| Місце походження: | Місто Ляоченг, провінція Шаньдун, Китай |

| Торгова марка: | Shandong Liaocheng Jinzheng Steel pipe Co., LTD |

| Номер моделі: | Фарбований котел з покриттям/PPGI/Хвильова плита |

| Сертифікація: | ISO/SGS |

| Мінімальна кількість замовлення: | 5 тон |

| Ціна: | 580$/ТОН |

| Деталі упаковки: | Експортний стандартний пакет |

| Час доставки: | 7-10 днів |

| Умови оплати: | TT або LC |

| Способи постачання: | 700тон/тиждень |

Опис:

Фарбований катанка - це продукт, виготовлений з готуючої листини методом горячої оцинковки, горячої алюмінієво-цинкової окустачування, електрооцинковки тощо, який піддається передобробці поверхні (хімічна деґрасування та хімічна конверсійна обробка), а потім наноситься одна або кілька шарів органічного покриття на поверхню, після чого йде запікання та закріплення. Він отримує назву за фарбованою стальню катанкою, покритою різними органічними покриттями різних кольорів, скорочено - фарбована катанка.

Класифікація основ фарбованої катанки:

Основа горячої оцинковки

Продукт, отриманий шляхом нанесення органічного покриття на лист горячої оцинковки, є листом горячої оцинковки з фарбованим покриттям. Крім захисного ефекту цинку, органічне покриття на поверхні фарбованої листини горячої оцинковки також забезпечує ізоляційну захист та запобігає корозії, що призводить до більш довгого терміну служби, ніж у листа горячої оцинковки.

Основа горячої алюмінієво-цинкової

Використання горячо-галуженої алюмінієво-цинкової стальної плити (55% Al Zn) як нового покривального підложа. Корозійна стійкість горячо-галуженої алюмінієво-цинкової плити в 2-5 разів вища, ніж у горячо-галуженої цинкової плити. Неперервне або перерваний використовування при температурах до 490 ℃ не спричинить сильного окислення чи утворення оксидних шарів. Здатність відбити тепло і світло вдвічі вища за горячо-галужену цинкову стальну плиту, а коефіцієнт відбиття більше 0.75 є ідеальним енергозберігаючим будівельним матеріалом.

Електрогалужений цинковий підлог

Продукт, отриманий за допомогою запекання електрогалуженої цинкової листини з органічним покриттям, є електрогалуженою кольоровою листиною. Через тонкий цинковий шар електролистини, яка зазвичай містить 20/20г/м2 цинку, цей продукт не підходить для виготовлення зовнішніх стін і дахів. Проте через його красива зовнішність і відмінні технологічні властивості, його головним чином можна використовувати в побутовій техніці, аудіосистемах, стальній меблі, внутрішньому устаткуванні тощо.

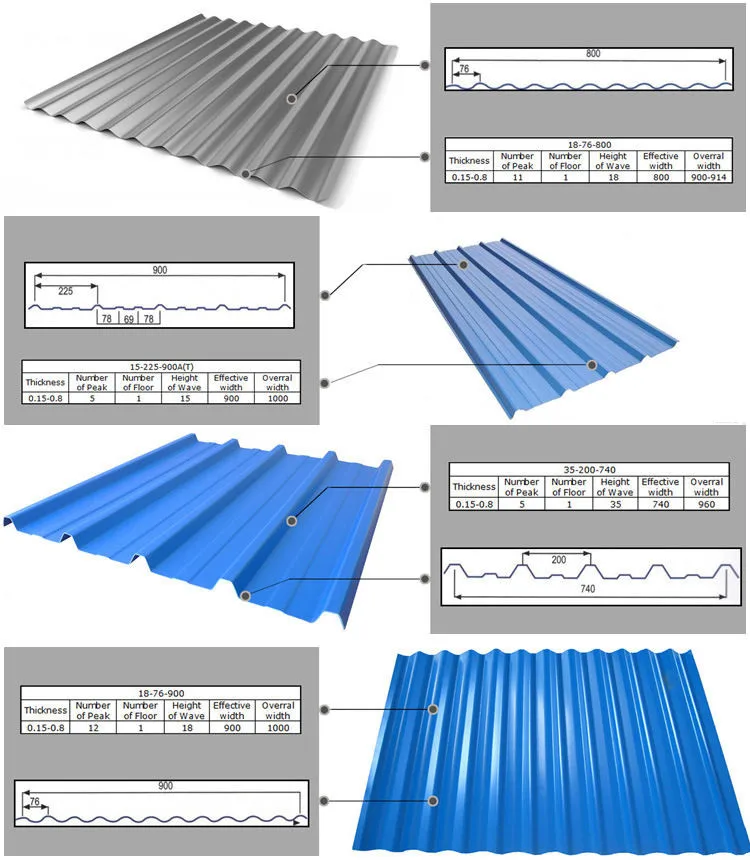

Гофрований листовий метал, також відомий як пресований листовий метал, зазвичай виготовляється з фарбованих оцинкованих стальних пластин, галузевих листів та інших металевих листів, які піддаються процесам катання та холодного гнуття для формування різних специфікацій випуклих-впуклих гофр.

Гофровані дошки мають хороші фізичні властивості та хімічну стійкість, такі як опору до вологоści та корозії, і широко використовуються в різних галузях, включаючи, але не обмежуючись, промислові та цивільні будівлі, дахи та стіни великопротяжних сталевих конструкцій, внутрішнє та зовнішнє украшання стін, а також як екологічно чисті матеріали для упаковки. Він має довгий термін служби та легкий у догляді, що робить його одним із витратних будівельних матеріалів.

Технічні характеристики:

| Стальний котушка PPGI | |

| Стандарт | ISO, JIS, AS EN, ASTM |

| Клас | Q195 Q235 Q345 |

| SGCC SGCH SGC340 SGC400 SGC440 SGC490 SGC570 | |

| SGHC SGH340 SGH400 SGH440 SGH490 SGH540 | |

| DX51D DX52D DX53D DX54D DX55D DX56D DX57D | |

| S220GD S250GD S280GD S320GD S350GD S400GD S500GD S550GD | |

| SS230 SS250 SS275 | |

| Ширина | 914мм до 1250мм |

| Товщина | 0,2мм до 2мм |

| Вага котушки | 3 тони до 6 тон |

| Ідентифікатор котушки | 30мм або 610мм |

| Вага котушки | 3~7 МТ |

| Ємність | 1,500,000МТ/рік |

| Доставка | 15-25 Днів |

| Основний матеріал | Горячооцинкована сталь/Холоднокатана сталь |

Швидкий огляд:

1.Фарбований рулон/PPGI/Гофрований лист/дахова плита

оцинковані рулони з кольоровим покриттям є легкими, естетично привабливими та мають хорошу корозійну стійкість. Їх також можна безпосередньо обробляти, головним чином використовуючи в рекламі, будівництві, побутовій техніці, електроприладах, меблів та транспортній галузі.

Призначено для дахів, стін та внутрішньо-зовнішнього оздоблення промислових та цивільних будівель, складів, спеціальних будівель та будівель із структур з великим пролітом.

Опис:

Специфікації:

Конкурентна перевага:

1. Невелика вага та висока міцність

2. Має відмінні антикорозійні характеристики та може ефективно захищати від навколишнього корозійного та оксидного впливу. При цьому стальний хвилястий лист також має добре тривалість та відносно довгий термін служби.

3. Стальний хвилястий лист має хорошу корозійну стійкість, стійкість до погодних умов, шумозаглушення та властивості запобігання загорянню, тому широко використовується в дахах, стінах будівель, теплоізоляції, гіdroзащиті та інших аспектах.

легкі, легко розрізати, позначити та встановити, що значно зменшує складність будівництва та економить час та вартість праці.

Наша дружня команда буде рада отримати від вас повідомлення!