、Grade4、Grade6、Grade7、Grade8、Grade9、Grade10、Grade11 |

| Sertifikasyon: | API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, GS, ISO9001 |

| En Düşük Sipariş Miktarı: | 1 Ton |

| Fiyat: | $650/ton |

| Paketleme Detayları: | İhracat Paketleme Standartı (Nylon poşetlerde, ahşap kasalarda veya talep edilen şekilde) |

| Teslimat Süresi: | 15-20 gün |

| Ödeme Şartları: | FOB 30% T/T, kargo öncesi 70% |

| CIF 30% ön ödeme ve kargo yapmadan önce kalan miktarın ödeneceği | |

| veya Geri Alınamaz 100% L/C görünürde | |

| Tedarik Kapasitesi: | 2000 Ton/Ay |

Hızlı Detay:

16MnDG,10MnDG,06Ni3MoDG,GB/T6479,GB/T18984, seemless boru, Mekanik Tubing için Seamless Karbon ve İhtilaflı Çelik

A333 düşük sıcaklık çelik borusu petrokimya, doğalgaz, kimya, elektrik enerjisi, ısıtma ve diğer alanlarda yaygın olarak kullanılmaktadır. Uygulama alanı geniş, esnektir; yağ, doğal gaz taşıma hattlarında, petrokimya ekipmanında, klima sistem borularında, soğutucularda, buhar jeneratörlerinde kullanılır ve ayrıca makine işlemede, basınç kapakları, buhar kazanlarının imalatında, yapı çelik yapısı, büyük mekanlar, sergilere merkezleri, kaldırma makineleri, gemi inşaatta, depolama raftları, dekorasyon, ulaşım tesisi, havaalanı inşaatı, köprü destekleri, üç boyutlu park yeri, Outdoor reklam, fitness ekipmanı, araç üretimi ve diğer endüstrilerde kullanılmaktadır.

Kimyasal Gereksinimler

| Eleman | Bileşim,% | ||||||||

| Sınıf 1A | Sınıf 3 | Derece 4 | Sınıf 6A | Sınıf 7 | 8. sınıf | Sınıf 9 | Sınıf 10 | Sınıf 11 | |

| Karbon,maks | 0.30 | 0.19 | 0.12 | 0.30 | 0.19 | 0.13 | 0.20 | 0.20 | 0.10 |

| Mangan | 0.40-1.06 | 0.31-0.64 | 0.50-1.05 | 0.29-1.06 | 0.90 maks | 0.90 maks | 0.40-1.06 | 1.15-1.50 | 0.60 Maks |

| Fosfor, maks | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.035 | 0.025 |

| Karbon, maks | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.025 | 0.015 | 0.025 |

| Silikon | - | 0.18- 0.37 | 0.08- 0.37 | 0.10 min | 013- 0.32 | 0.13 0.32 | - | 0.10-0.35 | 0.35 maks |

| Nikel | - | 3.18- 3.82 | 0.47-0.98 | - | 2.03 2 57 | 8.40 9.60 | 1.60 2.24 | 0.25 Maks | 35.0 -37.0 |

| Krom | - | - | 0.44-1.01 | - | - | - | - | 0.15 maks | 0.50 maks |

| Bakır | - | - | 0.40-0.75 | - | - | - | 0.75-1.25 | 0.15 maks | - |

| Alüminyum | - | - | 0.04-0.30 | - | - | - | - | 0.06max | - |

| Vanadyum, max | - | - | - | - | - | - | - | 0.12 | - |

| Kolumbiyum, max | - | - | - | - | - | - | - | 0.05 | - |

| Molibden, max | - | - | - | - | - | - | - | 0.05 | 0.50 maks |

| Kobalt | - | - | - | - | - | - | - | - | 0.50 maks |

Çekme Dayanımı Gereksinimleri

| 1. sınıf | Sınıf 3 | 6. Derece | Sınıf 7 | |||||

| psi | Mpa | psi | Mpa | psi | Mpa | psi | Mpa | |

| Çekme dayanımı, min Esneklik dayanımı, min | 55 00030 000 | 380205 | 65 00035 000 | 450240 | 60 00035 000 | 415240 | 65 00035 000 | 450 240 |

| Uzunluğa göre | Transwerse | Uzunluk | Transwerse | Uzunluk | Transwerse | Uzunluk | Transwerse | |

| 2 in. veya 50mm'de (veya 40) uzama. min, %:Temel minimum uzama için duvarlar 5/16 in. (8 mm) ve üzerinde olanlar için kalınlık, şerit testleri ve tüm küçük boyutlar için tam kesimde test edilen boyutlar ne zaman standart Yuvarlak 2 inç veya 50 mm ölçüm uzunluk veya orantılı olarak daha küçük boyut ölçüm uzunluğuna sahip deneme örneği 4D'ye (çapın 4 katı) eşit olan kullanılır şerit testleri için, her 1/32 inç [0.8 mm] azalma başına indirim duvar kalınlığı 5/16 inç (8 mm)'den düşükse temel minimum uzama oranından yapılan düşüm aşağıdaki yüzde oranı kadar yapılır 35 28 1.75B |

en az şu yüzde değerlerdir | 25 20 1.25B | 30 22 1.50B | 20 14 1.00B | 30 22 1.50B | 16.5 12 1.00B | 30 22 1.50B | 22 14 1.00B |

| 8. sınıf | Sınıf 9 | Sınıf 10 | Sınıf 11 | |||||

| psi | Mpa | psi | Mpa | psi | Mpa | psi | Mpa | |

| Çekme dayanımı, min Esneklik dayanımı, min | 100 00075 000 | 690515 | 63 00046 000 | 435310 | 80 00065 000 | 550450 | 65 00035 000 | 450 240 |

| Uzunluğa göre | Transwerse | Uzunluk | Transwerse | Uzunluk | Transwerse | Uzunluk | ||

| 2 in. veya 50mm'de (veya 40). min, %: Temel uzama 5/16 in. (8 mm) ve üzerindeki duvarlar için minimum uzama kalınlığında, şerit testleri ve tüm küçük boyutlar için test edilmiştir tam kesimde. Standart yuvarlak 2-inci veya 50-mm ölçüm uzunluğu veya orantılı olarak daha küçük boyutlu test örneği ile ölçüm uzunluğu 4D'ye (çapın 4 katı) eşittir şerit testleri için, duvar kalınlığında her 1/32 in. [0.8 mm] azalma durumunda 5/16 in. (8 mm)'den düşükse temel minimum uzama oranından çıkarım yapılır aşağıdaki yüzde oranı 22 16 1.25B |

--- --- --- | --- --- --- | 28 --- 1.50B | --- --- --- | --- --- --- | --- --- --- | 18A --- --- | |

Açıklama

1. Ürün kısa tanıtımı

Düşük sıcaklıkta kullanılabilecek seemless çelik boru, çoğunlukla petrol, kimya, doğalgaz ve kömür gibi ham madde kaynaklarını etilen, propilen, üre, sentetik amonyak, N-P-K bileşik gübre ve ilaç endüstrisi temizleme, tasfiye, desenkleştirme ve yağ çıkarma üretiminde kullanılır. Ayrıca, düşük sıcaklıklarda kullanılan ekipman üretimi, ultra-düşük sıcaklıkta depolama, taşıma ve ultra-düşük sıcaklıkta sıvı gaz boru ve boru parçaları için de kullanılır. Uluslararası düşük sıcaklıkta kullanılabilecek seemless çelik boru sistemi, ASTM A333/A333M-2011 (aşağıda Amerikan standartı olarak adlandırılır) ile temsil edilir ve -196℃'ye kadar olan düşük sıcaklık ortamlarında uygun görülmektedir. Şu anda, dünyanın dört bir yanındaki düşük sıcaklıkta kullanılabilecek seemless çelik borunun üretimine ve kabul edilmesine çoğunlukla Amerikan standartı uygulanır ve yerli tasarım da Amerikan standartına başvurur. Amerikan standartı soğuk boru dokuz sınıfından, Gr.6 petrokimya endüstrisinde yaygın olarak kullanılmaktadır ve düşük sıcaklık ve soğuk bölgelerdeki akışkan taşıma için tercih edilmektedir. Bu ürünün yıllık talebi, ABD ve Avrupa pazarlarında 20.000 tonu aşmaktadır.

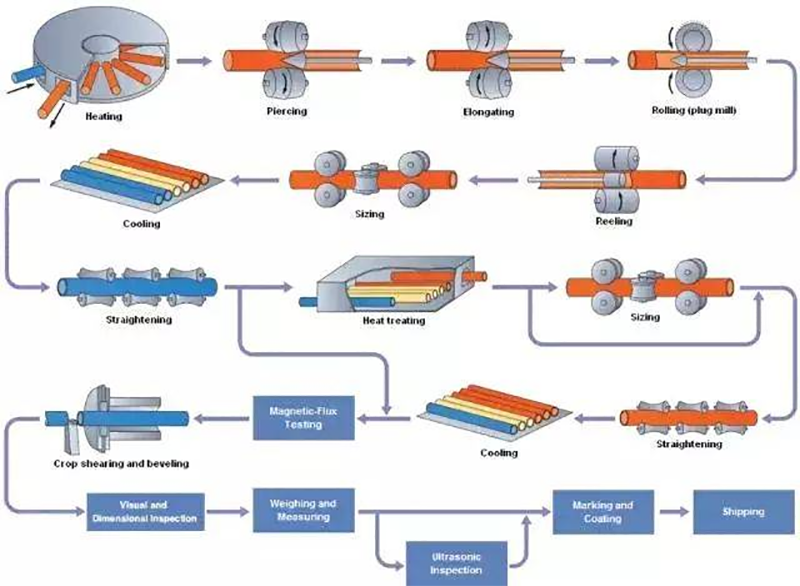

2. Üretim süreci

Üretim - Borular, doldurma metali eklemeyen veya eklemeyen kaynaklama süreçleriyle yapılır. Seviye 4, seemless süreçle yapılmalıdır.

Isı Tedavisi

Tüm seemless ve kaynaklanmış boruların mikro yapısı birbiriyle aşağıdaki yöntemlerden biriyle kontrol edilerek ısı işleme uygulanacaktır.

Olumlu ısı işleme için en az 1500F (815℃) dereceye eşit şekilde ısıtılmış ve ardından hava soğutulması ya da kontrol edilen hava oksijen fırınınin soğutma odasında soğutulmuştur.

Çelik boru normalleştirilmiş ve çelik fabrikası tarafından belirlenen uygun bir temperatur sıcaklığına yeniden ısıtılır. Boru yeniden ısıtma iyi sıcaklık işlemini kontrol eder böylece sıcak biçimlendirme işlem sıcaklığı 1550 ila 1750F (845-945 ° C) sıc sıcaklık aralığında kontrol edilir ve ardından başlangıç sıcaklığı en az 1550 (845 ° C) olan kontrol gaz oksijen fırınında soğutulur. Bu yöntem sadece seemsiz tüp süreçleri için uygundur.

Fabrika tarafından belirlenen uygun temperleme sıcaklığına göre yeniden ısıtılır ve işlenir.

Siparişte belirtilmiş ise, numune kalınlık test bloğu üzerinden kesilir ve bu test bloğu ısıl tedavi edilmiş çelik borudan alınır ve stres azaltma işlemine tabi tutulur. Test bloğu belirtilen sıcaklığa adım adım ısıtılarak, bu sıcaklıkta belirtilen süre boyunca nemlendirilir ve ardından 600F (315 ° C)'dan daha düşük bir sıcağa kadar soğutulur. 8. sınıf çelik boru için test bloğu hava ile veya su ile en az 300F / (165℃ / saat) soğuma oranında 600F (315℃)'dan daha düşük bir sıcağa kadar soğutulur.

3. Ürünün ana markası veya çelik sınıfı

ASTM A333-Grade1、Grade4、Grade6、Grade7、Grade9、Grade10

ASTM A334-Grade1、Grade6、Grade7、Grade9

API 5CT80、L80-1、L803Cr、P110

4. Ürün uygulama standartları

GSTM 8333、 GSTM 8334、 API SPEC 5CT (9th)

5. Ürün özelliği

Şirket, düşük sıcaklıkta dirençli ve damarlı değil, düşük kükürt ve düşük fosforlu yüksek safiyetli çelik kullanılarak ve kalsifikasyon tedavisi uygulanarak, çeliğin düşük sıcaklık Britanyası etkili bir şekilde azaltılabilir, ürünün çarpmaya karşı dayanıklılığı artırılır. Şirket, 0 "-100C soğutma tankına sahiptir, bu da ürünlerin kalitesini ve kararlılığını sağlamak için toplu olarak düşük sıcaklık çarpması deneyi yapabilmesini sağlar.

6. Ürün kullanım ortamı

A333 ve A334 kriyojenerik borular, -45 ila -195C derecesi arasındaki kriyojenerik lele kaplama boru hatları ve kriyojenerik ısı değiştirici boru hatları için kullanılır. Ayrıca düşük sıcaklık ortamlarında sıvı taşıma boru hatları olarak da kullanılabilirler. API5CT düşük sıcaklığa dayanıklı kasa boruları, özellikle soğuk bölgelerdeki sondaj operationsı için kullanılır. Çelik boru, çok düşük sıcaklıklarda kullanılabilirken, aynı zamanda yüksek dayanım, korozyon direnci, iyi işleme yeteneği ve kaydırma kabiliyetine sahiptir. Bu özellikler, A333GR.6 düşük sıcaklıklı çelik borunun petrol, doğalgaz, kimya ve diğer endüstriyel alanlarda yaygın bir şekilde kullanılmasını sağlar.

7. Ürün belirtimi aralığı

Dış çap: 16mm~323.9mm; Duvar kalınlığı: 2.0mm~40.0mm

Uygulamalar:

Petrokimya, doğalgaz, kimya, elektrik gücü, ısıtma ve diğer alanlarda yaygın olarak kullanılır. Uygulama alanlarının genişliği, esnektir; petrol ve doğalgaz taşıma boru hattlarında, petrokimya ekipmanında, klima sistemi borularında, soğutucularda, buhar jeneratörlerinde kullanılır ve ayrıca makine işlemede, basınç kapları, buhar kazanı imalatında, yapı çelik yapısı, büyük mekanlar, sergi merkezleri, kaldırma makineleri, gemilik, depolama rafı, dekorasyon, ulaşım tesisleri, havaalanı inşaatında, köprü desteği, maden desteği, üç boyutlu park yeri, dış reklam, fitness ekipmanı, Taşıt imalatı ve diğer endüstrilerde kullanılır.

Özellikler:

Sondaj çelik boru standartları

| API SPEC 5L | |||

| Ürün Adı | Yürütme Standardı | Boyut (mm) | Çelik Kodu / Çelik Sınıfı |

| Hat Boruları | Api 5l | ø10.3~1200xWT1.0~120 | A, B, X42, X46, X52, X60, X70, X80, PSL1 / PSL2 |

| API SPEC 5CT | |||

| Ürün Adı | Yürütme Standardı | Boyut (mm) | Çelik Kodu / Çelik Sınıfı |

| Kasa | API 5CT | ø114~219 x WT5.2~22.2 | J55, K55, N80, L80, P110 |

| Tubing | API 5CT | ø48.3~114.3 x WT3.2~16 | J55, K55, N80, L80, P110 |

| ASTM / ASME | |||

| Ürün Adı | Yürütme Standardı | Boyut (mm) | Çelik Kodu / Çelik Sınıfı |

| Siyah ve Sıcak-Yüzeyli Zinkli Çelik Borular | ASTM A53 | ø10.3~1200xWT1.0~150 | Gr.A, Gr.B, Gr.C |

| Yüksek Sıcaklıkta Kullanıma Uygun Kaynaksız Çelik Borular | Astm a106 | ø10.3~1200xWT1.0~150 | Gr.B, Gr.C |

| Düşük Karbonlu Soğuk Çekme Çelik Isı Değiştirici ve Buhar Tozu Boruları | ASTM A179 | ø10.3~426x WT1.0~36 | Düşük karbonlu çelik |

| Yüksek Basınclı Kaynaksız Çelik Demirçubukları | ASTM A192 | ø10.3~426 x WT1.0~36 | Düşük karbonlu çelik |

| Kaydırılmamış Soğuk Çekilmiş Orta İmalat Fırınlı Çelik Isı Değiştirici ve Buhar Tozu Boruları | ASTM A199 | ø10.3~426 x 1.0~36 | T5, T22 |

| Kaydırılmamış Orta Karbonlu Çelik Buhar Fırını ve Üstısıl Boruları | ASTM A210 | ø10.3~426 x WT1.0~36 | A1, C |

| Kaydırılmamış Ferritik ve Austenitik İmalat Fırınlı Çelik Buhar Fırını, Üstısıl ve Isı Değiştirici Boruları | Astm a213 | ø10.3~426 x WT1.0~36 | T5, T9, T11, T12, T22, T91 |

| Mekanik Boru İçin Kaydırımsız Karbon ve İnalloy Çelik | ASTM A333 | ø1/4"~42"xWTSCH20~XXS | Gr.1, Gr.3, Gr.6 |

| Düşük Sıcaklıkta Kullanım için Kaydırımsız ve Kaynaklanmış Karbon Çelik Borular ve İnalloy Çelik Borular | ASTM A334 | ø1/4"~4"xWTSCH20~SCH80 | Gr.1, Gr.6 |

| Soğuk Çekme Yöntemiyle Üretilen Karbon Çelik Besin Su Isıtıcı Boruları | ASTM A556 | ø10.3~426 x WT1.0~36 | A2, B2 |

| DIN | |||

| Ürün Adı | Yürütme Standardı | Boyut (mm) | Çelik Kodu / Çelik Sınıfı |

| Yüksek Sıcaklık için Kaymasız Çelik Borular | DIN 17175 | ø10~762 x WT1.0~120 | St35.8, St45.8, 10CrMo910, 15Mo3, 13CrMo44, STPL340, STB410, STB510, WB36 |

| Kesintisiz çelik tüpler | DIN 1629 / DIN 2391 | ø13.5~762 x WT1.8~120 | St37.0, St44.0, St52.0, St52.3 |

| Kesintisiz çelik tüpler | DIN 2440 | ø13.5~165.1 x WT1.8~4.85 | St33.2 |

| Yapı Amacı için Kaynaksız Çelik Borular | DIN 2393 | ø16~426 x WT1.0~36 | RSt34-2, RSt37-2, RSt44-2, St52 |

| BS | |||

| Ürün Adı | Yürütme Standardı | Boyut (mm) | Çelik Kodu / Çelik Sınıfı |

| Makina Yapısı için Kaynaksız Çelik Borular | BS 970 | ø10~762x WT1.0~120 | Karbon Çeliği |

| Kettle ve Isı Değiştirici için Kaynaksız Çelik Borular | BS 3059 | ø10~762x WT1.0~120 | 360,410,440,460, 490 |

Rekabet Avantajı:

1. Hafif ağırlık.

Parametre kare çeliğin 1/5'i olduğundan, daha iyi ağırlık ve hafif performansı vardır, kare çeliktan daha hafif olup, ağırlığı yalnızca kare çeliğin 1/5'idir.

2. Korozyon ve yüksek sıcaklık direnci.

İyi korozyon ve yüksek sıcaklık direncine sahiptir, kare çeliğden daha iyidir, A333 asit, alkol, tuz ve atmosfer ortamına karşı korozyon direncine sahiptir, yüksek sıcaklığa dayanır, iyi şok direnci ve yorgunluk direncine sahiptir, düzenli bakım gerekmez, etkin hizmet ömrü 15 yıldan fazla olabilir.

3, deformasyon olmadan ve antistatik.

İyi antistatik özelliklere sahiptir, sıradan çelik borularından daha iyidir, makine cihazlarında tekrar kullanılabilen, elastiklikte olan, belleği olmayan, deformasyonsuz ve antistatik olan katı无缝borular, mükemmel mekanik özelliklere sahiptir, kolay işlenebilir vb.

Dostça ekibimiz sizden haber almayı çok ister!