| Place of Origin: | Shandong, China |

| Brand Name: | $560-600/TON |

| Model Number: | A106/A53GRB API5L/Q195,Q235,Q275,Q355,Q345,/SAE1010/1020,1045,etc |

| Certification: | API, CE, Bsi, RoHS, SNI, BIS, tisi, KS, JIS, GS, ISO9001 |

| Minimum Order Quantity: | 1TON |

| Price: | $560/TON |

| Packaging Details: | Exported Packaging Standard(In bundles, Nylon bags, wooden cases or as required) |

| Delivery Time: | 3-7days |

| Payment Terms: | FOB 30%T/T,70% before shipment |

| CIF 30% pre-payment and the balance to be paid before making shipment | |

| or Irrevocable 100% L/C at sight | |

| Supply Ability: | 10000 Ton/Tons per Month |

Description:

Galvanized steel pipe is divided into hot galvanized steel pipe and cold galvanized steel pipe

Hot dip galvanized pipe

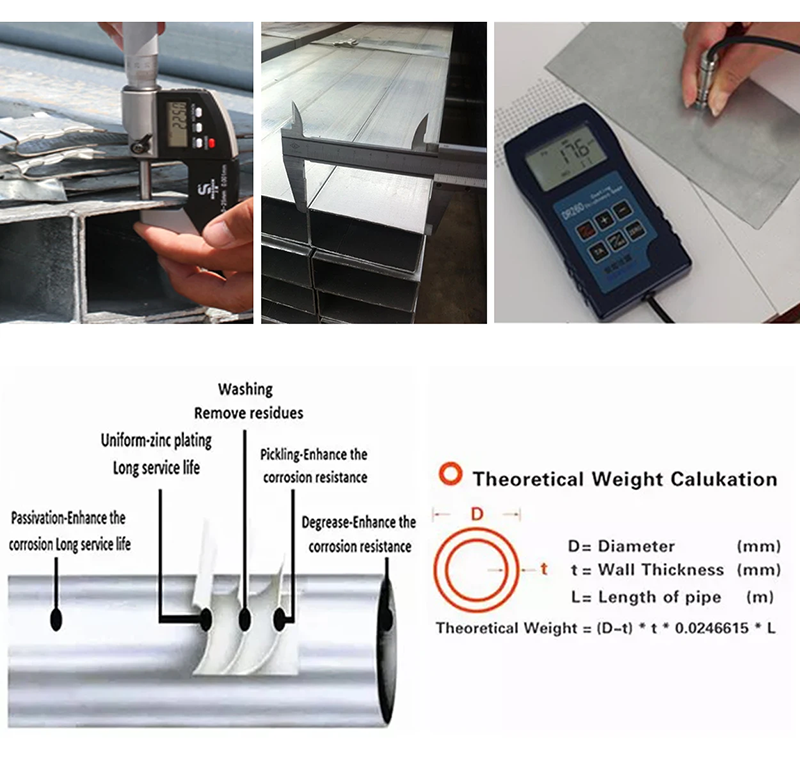

The molten metal is reacted with an iron matrix to produce an alloy layer, thereby combining the substrate and the plating layer. Hot-dip galvanizing is to pickle the steel pipe first, in order to remove the iron oxide on the surface of the steel pipe, after pickling, it is washed by ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then fed. Hot dip plating tank. Hot-dip galvanizing has the advantages of uniform plating, strong adhesion and long service life. Most of the northern processes use galvanized strips to directly coil the zinc

Cold galvanized pipe

Cold galvanizing is electrogalvanizing. The amount of galvanizing is very small, only 10-50g/m2, and its corrosion resistance is much worse than that of hot-dip galvanized pipes. Regular galvanized pipe manufacturers, in order to ensure quality, most do not use electro-galvanizing (cold plating). Only small companies with small equipment and old equipment use electro-galvanized steel, of course, their prices are relatively cheaper. In newly built houses, the use of cold-galvanized steel pipes as water supply pipes is prohibited.

Difference hot-dip galvanizing and cold galvanizing

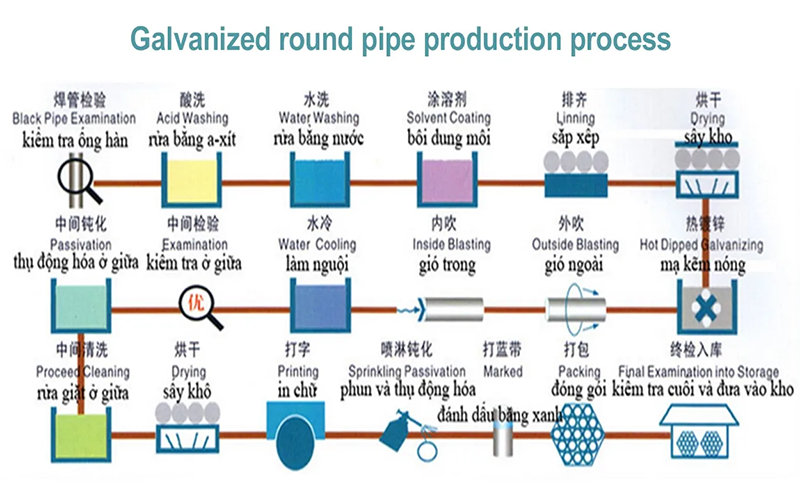

Hot dip galvanizing process:

Workpiece degreasing → washing → pickling → washing → drying solvent dip fluxing preheated hot dip galvanized → cooling → finishing → rinsing → drying → passivation test

Cold-galvanized process:

Chemical degreasing → washing → hot water hot water electrolysis degreasing → washing → washing → strong corrosive galvanized iron alloy → washing → washing → light → → washing → drying passivation

Advantages of galvanized pipes are following below:

Firstly, galvanized pipe after being hot dip galvanized surface can be protected, and inside the cavity of the pipe or any other coating the corner is difficult to enter, deepen the zinc can easily cover to the top, make whole galvanized pipe can be protected.

Second, after being galvanized pipe galvanized its impact resistance and anti-wear properties are very good, because the zinc coating hardness values larger than the hardness of steel, and therefore the impact resistance of hot-dip galvanized after and abrasion resistance is quite good. Furthermore galvanized biggest advantage is in the corner of the zinc layer will be relatively thick and good toughness and abrasion resistance, while other coatings are often in this corner of the thinnest most difficult construction, and therefore are vulnerable injury.

Specifications:

| l Description | l Galvanized Welded pipe | |

| l Steel grade | l Astm a53 Gr.B / ASTM A106 | |

| l Standard | l ASTM A106/A106M;ASTM A53/A53M;API 5L;GB/T 8163-2008;GB/T 8162-2008;BS1387, BS1139,EN39, EN1139, ASTM A53, JIS G3444 | |

| l Material | l A106 Grade A,A106 Grade B,A106 Grade C,A53 Grade A,A53 Grade B,API 5L Grade B,10#,20#,45# | |

| l Surface | l Hot-dip galvanising; Electro-galvanising; Customer requested method | |

| l Type | l 1. Pre-painted (zinc: 60-120G/M2)l 2. Hot-dipped galvanized (zinc: 120-500G/M2)l 3. Cold-dipped galvanized(zinc:10-50G/M2) | |

| l Size | l Wall thickness | l 1-22mm |

| Outer diameter | 21.3mm-610mm | |

| l Delivery time | l Prompt delivery or as the order quantity. | |

| l Package | l Standard export seaworthy package,or as required. | |

| l Application | l Conveying fluids; structural support; HVAC; oil and gas industry; industrial equipment | |

| l Contact | l If you have any questions,please feel free to contact me. | |

| l Container size | l 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 24-26CBMl l 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBMl l 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM |

|

Quick Detail:

1.gi pipe,Hot Dip Galvanized Round Steel Pipe, Galvanized Steel Pipe Galvanized Tube,welded gi steel pipe,gi steel tube

2.Hot dipped galvanized steel round pipe(HDG),is widely used in kinds of industry and building areas all over the world.

Cold galvanized pipe is electric galvanized, galvanized amount is very small, only 10-50g/m2, its own corrosion resistance is much different than hot galvanized pipe.

It can be used in construction,machinery, coal mine, chemical industry, electric power, railway vehicles, automobile industry, highway, bridge, container, sports facilities, agricultural machinery, petroleum machinery,prospecting machinery and other manufacturing industries.

| Chemical Properties % | |||||||||

| Grade A | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.25 | 0.27-0.93 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Grade B | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.3 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Grade C | |||||||||

| C | Mn | P | S | Si | Cr | Cu | Mo | Ni | V |

| 0.35 | 0.29-1.06 | 0.035 | 0.035 | 0.1 | 0.4 | 0.4 | 0.15 | 0.4 | 0.08 |

| Mechanical Properties | |||

| Grade A | Grade B | Grade C | |

| Tensile strength | 330 | 415 | 485 |

| Yield strength | 205 | 240 | 275 |

Description:

Galvanized welded pipe refers to a type of steel pipe that has been coated with a layer of zinc through a process called galvanization.

The galvanization process involves immersing the steel pipe in a bath of molten zinc, which forms a protective layer on the surface of the pipe.

The purpose of galvanizing welded pipes is to provide corrosion resistance and extend the lifespan of the pipe. The zinc coating acts as a barrier between the steel and the surrounding environment, protecting the pipe from rust and other forms of corrosion.

This makes galvanized welded pipes suitable for various applications, especially in industries where exposure to moisture or corrosive substances is common.

Some key benefits of galvanized welded pipes include:

1. Corrosion resistance: The zinc coating provides excellent corrosion resistance, making galvanized pipes suitable for outdoor and underground applications.

2. Durability: The combination of steel and zinc coating enhances the strength and durability of the pipe, allowing it to

withstand harsh conditions and heavy usage.

3. Cost-effectiveness: Galvanized welded pipes are generally more affordable compared to other corrosion-resistant alternatives,making them a cost-effective choice for various projects.

4. Easy installation: Galvanized welded pipes are relatively easy to install due to their standardized sizes and compatibility

with commonly used fittings and connectors.

5. Versatility: Galvanized welded pipes are available in various sizes and thicknesses, making them suitable for a wide range of applications, including plumbing, construction, agriculture, and industrial projects.

It is important to note that galvanized welded pipes have limitations. Over time, the zinc coating may degrade or wear off,

especially in highly corrosive environments. Therefore, regular inspection and maintenance are necessary to ensure the continued protection of the pipe.

Additionally, when working with galvanized welded pipes, it is important to take proper safety precautions, such as using

appropriate personal protective equipment and ensuring proper ventilation, as the galvanization process can release fumes that may be harmful if inhaled.

Applications:

construction,machinery, coal mine, chemical industry, electric power, railway vehicles, automobile industry, highway, bridge, container, sports facilities, agricultural machinery, petroleum machinery,prospecting machinery and other manufacturing industries.

Specifications:

| Galvanized Round Steel Pipe | |||||||||

| Stabdaed:API 5L,API 5CT,ASTM A53,ASTM A500,GB9711.1 Application:To be used for conveying gas,water,and petroleum for oil and natural gas industries and use for the structural steel pipes purpose Main Steel Tube Grade:GR.A,GR.B,GR.C,Q195,Q235B,Q345B and so on. |

|||||||||

| INCH | OD(MM) | Strandard Wall Thickness | |||||||

| SCH 10WT (mm) | SCH 20WT (mm) | SCH 40WT (mm) | SCH 60WT (mm) | SCH 80WT (mm) | SCH 100WT (mm) | SCH 160WT (mm) | XXS (mm) | ||

| 1/4” | 13.7 | 2.24 | 3.02 | ||||||

| 3/8” | 17.1 | 2.31 | 3.2 | ||||||

| 1/2” | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | 7.47 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | 7.82 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | 9.09 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | 9.7 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | 10.15 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | 11.07 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | 14.02 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | 15.24 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | |||||

| 4" | 114.3 | 3.05 | 4.5 | 6.02 | 8.56 | 13.49 | 17.12 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | 19.05 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | 21.95 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.7 | 15.09 | 23.01 | 22.23 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 | 25.4 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 | 25.4 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 | |

| 16" | 406 | 6.35 | 7.92 | 12.7 | 16.66 | 21.44 | 26.19 | 40.49 | |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 | |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 | |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | ||

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 | |

| 26" | 660 | 7.92 | 12.7 | ||||||

| 28" | 711 | 7.92 | 12.7 | ||||||

| 30" | 762 | 7.92 | 12.7 | ||||||

| 32" | 813 | 7.92 | 12.7 | 17.48 | |||||

| 34" | 863 | 7.92 | 12.7 | 17.48 | |||||

| 36" | 914 | 7.92 | 12.7 | 19.05 | |||||

| 38" | 965 | ||||||||

| 40" | 1016 | ||||||||

| 42" | 1066 | ||||||||

| 44" | 1117 | ||||||||

| 46" | 1168 | ||||||||

| 48" | 1219 | ||||||||

Competitive Advantage:

We have competitive prices and timely delivery advantages in the supply of seamless steel pipes, not only for volume customers, but also accept customer orders for sample personalized design, specifications and packaging requirements.

Our friendly team would love to hear from you!